Mixing of Concrete

board, sand, cement, fig, feet, shown and gravel

The essential thing in all cases is to see that the mass is turned a sufficient number of times to insure a thorough mixture.

The following account of the mixing of a small batch of concrete—condensed from a de scription given by Messrs. Wilson and Gaylord— will serve as a general illustration of details of procedure in ordinary practice on small jobs. The mixture is a 2-bag batch of 1:2:4 concrete, and two men are suffieient for the work.

The Concreting Plant.

The batch will be mixed on a wooden platform known as a con crete board. For two men, this should be 9 feet by 10 feet for a 2-bag batch, or 12 by 10 feet for a 4-bag batch. Make it out of 1-inch boards, 10 feet long, surfaced on one side, using five 2 by 4-inch by 9-foot cleats to hold them together. The boards are so laid as to enable the shoveling to be done with, and not against, the cracks be tween the boards. The boards must be drawn up close in nailing, so that no cement grout will run through while mixing. If tongued-and grooved boards are available, so much the better. Knot-holes may be closed by nailing a strip across them on the under side of the board. It is a good precaution against losing cement grout, to nail a 2 by 2-inch or 2 by 4-inch piece around the outer edge of the board. Often 2-inch planks are used in making concrete boards, but these are unnecessarily heavy, and very cumbersome to move (see Plate 3).

The concrete board is usually best placed as close as possible to the forms in which the con crete is to be deposited, but local conditions must govern this point. Choose a place giving plenty of room, near the storage piles of sand and stone (or gravel). Block up your concrete board level, so that the cement grout will not run off on one side, and so that the board will not sag in the middle under the weight of the concrete.

Make the runways for the wheelbarrows of good, strong plank 2 to 3 inches thick and 10 to 12 inches wide. They should be of liberal width —say at least 20 inches wide if lifted much above the ground—as this feature will help greatly to lighten and quicken the work.

In addition to board and runs as described above, the concreting outfit will include the fol lowing tools: Shovels, No. 3, square point; wheelbarrows, at least two being necessary for quick work (sheet-iron body preferred) ; rake; water barrel; water buckets, 2-gallon size; tam per, 4 by 4 inches by 2 feet 6 inches, with handles nailed to it, as shown in Plate 3; garden spade, or spading tool cut from a board and beveled to a thin edge at the bottom, as shown in the hands of the man on the concrete board, Plate 3, or in Fig. 12; and a sand screen, made by nailing

a piece of 1/4-inch-mesh wire screen ft. by 5 ft. in size to a frame made of 2-in. by 4-in. stuff.

Mixing. With the mixing board placed and the "runs" made, the concrete plant is ready.

