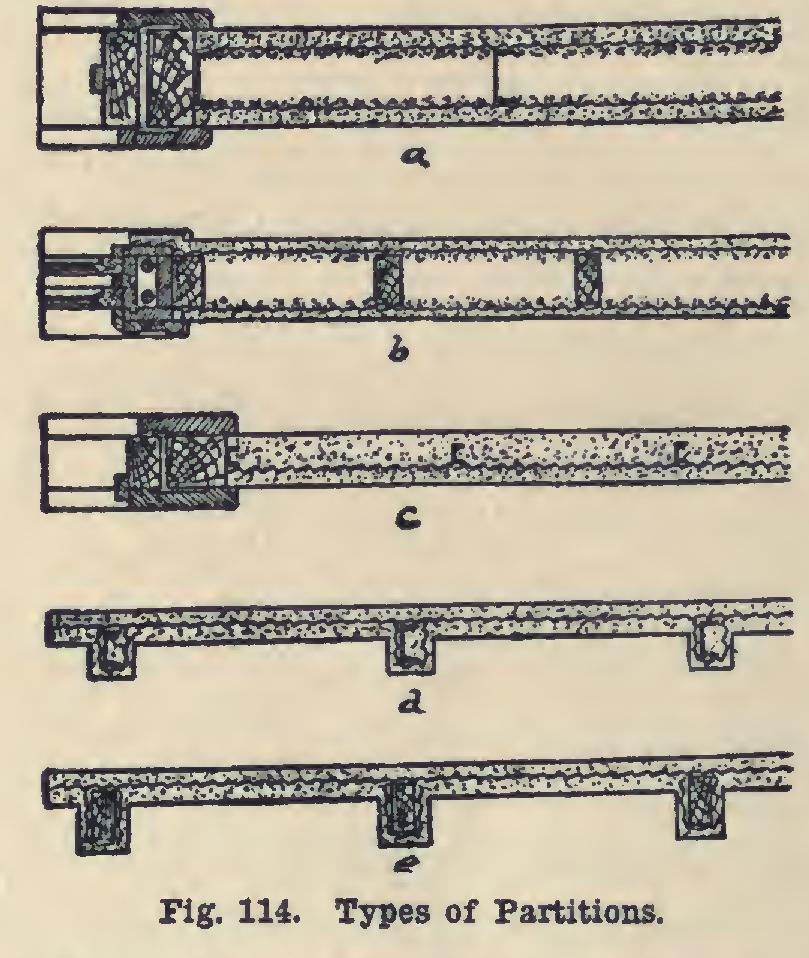

Partitions

metal, solid and inches

PARTITIONS Partitions in reinforced concrete construc tion work consist of both solid and hollow types. In factory work, partitions may be made of rein forced concrete four inches thick, of tile, or of concrete blocks. For solid partition walls and elevator wells, it is convenient to pour the con crete after the floors are laid. This may be done by leaving a slot in the floor at the proposed location for the partition.

In the plant of the Bush Terminal Company in South Brooklyn, N. Y., the reinforcement in their solid parti tions around the elevator and stair wells consisted of %-inch round rods spaced 15 inches apart both horizon tally and vertically.

In the Lynn Storage Warehouse, at Lynn, Mass., around the elevators and stairs, and also to enclose the offices on the first floor and storage rooms on the fifth floor, expanded metal partitions were employed. Ex panded metal lathing, No. 24 gauge, was wired to 1-inch channel bars placed vertically 12 inches on centers, and the lathing then plastered with five coats so as to form a solid partition 2 inches thick.

The first or scratch coat consisted of one part cement to 3 parts of lime, with the usual quantity of sand and hair. This pressed through the lathing, so that it could be

plastered on both sides with a brown coat of lime and cement mortar in proportions 1 part cement to 3 parts of lime mortar, and followed by a finishing coat of the same mortar on both sides.

Solid partitions

are built up with two face forms supported against a rigid framework of uprights. In the middle of the space between the face forms, the reinforcing agent is held firmly in place for the concrete. Such partitions run from 3 to 6 inches in thickness, depending upon the location and class of building. Only light aggregates should be used in this class of work.

Hollow partitions

are studded, and metal lathing of some form is held by metal fastenings on each side of the studding. A heavy coat of mortar is then plastered on each side of the metal wall thus formed.

If expanded metal is used as a reinforcing agent in partitions, always lay the metal with