Standard Specifications for Cement

water, ball, hours, boiling, testing, inches and test

If the minimum strength is not specified, the mean of the above values shall be taken as the minimum strength required.

Constancy of Volume.

Pats of neat cement about three inches in diameter, one-half inch thick at the center, and tapering to a thin edge, shall be kept in moist air for a period of 24 hours. One pat shall then be kept in air at nor mal temperature, and observed at intervals for at least 28 days. Another pat shall be kept in water maintained as near 70 degrees F. as prac ticable, and observed at intervals for at least 28 days. A third pat shall be exposed in any con venient way in an atmosphere of steam, above boiling water, in a loosely closed vessel, for 5 hours (see Fig. 6).

These pats, to satisfactorily pass the require ments, shall remain firm and hard, and show no signs of distortion, checking, cracking, or disintegration.

Sulphuric Acid and Magnesia. The cement shall not contain more than 1.75 per cent of anhydrous sulphuric acid nor more than 4 per cent of magnesia (Mg0).

Easily-Made Testing Apparatus Mr. W. Purves Taylor, engineer of the Municipal Testing Laboratories of Philadelphia, Pa., has devised simple methods of testing that in a general way are suited to the requirements of cement users, and for which all the necessary apparatus can easily be made by anyone of ordinary mechanical ability. These simple methods of testing are described as follows: Soundness. Take about half a pound of cement, place it on a clean surface of metal or glass, and form it into a crater. Into the center of the crater pour about a fifth of its weight of water, and mix thoroughly by hand or with a trowel for a couple of minutes, until a stiff and uniform paste is obtained. Make a ball of the paste about 2 inches in diameter, and drop it on the table from a height of about 2 feet. If the ball flattens more than half its depth, the paste is too wet; if it cracks badly, it is too dry. If necessary, add more cement or more water, mix thoroughly, and test until the right consistency is obtained; then mould two balls about 2 inches in diameter.

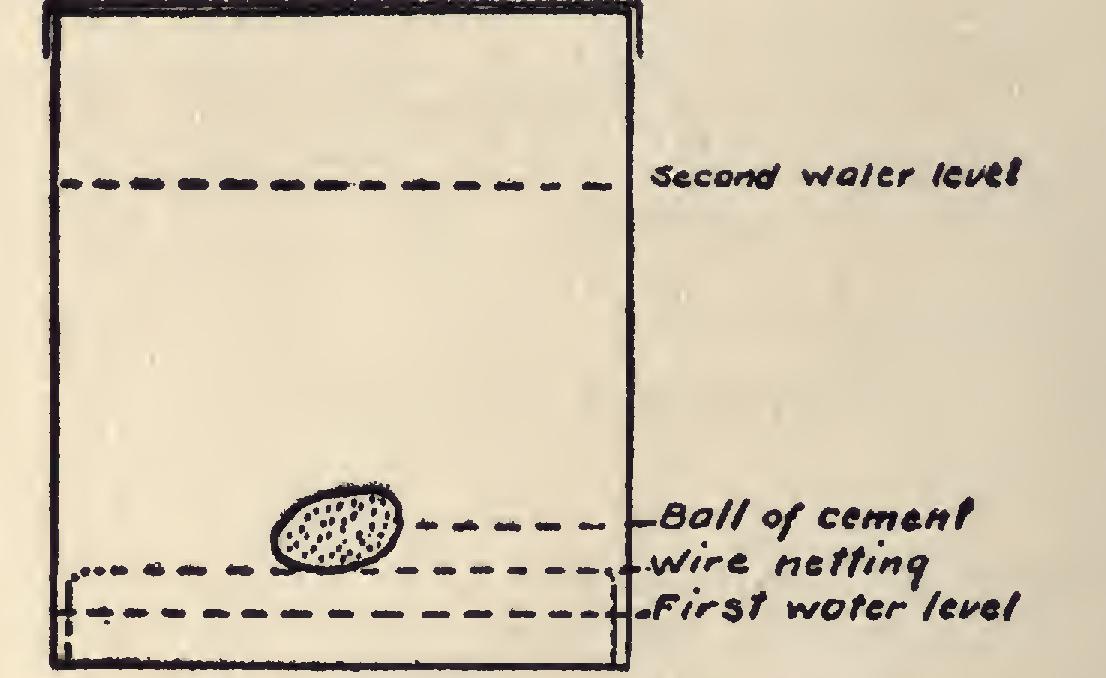

Fig. 7. Method of Testing for Soundness.

Take a tin can which has a tightly fitting cover, and bend into it a piece of wire netting, as shown in Fig. 7, about 2 inches from the bot tom. Put about an inch of water in the bottom

of the can, place one of the balls on the netting, cover the can, and put it away in a cool place for 24 hours. Then fill the can with water to cover the ball, remove the cover, and place the can on a stove at such a heat that the water will boil in about half an hour. Let it boil gently then for three hours. Have a second vessel of boiling water beside the can; and, as the water evaporates from the first vessel, replace it with the boiling water from the second one. Never add cold water. After boiling three hours, remove the ball, and examine it.

A good Portland cement will always pass this test, and the ball will remain sound and hard. If the ball is disintegrated, or if it is checked or cracked, it generally indicates in ferior quality and untrustworthy material. Sometimes failure in boiling is caused by the material being too fresh, and, on a second test made a month or so later, the cement will pass, showing that the expansive elements have be come hydrated and thus inert. In general, how ever, it is on the safe side never to use cement that fails in boiling. If it fails at first, store it away for a month, and then test again. If it still fails, it is better not to use it.

Time of Setting. Put the second ball, made as previously described, in a place protected from the sun or any other source of heat, and from any strong current of air. At the end of twenty minutes, examine it; then put it away, and examine it again in ten hours. The ball, at twenty minutes, should still be soft and pli able, damp on the surface, and should not feel warm. At ten hours it should be dry, firm, and hard enough so that a firm pressure of the thumb nail will make no impression on it. If the cement begins to harden or feel warm in less than twenty minutes, it is generally inad visable to use it, since setting will have begun before the mortar or concrete is moulded, and the result will be a weak and easily disinte grated product. It is, of course, possible to retemper such cement and obtain excellent results; but this process requires considerable skill and experience, and therefore is not usually to be recommended; moreover, it always means at least some slight loss in strength.