Standard Specifications for Cement

mortar, moulds, strength, center, exactly, shown, days and prisms

Quick-setting cement often becomes slower by storage for a month or two, so that it may be better to keep such material for that length of time than to attempt to use it earlier at the risk of poor results. A cement that does not harden in ten hours may ultimately give good results; but the slow setting will much delay the progress of the work, and may cause injury in removing the moulds or striking the centers. Safe prac tice will require cement to set between the stated limits.

Purity. Take as much cement as may be lifted on a five-cent piece, and place it in a china or glass dish. Pour on it a mixture of 1 part of water and 3 parts of muriatic (hydrochloric) acid; using a quantity equal to about three times the volume of cement. Pure Portland cement effervesces violently for a second or two, and then forms a yellowish jelly. A continued effer vescence shows adulteration with limestone or natural cement. Cinders or sand, if present, will be shown in a sediment at the bottom of the jelly. The presence of slag is shown by the characteristic putrid odor of hydrogen sulphide (sulphuretted hydrogen). Cement containing any of these adulterations or impurities should not be used.

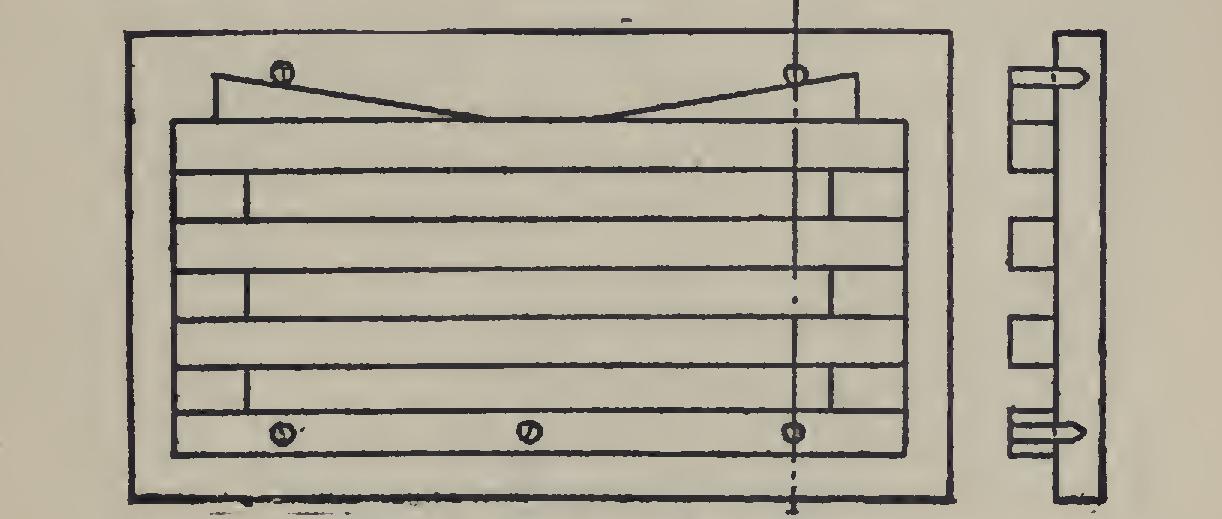

Fig. S. Moulds for Simple Tests.

Strength. It is hard to determine the strength of a cement mortar by any simple method, and obtain results of even approximate accuracy. The following, however, is probably the best simple method: Make a mould, as shown in Fig. 8, of a planed board and some one-inch strips of wood. Fasten the top strip to the board, and the others on loosely, in the manner indicated in the dia gram, holding them in place by the wedges at the bottom, thus forming moulds for three prisms or bars of mortar 1 inch by 1 inch by 12 inches long. Take special care that the cross sections of the prisms are exactly one square inch.

