Mixing of Concrete

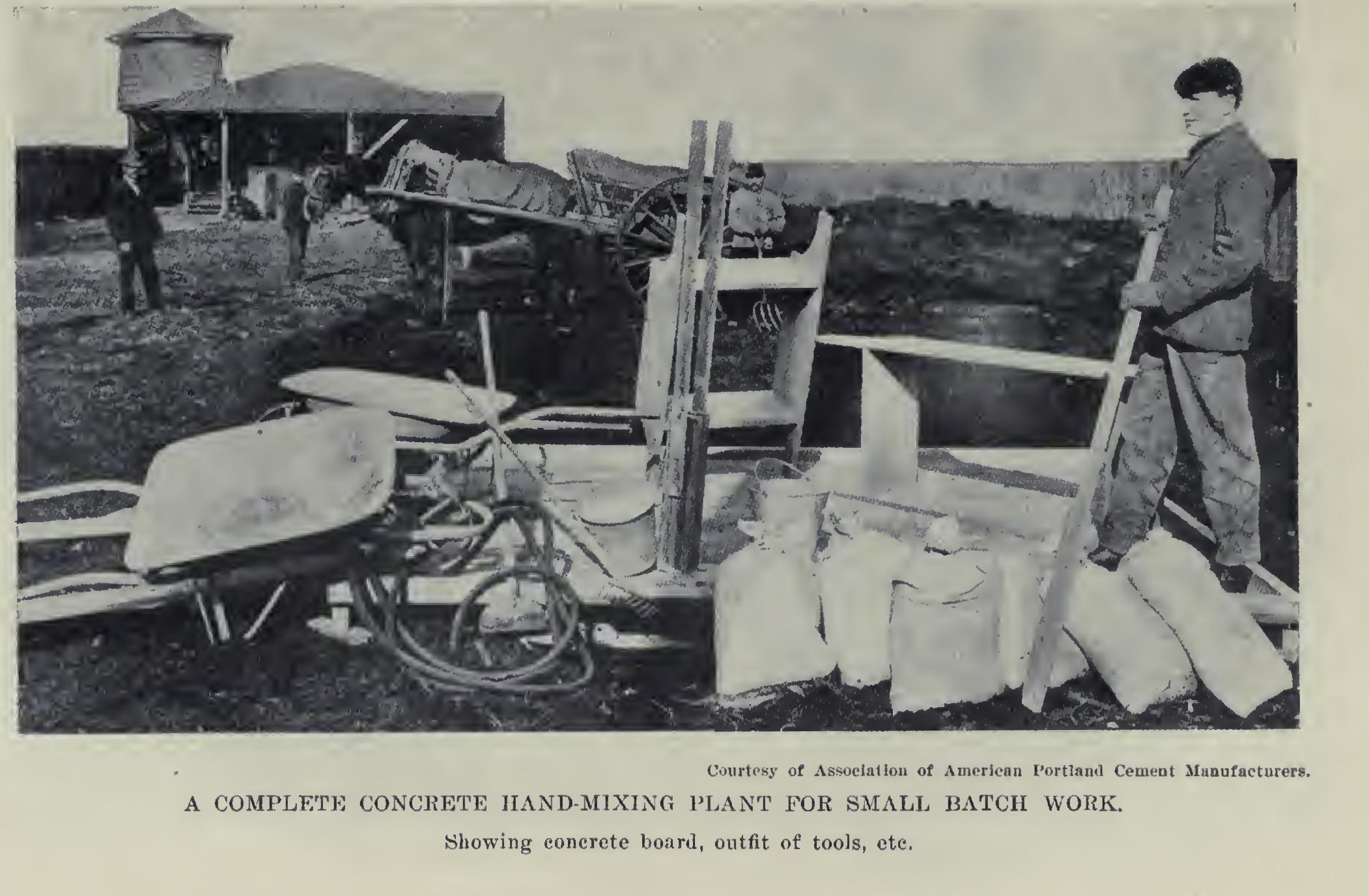

sand, water, gravel, board, cement, mix, batch, shovel and setting

Now add about three-fourths the required amount of water, using a bucket, and dashing the water over the gravel on top of the pile as evenly as possible. Be careful not to let too much water get near the edges of the pile, as it will run off, taking some cement with it. This caution, however, does not apply to a properly constructed mixing board, as the cement and water cannot get away.

