Reinforced Concrete Walls

wall, slab, fabric and building

REINFORCED CONCRETE WALLS Walls for buildings may be of various types, largely depending upon the style of structure and the use to which the building is to be put. In the monolithic form of reinforced concrete building, the space between the outside beams, girders, and columns on the ends and sides may be filled in with a curtain wall of brick, tile, or even a reinforced concrete slab with bars run ning two ways for strength and to prevent shrinkage. In residence work, walls are some times built double, with a 4-inch air-space be tween the two reinforced slabs. In this type of wall, the reinforcing rods should also run hori zontally and vertically.

The thickness of slab and amount of rein forcement necessary for a curtain wall, or a vertical wall which is to bear no weight, is de termined by figuring it as a flat slab supported at all four sides, and carrying a uniformly dis tributed load of 40 lbs. per square foot due to wind pressure. An ordinary slab designed on this basis will probably be four or five inches thick, allowing for a good factor of safety.

In

small structures, it is common practice to build the walls as one continuous reinforced piece, hollow or solid as desired, the forms being carried up as the wall progresses. The rein forcemeat in such walls consists of lateral rods, wires, expanded metal, or wire fabric, as thought best in the individual case. Window- and doorframes should be thoroughly reinforced to pre vent the formation of cracks from one to another.

Metal ties used in hollow walls should have their surfaces covered with cement to prevent corrosion and gradual wasting away. At the corners of the building, the reinforcing rods or material used, from the two sides, should lap over each other so as to make a firm corner joint and tie the two walls together. This applies to both double and solid walls.

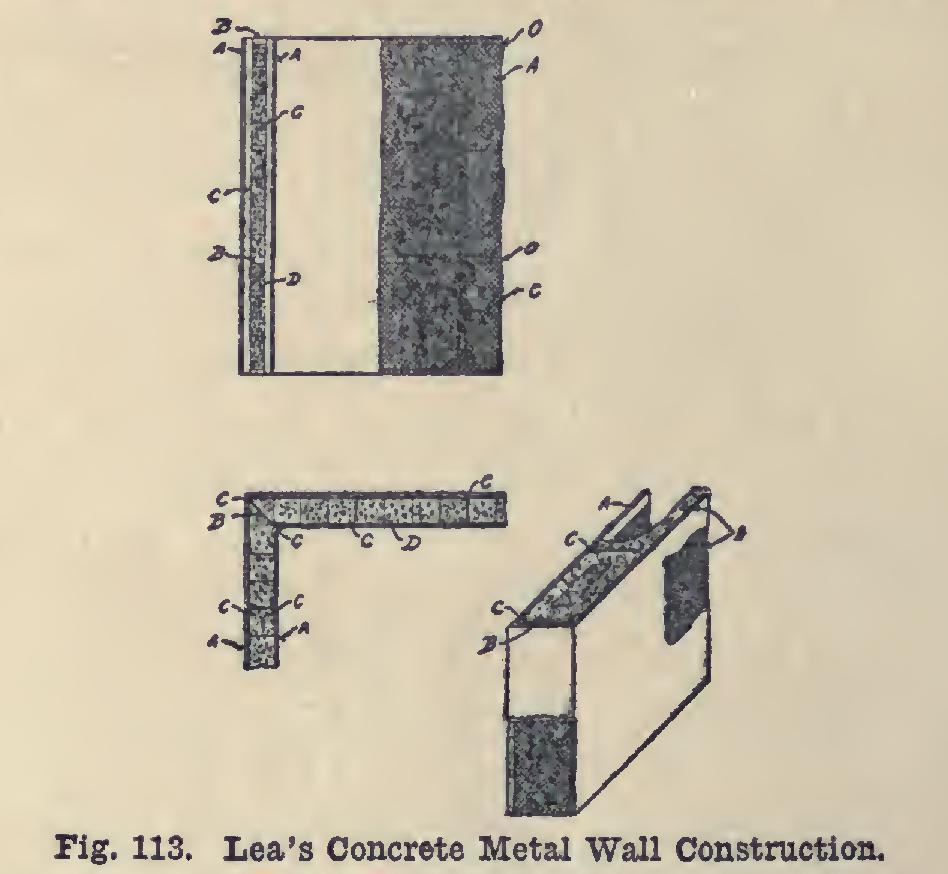

Fig. 113 shows a form of wall construction known as Lea's Concrete Metal Wall. In the figure, .

A=Wire Fabric. B=Spacing Bar. C=Vertical Member. D=Separator.

O=Horizontal Member.

A frame of the desired form is erected of structural steel and covered with wire fabric as shown. A coating of cement or mortar is then applied to the outside of the wire fabric which, upon hardening, forms a shell of the desired out line, which may be filled in with concrete. This method of construction does not require the use of forms or moulds, thus effecting a great sav ing in material and labor, besides affording a strong, well-finished structure. It may be em ployed in building dams, retaining walls, culverts and other structures.