Miscellaneous Data

concrete, cement, cu, wool, mortar and water

In using wool for insulation or deafening, in connection with brick walls or partitions, fur ring strips can be used, and the wool packed in two inches thick behind the lath.

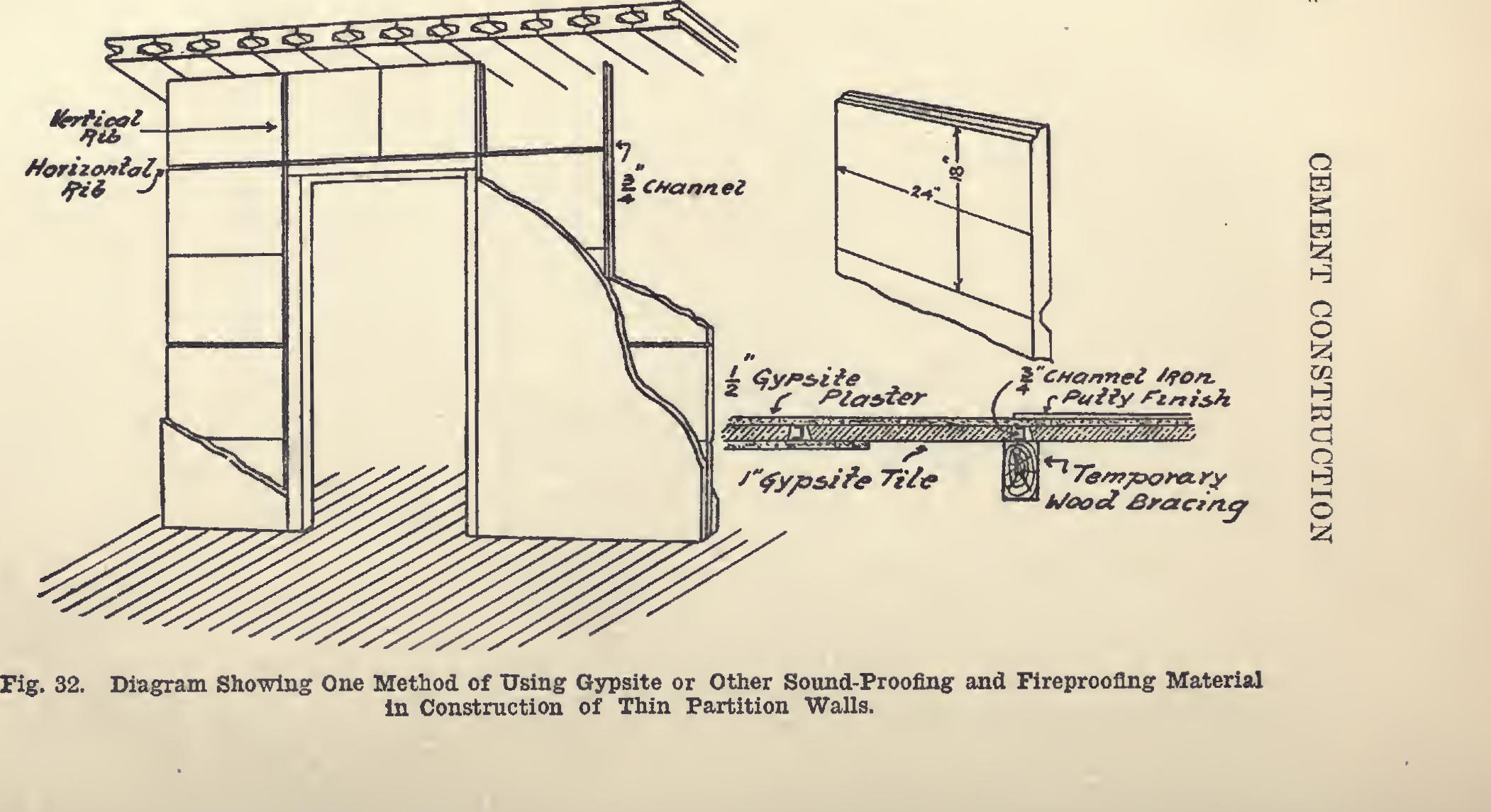

In roofs, the mineral wool can be packed be Fig. 32. Diagram Showing One Method of Using Gypsite or Other Sound-Proofing and Fireproofing Material in Construction of Thin Partition Walls.

KoLEDn11ISKOD INHNHO tween the rafters by sheathing underneath them, beginning at the eaves and working toward the ridge, packing in the wool as the sheathing is done. A minimum thickness of two inches will be found very effective in making the rooms comfortable that are next to the roof (see Fig. 31).

A high grade of mineral wool, combined with degummed flax fiber to give it strength, is manufactured into board form for insulating purposes.