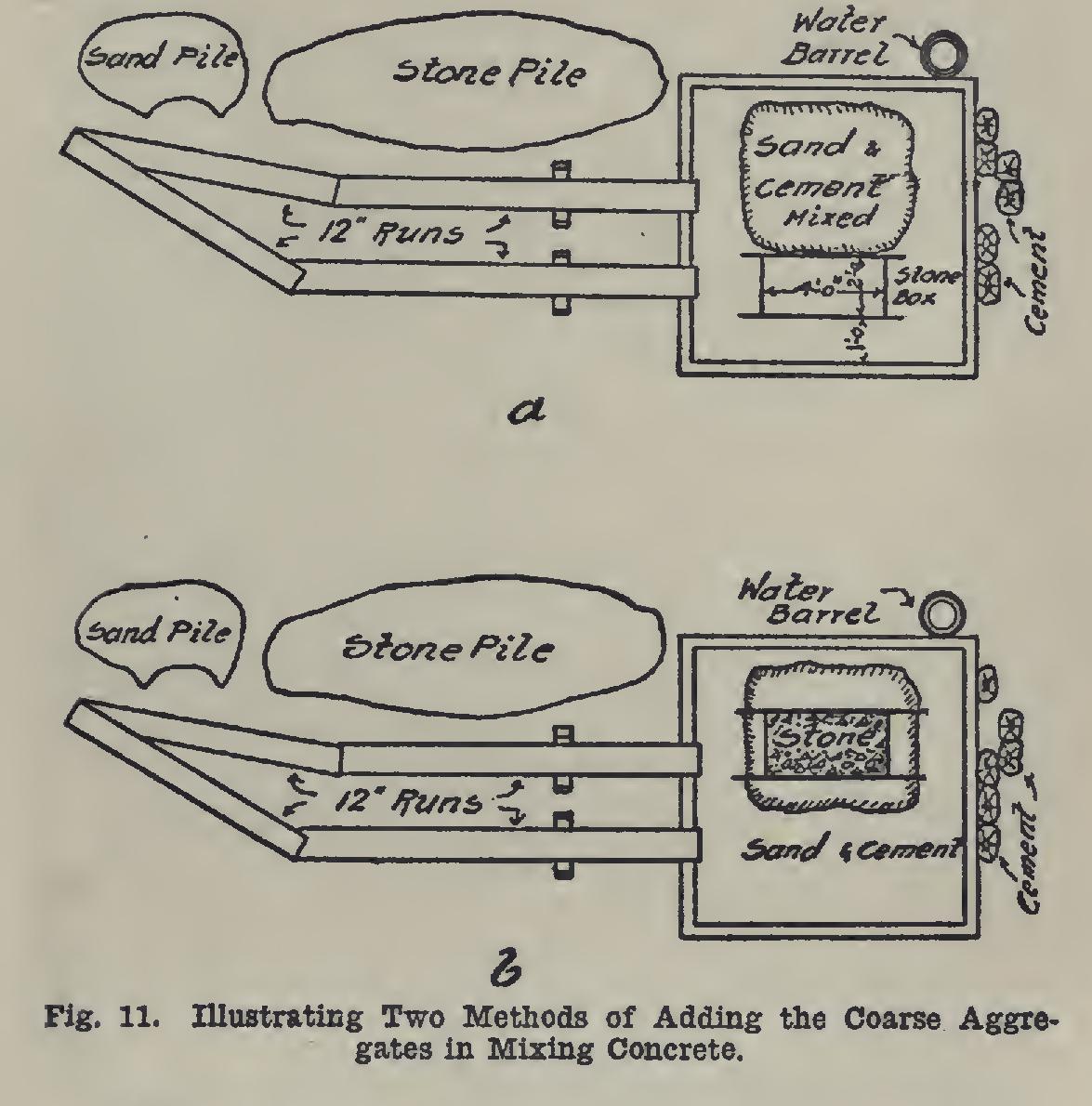

Starting the same as with the sand and ce ment, turn the materials over in much the same way, except that, instead of shaking the ma terials off the end of the shovel, the whole shovel load is dumped as at points 1 or 2 (a, Fig. 10), and dragged back toward the mixer with the square point of the shovel. This mixes the gravel with the sand and cement, the wet gravel picking up the sand and cement as it rolls over when dragged back by the shovel. Add water to the dry spots as the mixing goes on, until all the required water has been used. Turn the mass back again, as was done with the sand and cement.

With experienced laborers, the concrete would be well mixed after three such turnings; but'if it shows streaky or dry spots, it must be turned again. After the final turning, shovel into a compact pile. The concrete is now ready for placing.

When the sand and gravel are found already mixed, as in a natural bank, spread out the mix ture of sand and gravel as much as the board will readily permit; add enough water to wet the gravel and sand thoroughly; spread the cement evenly in a thin layer over the sand and gravel; and turn over, as described previously, at least three times, adding the rest of the water neces sary to get the required consistency while the materials are being turned. It requires some experience to work up a natural mixture of bank sand and gravel; and, if at all doubtful about the concrete made from it, first screen the sand from the gravel, and then mix in the regular way.

Number of Men.

For the above operation, only two men are required, although more can be used to advantage. If three men are avail able, let two of them mix as described above, and let the third man supply the water, help mix the concrete by raking over the dry or unmixed spots as the two mixers turn the concrete, help load the wheelbarrows with sand and stone or gravel, etc.