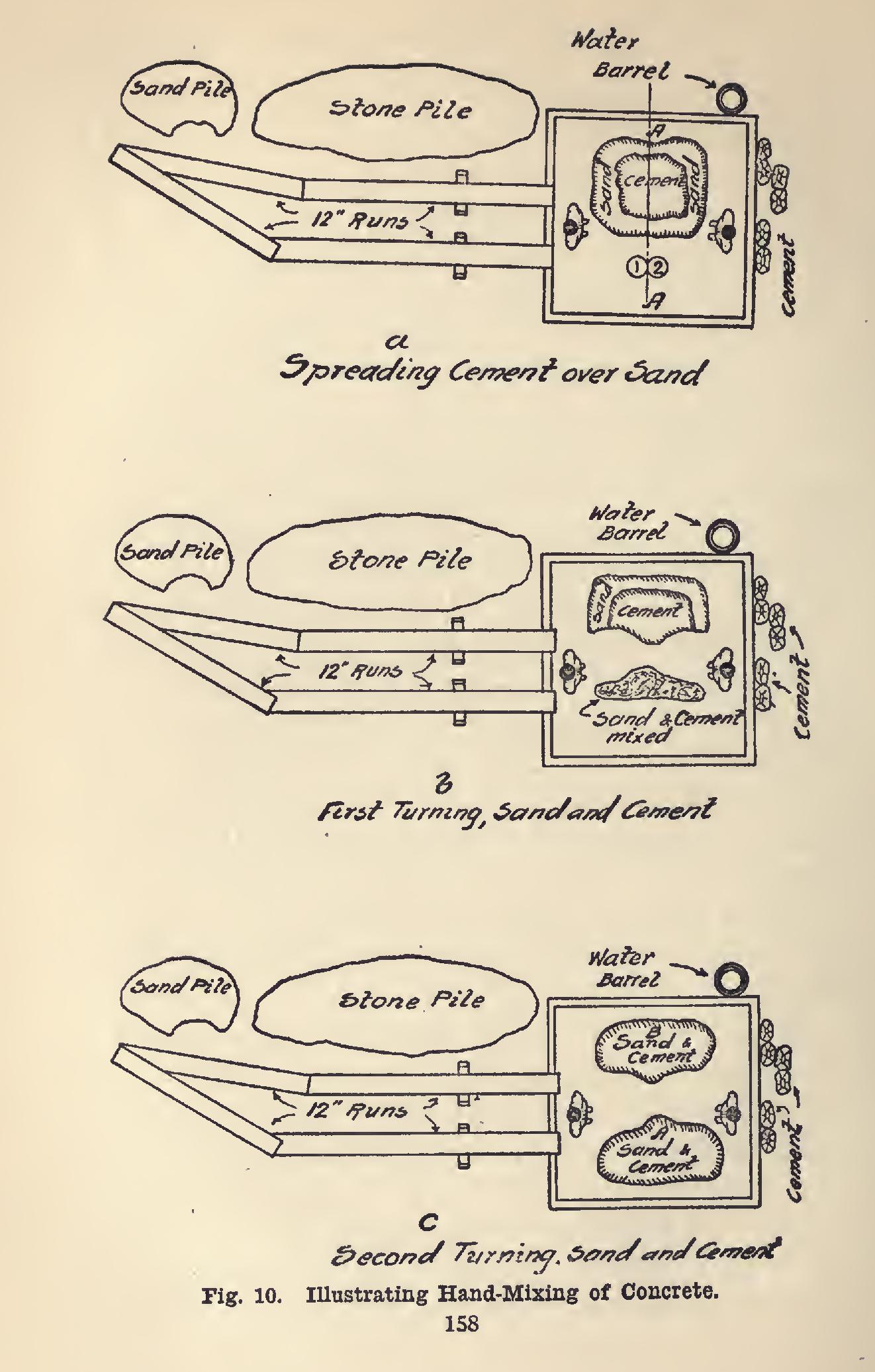

First load your sand in wheelbarrows from the sand pile, wheel onto the board, and fill the sand-measuring box, which is placed about two feet from one of the 10-foot sides of the board. When the sand box is filled, lift it off, and spread the sand over the board in a layer 3 or 4 inches thick, as shown in Fig. 10 (a). Take the two bags of cement, and place the contents as evenly as possible over the.sand (a, Fig. 10). With the two men standing at points indicated, start mix ing the sand and cement, each man turning over the half on his side of the line A-A. Starting at his feet and pushing the shovel away from him, each man takes a full shovel-load, and turns the shovel over at the points marked 1 and 2. In turning the shovel, do not simply dump the sand and cement at the points marked 1 and 2 in the diagram, but shake the materials off the end and sides of the shovel, so that the sand and cement are mixed as they fall. This is a great assist ance in mixing these materials. In this way the material is shoveled from one side of the board to the otLer, as shown in Fig. 10 (b and c). Fig.

10 (b) shows the first turning; and Fig. 10 (c), the second turning.

The sand and cement should now be well mixed and ready for the stone and water. After the last turning, spread the sand and cement out carefully; place the gravel or stone measuring box beside it as shown in Fig. 11 (a) ; and fill from the gravel pile. Lift off the box, and shovel the gravel on top of the sand and cement, spreading it as evenly as possible. With some experience, equally good results can be obtained by placing the gravel measuring box on top of the carefully leveled sand and cement mixture, and filling it, thus placing the gravel on top with out an extra shoveling. This method is shown in Fig. 11 (b).