The well-known fibrous rock, asbestos, is also manufactured in a variety of forms and combi nations with other materials, for similar pur poses; and there are also on the market a great number of special, patented, insulating mate rials in board and fabric forms (Plaster Board, Gypsinite, etc.), comprising felt, combinations of felt with building paper or plaster, or of wood with gypsum products, etc. Figs. 30 and 32 give some suggestions as to the manner of using various insulating materials in the con struction of partition walls.

For fireproofing interior walls, veneering floors, etc., a form of concrete known as pulp concrete is sometimes used. This is simply con crete in which wood pulp or sawdust is used as the aggregate mixed with the sand and cement. This form of concrete is never employed for out door work. It is of low tensile strength, and is much lighter than ordinary concrete. On ac count of its elasticity, combined with its prac tically non-absorbent character, it is especially used as a floor veneering for saloons, markets, butcher shops, etc. It may be laid without joints in a continuous layer inches deep, upon paper spread over the floor that is being treated. The customary proportions for mixing are 1 part cement, 2 parts sand, and parts pulp or sawdust. If an excess of pulp is used,

the concrete becomes absorbent.

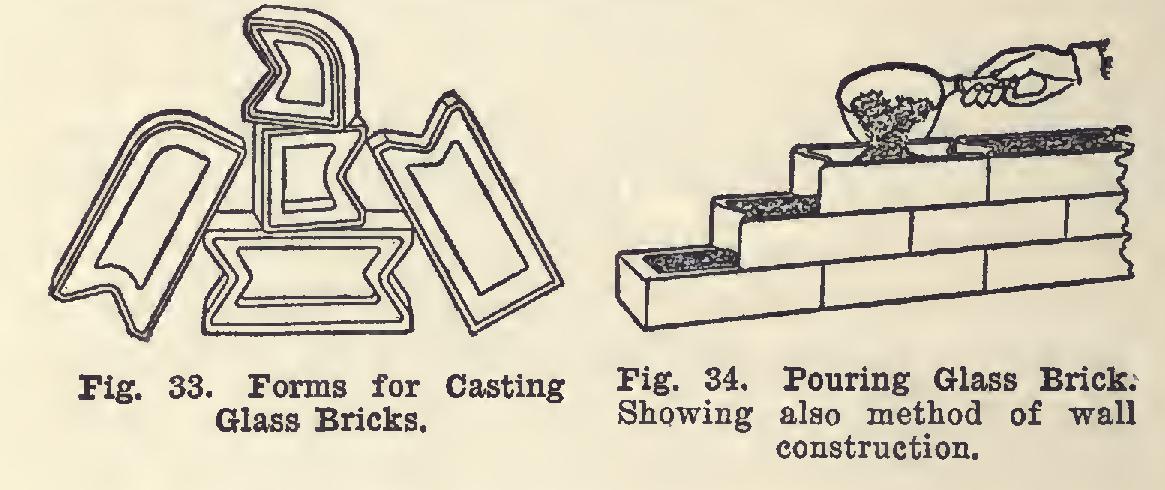

Glass Brick. A combination of glass and concrete has recently been developed for con struction work, in the shape of brick consisting of glass moulded into various hollow shapes and filled with concrete. Forms for casting these bricks in various shapes are illustrated in Fig. 33, while Fig. 34 shows method of pouring them full of concrete, also one manner of laying them in Wall construction. The bricks have indented ends, and may be laid up with narrow mortar joints, when desired. The construction is said to be remarkably free from tendency to open joints from settling, and is also claimed to be waterproof.

Frigite

is a crystalline compound dissolved in the water for mixing concrete. It prevents freezing under any temperatures likely to be met with, and is claimed to allow normal setting and hardening during freezing weather, and to add materially to the strength of concrete.

How to Make Cement Mortar Adhere.

Some contractors have difficulty in causing cement mortar to adhere to finished cement work, and to stone and brick work. To do this properly, soak the surface of the old work thoroughly with water, dust on a little neat cement, and follow this with a mortar coat before the dusted cement has set. Or apply a thick paint of neat cement and water to the old work after the work has been thoroughly soaked; this paint forms a binder; apply mortar coat promptly, before the coating of neat cement paint has set.

For Ready Reference.

The following miscel laneous data may frequently be found of value for ready reference in solving problems, making estimates, settling disputed questions, etc.: 1,728 cu. in. make 1 cu. ft.

27 cu. ft. make 1 cu. yd.

1 lb.=27.681 cu. in. of distilled water.

A gal. of water at 62° Fahrenheit weighs 8.3356 lbs.

A cu. ft. contains 7.4805 gals. at 62° Fahren heit.

To find the diameter of a circle, multiply cir cumference by .31831, To find circumference of a circle, multiply diameter by 3.1416.