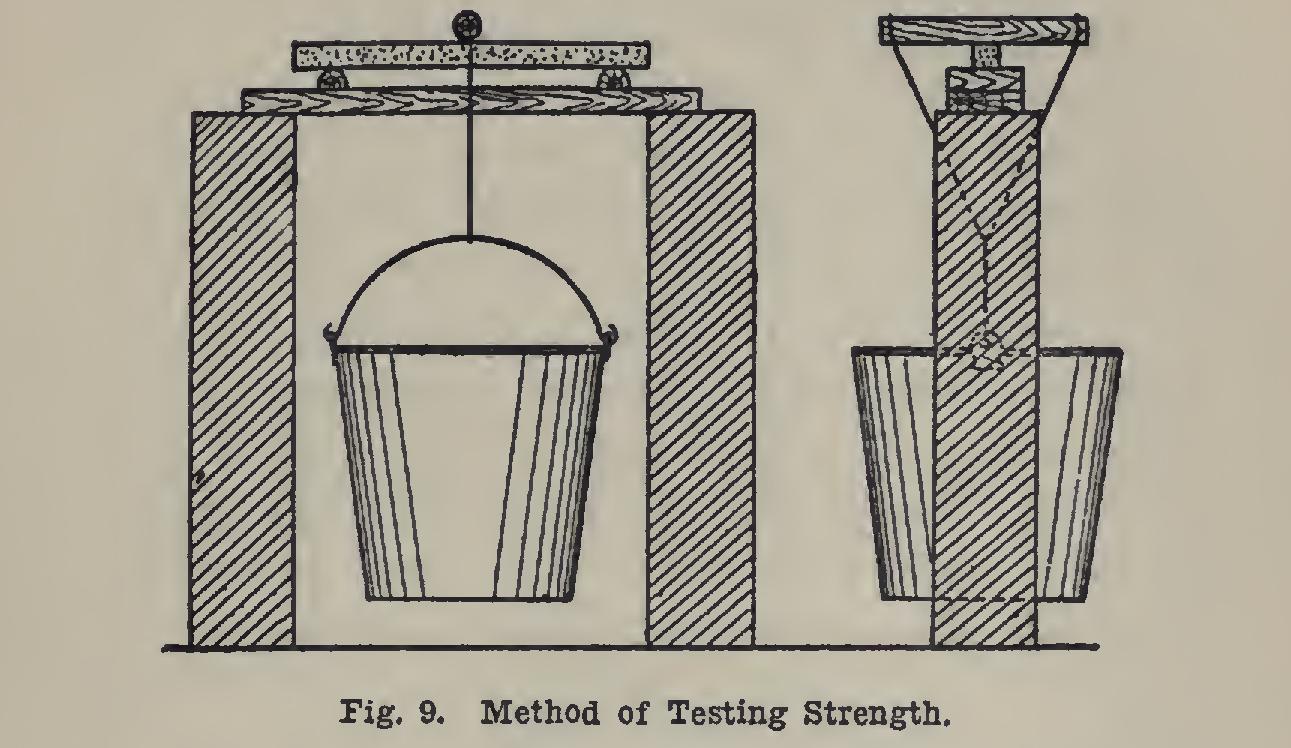

Take mortar from the mixing box, or make some of 1 part cement and 3 parts sand, thor oughly mixed dry and then wetted to form a stiff mortar; and fill the moulds, pressing the material in firmly, and smoothing the tops with a trowel. The moulds should be oiled slightly to prevent mortar from sticking. Put the moulds away in a cool and, if possible, a damp place, for 24 hours. Then remove the prisms of mortar, and place them in fresh water, neither hot nor cold, for 6 or for 27 days. Any prisms that are chipped or otherwise defective should be discarded. Make the apparatus shown in Fig. 9 with a board, a round piece of wood about an inch in diameter, and a pail. The bottom

bearing edges are made by cutting the round piece of wood in half, and are fastened to the board exactly 10 inches apart, center to center. The center bearing is a round piece of wood from which a pail is suspended by a cord.

When the test pieces are 7 or 28 days old, place them, still wet, on the apparatus as shown in the cut, taking care that the upper strip is exactly in the center and at right angles with the prism. Adjust the pail so that it is just off the ground and exactly under the specimen; and then slowly pour sand into it until the prism breaks. Carefully weigh the bucket, with the cord and strip still attached; this will indicate the load that stressed the bar to the failing point. If the prism is not exactly one inch square, cor rect the weight by dividing it by the product of its width times the square of its depth in inches.

The approximate strength of the mortar may then be computed as follows: Tensile strength equals center load multi plied by 10.

Compressive strength equals center load mul tiplied by 50.

If the average of three prisms tested in this manner shows a tensile strength of less than 120 pounds at 7 days, or 180 pounds at 28 days, on 1:3 mixture, something is radically wrong with either the cement or the sand, and the fault should be thoroughly investigated.

Tests made by this method are, of course, far from being accurate, but nevertheless give a very fair indication of the value of the material. In determining the relative value of different sands intended for use, they will often give most valuable and useful information.

Crude as these tests may be said to be, they are vastly superior to no tests at all, and should be of much assistance to the small user in secur ing good material. Insist on cement that will boil and set normally, and most of the dangers of inferior cement will be avoided.

Another simple method of testing by which the user may ascertain the soundness of the cement he purposes to use, is as follows: Make three cakes of cement, thicker in the middle than on the edges. Allow one to remain in moist air for 24 hours, and then steam it 4 hours. The second cake should be exposed in moist air, and the be immersed in water. The results in the case of the second and third cakes should be noted at intervals during 28 days. If the cement is sound, it will not disinte grate; but if it shows expansion cracks on the edges of any of the cakes, it is not sound.