Hollow-Wall Concrete Silos

silo, silage, wood, freezing, time, insurance and advantage

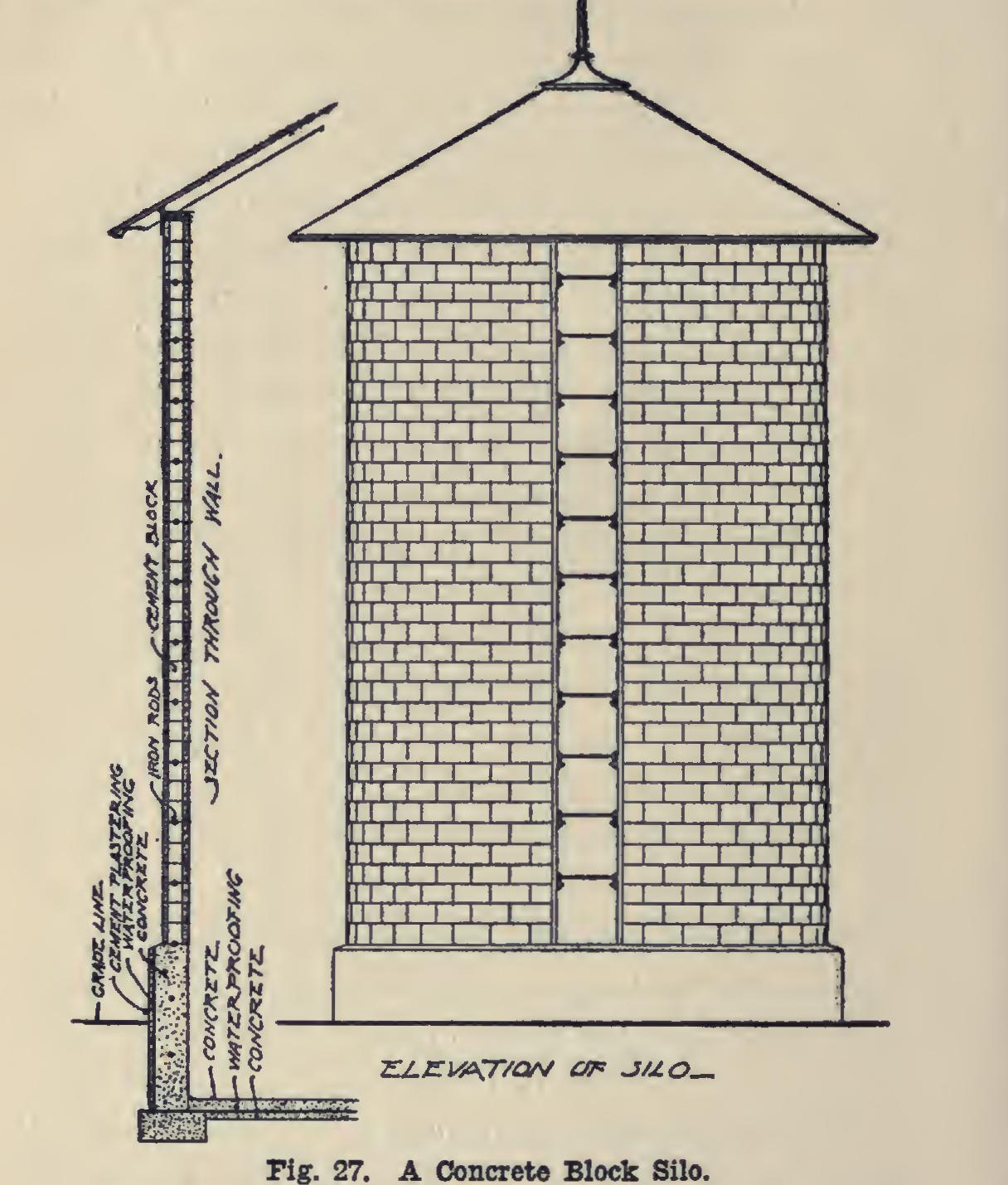

HOLLOW-WALL CONCRETE SILOS Throughout the northern section of the United States and in Canada, the introduction of the hollow wall—continuous dead air space—in concrete silo construction has met with general favor and approval. The advantage of this form of silo is apparent to those living in a country ex posed to very low temperature for prolonged periods of time. With proper attention to the closing of doors, silage can be kept through the coldest winter without freezing. While the question of the use of frozen silage is still being argued by our able State Experimental Stations, it is certain that although freezing may not hurt the silage and may not be injurious to the ani mals that feed on it, it certainly does not add anything of value to the silage. This, in con nection with the trouble of thawing it out before feeding, makes the use of a silo that is proof against freezing, of a decided advantage. Wood silos with double walls have been built through out the Northern States in an attempt to pre vent this freezing; but while they have suc ceeded fairly well in this feature, have in a com paratively short time failed by the rotting of the wood. The silage juices get into the dead air space and rot out the wood in a remarkably short time. Careful ventilation during the warm weather may lengthen the life of the wood for possibly a year or two, but even this ventilation will not prevent rotting for a longer time. The only advantage claimed for the best double-wall wood silo—lined with cement plaster—has been its greater cheapness. With the reduction in cost of the concrete silo, this advantage has now practically disappeared.

This reduction in the cost of the hollow-wall type is due to the use of reinforcement and of specially adapted forms for moulding the green concrete. There are a number of companies operating who build the silo for the farmer, or furnish him with the apparatus or plant to build it himself, with full instructions as to how to build with his own labor. This saves consider able money on the item of labor alone.

Advantages of Concrete Silos. Fire is the farmer's greatest dread. When a fire starts from lightning or any other cause, the farm buildings usually burn down. For this reason, insurance

rates are very high, and farmers find it a great tax to protect themselves by carrying insurance. The buildings, however, are not the most serious loss; fires most frequently occur during the lat ter part of the summer or in the early fall, after the crops have been harvested; and, although the buildings can be replaced, practically the year's work of the farmer is gone. Very often the fire spreads so rapidly that the stock is also lost.

A concrete silo cannot burn down, as concrete is fireproof; nor can the food stored in it be either injured or destroyed. A temporary structure can be erected to replace the burned building, but the crops cannot be replaced, except at great expense.

Insurance companies have recognized the indestructible qualities of concrete by making an insurance rate so low as to be within the means of every farmer.

The only objection that has ever been made to a concrete silo is its cost. The cost varies, owing to the price of materials of which the con crete is made. In many places concrete silos are cheaper than any other kind; few farmers are without a gravel pit suitable to furnish both gravel and sand of a quality proper for making good concrete. Moreover, Portland cement can now be obtained at a reasonable cost. Under these conditions, a concrete silo is cheaper than any other kind.

The best is the cheapest, regardless of the original cost. A silo which never leaks, will not blow over, is always ready to be filled with out first repairing, requires no repairs, cannot burn down, and is vermin-proof, is certainly the best and cheapest. A concrete silo is all of these.