If four men are available, it is best to increase the size of the batch mixed to a four-bag batch, doubling the quantities of all materials used. The cement board should also be increased to 10 feet by 12 feet. In this case, start the mixing in the middle of the board, each pair of men mix ing exactly as if for a two-bag batch, except that the concrete is shoveled into one big mass each time it is turned back onto the center of the board.

When more than four men are available, the rest may place the concrete, make new runs, load wheelbarrows, etc., taking the concrete

away from the board as fast as it is mixed. In this case, another small concrete board should be placed next to the big board, so that in the last turning the batch can be shoveled over onto the small board for placing, making room on the big board to mix the next batch. The small platform need be only just big enough to hold the pile of mixed concrete.

Measuring by Wheelbarrow.

With a little practice, the sand and stone or gravel can be measured by the number of wheelbarrow loads almost as accurately as by means of the measur ing boxes.

If the concrete has to be wheeled not over 50 feet, four experienced men should be able, on an average, to mix and wheel to the place of deposit about 10 four-bag batches of 1:3:6 con crete in 10 hours And since, from Table XII, one 4-bag batch will make 24 cubic feet of con crete, the four men should mix and wheel in this period of time about 240 cubic feet of concrete, or 240-i-27=8.8 cubic yards. This estimate, however, is for the very simplest kind of con creting, and makes no allowance for the labor of supplying materials to the mixing platform or for building forms.

