Erection of Reinforced Structures

concrete, set, structure, finished and steel

ERECTION OF REINFORCED STRUCTURES The erection of a reinforced structure is simi lar to the making of a casting in a large foundry.

Forms or patterns are built to correspond ex actly with the lines of the finished work, the reinforcing steel is set in place, and the concrete is poured into the forms. The whole structure is thus built as a monolith, and moulded into the finished form. The concrete is allowed to set a requisite length of time, the forms are removed, and the building stands complete—a structure carved, as it were, out of solid rock.

It is thus seen that the erection work con sists primarily of four distinct operations: (1) The erection of the centering or falsework ; (2) The placing of the reinforcing steel; (3) The mixing and placing of the concrete; (4) The removal of the centering.

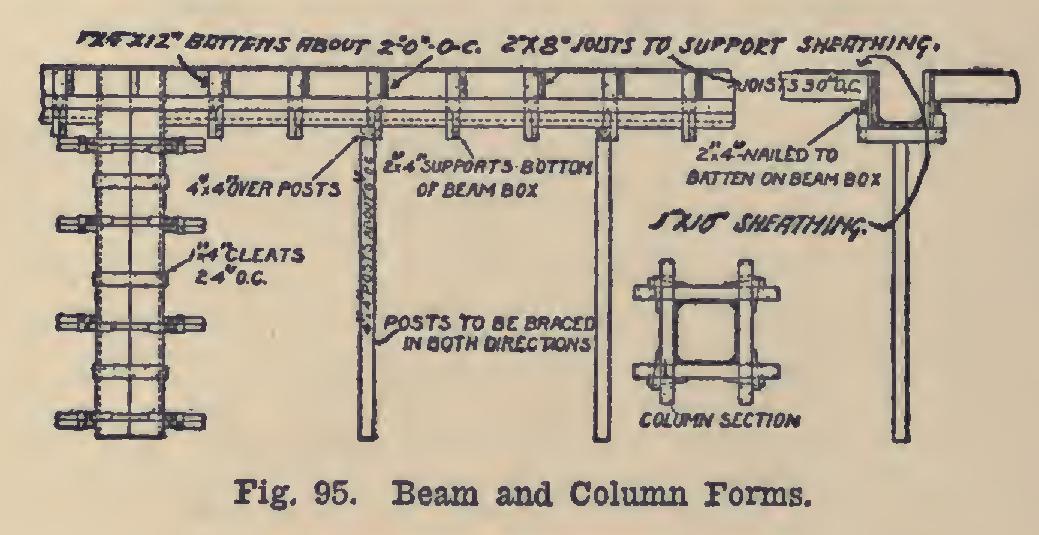

As the forms represent the mould from which the finished structure is made, great care is used to make these exact and true to line. They are built rigid, and thoroughly braced so as to bear the weight of the plastic concrete without de flection. In order to give a smooth finished sur face, planed boards are used, and corners of col umns and beam boxes are chamfered. All joints are set closely together to make the forms fairly water tight. Soft soap or some like preparation should be smeared on the forms to prevent the concrete from sticking.

The steel is set accurately in place in accord ance with detailed drawings prepared for that purpose; and these drawings are followed explicitly.

Only the best materials should be used for the concrete, and these are thoroughly mixed in the proper proportions. A rather wet mixture is used. The concrete is poured into the forms and is laid continuously over the entire floor area. It is placed carefully around the steel work, so as not to disturb the location of the bars and to cover them thoroughly at all points. The

concrete is puddled in the form so as to allow no voids to occur.

The hardening of concrete is not a "drying out" process, as some suppose, but is a chemical action caused by the addition of the water to the cement. The concrete takes its "initial set" in a short time, and therefore should be deposited in place as quickly after mixing as possible.

Concrete work is often carried on in the win ter months, and will freeze if precautions are not taken. The freezing retards the setting of the concrete, and often completely ruins it. It is usually best to remove any concrete known to have been frozen. Simple precautions can be taken to prevent such freezing—such as heating the materials, adding salt to the water (less than a 10 per cent solution), keeping the building heated by charcoal grates, and covering the con crete after being laid with some good insulating material such as cement bags, straw, manure, etc.

After the concrete has thoroughly set and hardened, the forms are carefully taken down. This is done gradually and evenly so as to cause no undue shocks to the concrete work. The length of time necessary to leave the forms in place depends very largely on the atmospheric conditions, the season of the year, the thickness of the concrete work, and the kind of cement used. With the removal of the forms the struc tural portion of the building is complete and ready for use. The concrete, however, will con tinue to grow harder and stronger every day.

Table XIII gives the proper mixtures and degrees of wetness for various forms of work.