Moulds for Ornaments

mould, sand and composition

MOULDS FOR ORNAMENTS In making artificial marble in moulds, we de part from the dry tamp process, unless iron moulds are used; but where only one or two pieces of each design are required, the cost of special iron moulds would bar their use.

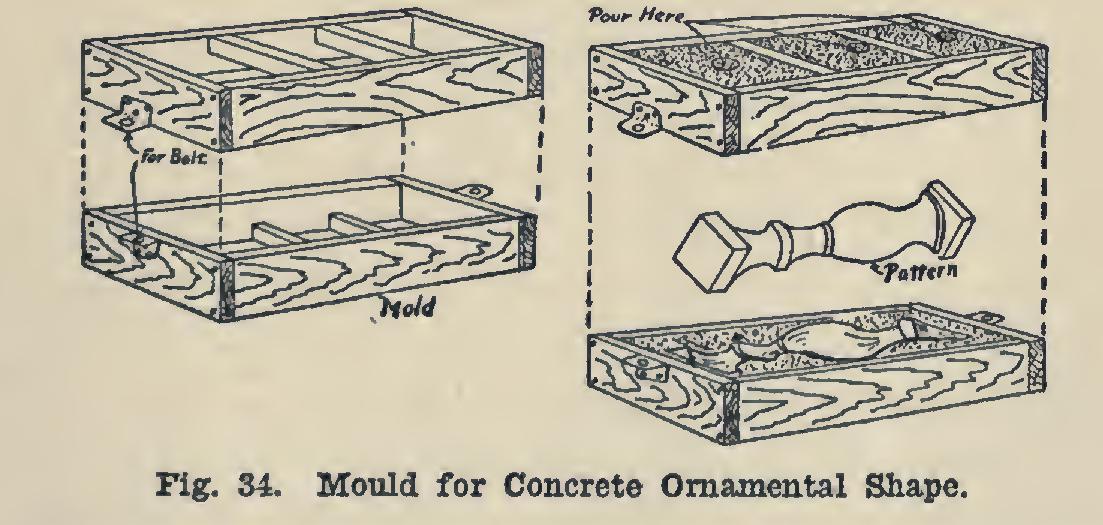

However, should any iron moulds that meet the requirements be on the market, their use is preferable to that of wooden moulds. The latter may be made and used as follows: Make a wood pattern exactly like the article desired, and a flask for it as shown, and, in fact, the same as is done in any cast-iron foundry. Fill the mould in the same way, only that one pound of plaster of Paris to every 12 pounds of sand is used. This composition is dampened and rammed into the mould. After it has been care fully filled and the wood pattern removed, let it stand for a day, then coat the interior with a heavy lather (lacquer) to insure a smooth finish. Close the mould, and fill with a composition con sisting of one part Portland cement, one part marble dust, and two parts fine sharp sand, all to be mixed with sufficient water to admit pour ing, keeping the composition agitated until poured. Do not open the mould until the ce

ment has set at least twenty-four hours; then keep it damp for five or six days. To polish, let the cast dry for a week or ten days more, when brisk rubbing with dry felt, adding dampened oxalic acid occasionally, will produce a luster equal to that of any natural marble.

Openings for pouring must be made at all high places; and, before removing the pattern, it is well to penetrate the moulding sand with a steel wire, thus allowing a free escape of the air, thereby preventing honeycombs. See Fig. 34A.

Some experience is necessary to make this process a success, and by careful usage the same mould can be used several times. Crushed lime will produce whiter but less durable work. stone may be substituted for the sand, which Almost any color can be produced by adding the coloring to the composition in the dry state. This process of making casts is adaptable to all man ner of round spindles for stairs and porches.