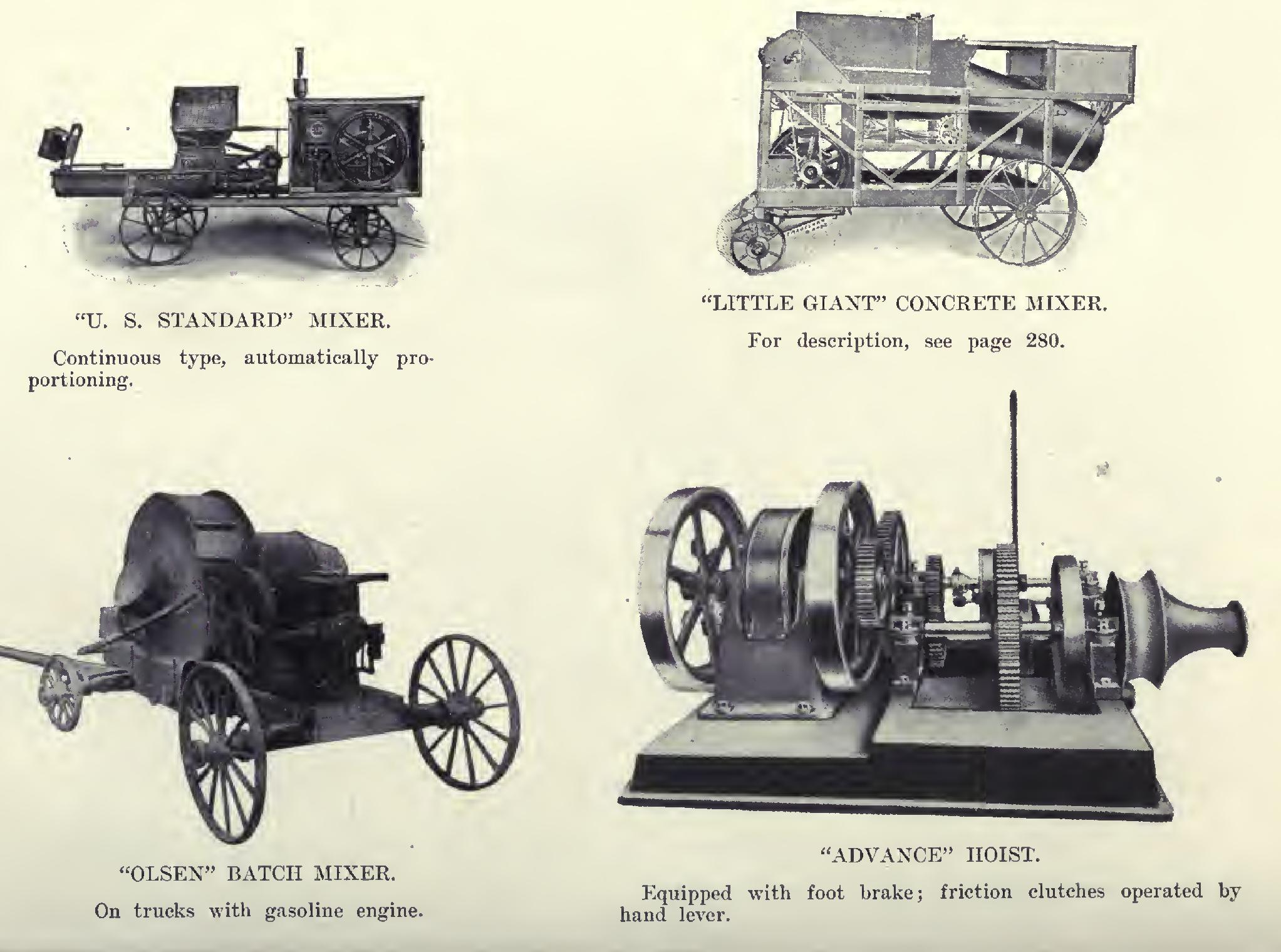

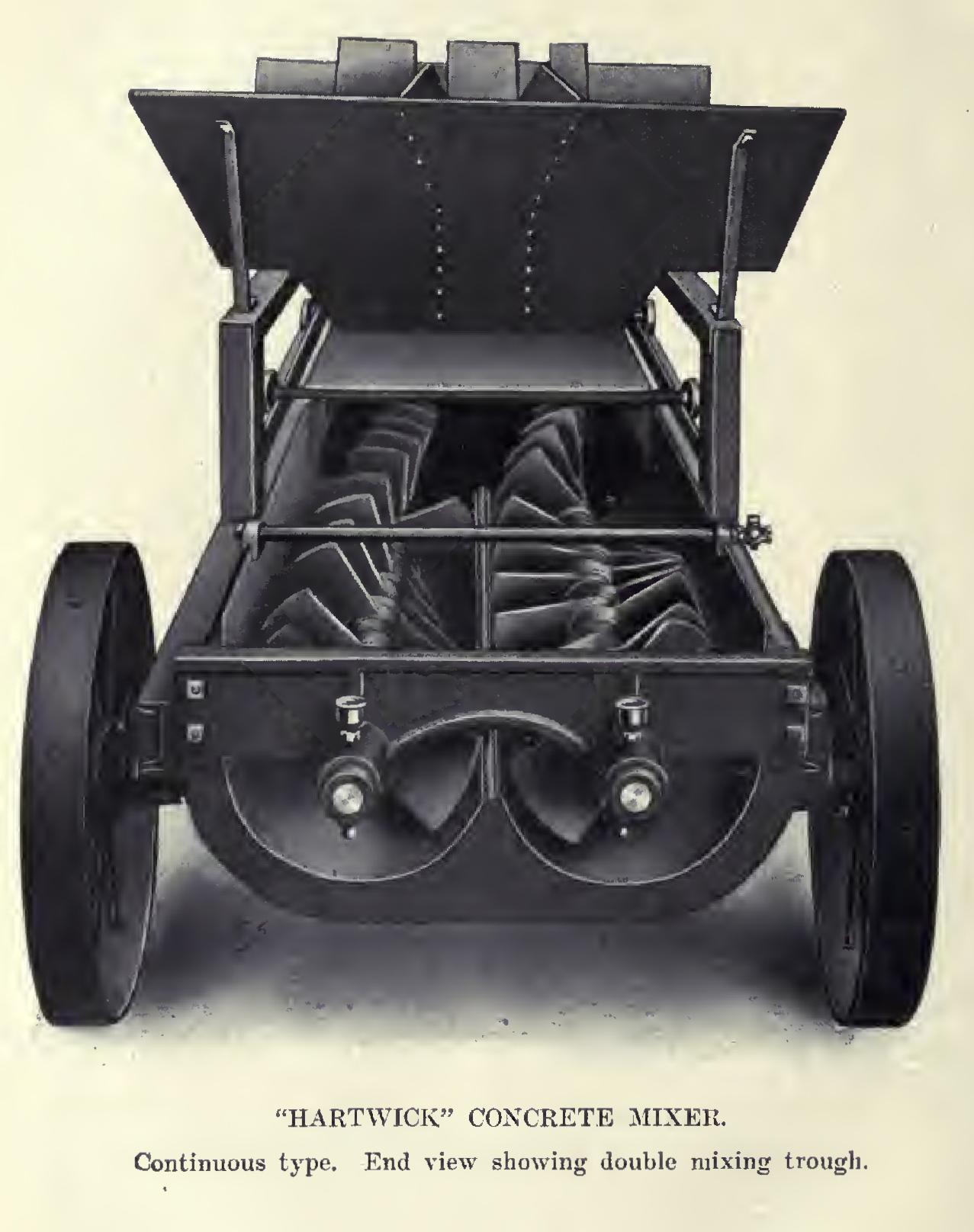

Mixing by Machinery.

The details of ma chine mixing will be taken up later in connection with the description of the various types of con crete mixers, under the head of "Concreting Machinery and Tools." To Regulate Setting and Hardening. As already explained, some regulation of the time of setting of cement can be accomplished by regulating the consistency of the mixture, a dry mixture setting more quickly than a wet one. Also, since concrete sets more rapidly in warm than cold weather, the setting may be regulated to some extent by simulating the proper weather conditions. This may be done by constructing a light framework over the job, covering it with canvas or other material, and regulating the tem perature within by means of stoves. This method, however, is very expensive, and is used only in building construction, being employed then chiefly as a protection to the concrete dur ing the setting process in freezing weather.

When it is desired to obtain a very rapid set ting and hardening, as in making casts and orna mental forms, a 10 per cent solution of calcium chloride may be used instead of water, for mix ing and pouring. This material is cheap, and can be obtained from any dealer in chemicals, or in large quantities from manufacturing chem ists. A 10 per cent solution is obtained by dis solving 8 pounds of calcium chloride in 10 gal lons of water. Artificial stone made in this way will harden, and can be removed from moulds or forms, in one-third the time required when only water is used for mixing. The chemical is said to have no injurious effect whatever on the strength or soundness of the cement.