Reinforcing Materials and Systems

steel, concrete, rods, bars, close, placed, rust, differential and bottom

"The best carbon steel for structural purposes is found to possess an ultimate strength between 55,000 and 65,000 lbs. per sq. in. The elastic limit of the steel should be not less than one-half of the ultimate strength, and the stretch in a measured length of 8 inches should be not less than 24 per cent. It should stand the cold and quench-bend test, 180 degrees flat, without fracture. In the quench-bend test steel is heated to a cherry red, as seen in the dark, and quenched in water at ordinary temperature, before bending.

"The proper use of steel in concrete is in small sec tions well distributed throughout the mass. The bars should be separated from each other to give the gripping effect of the concrete full play. If they are placed in a layer close together, a cleavage joint is formed, and the concrete is liable to break off. This would be the case in a close coil or set of rings close together or in a set of rods lying close together near the bottom of a beam. Plates or sheets of steel should not be used as separators or spacers for rods, as these will also form cleavage planes. If heavy rods are used, surrounded by comparatively little concrete, the concrete is unable to grip the steel, and the differential expansion due to change in temperature will crack the concrete. Pyramids of concrete surrounding the bases of outdoor steel col umns seldom last through a winter without being cracked. Girders covered with a shell of concrete would be subject to the same detrimental effect of differential expansion.

"The steel should not be placed close to the surface of the concrete. It cannot be gripped properly unless it is deep enough in the concrete for the latter to take hold. It cannot be protected from rust and fire unless there is some concrete between the steel and these destroying elements. It is bad practice to lay the steel on the forms, and then the concrete on this. The steel is neither prop erly protected nor gripped by such means. The depth to which steel should be buried depends upon the size of the section. It is manifest that the heavier the sec tion, the more concrete is needed to grip it and to over come differential expansion. If rods are bedded deeper they will be less affected by external change of tem perature. Heavy rods are of more importance in a structure, hence their protection is of more vital impor tance than that of light rods.

"Standard sizes of rods or shapes should be used as much as possible, so that they can be obtained without delay from the mills. Also, as few different sizes as possible should be employed. Simple details are essen tial. A complex structure will be difficult to surround properly with concrete. There should be no broad, flat surfaces to work the concrete under.

"The steel work should be designed with a view of its being easily placed in proper position, and held there against the displacing tendencies due to the placing of the concrete. Where rods cross, they should be wired

together, and this should be done before the forms are erected to the point that they will interfere by prevent ing free access to the rods. Extra wires may often be used to advantage, to tie the rods in place. These wires may serve the further purpose of holding the sides of the forms from spreading. They can be cut off at the sur face when the forms are removed.

"Rods in the bottom of a slab can be kept from lying on the bottom of the form by placing small stones under them just before the concrete is placed." Bars for reinforcing may be bent or twisted either at the work or at the manufacturing plant. Twisted bars can be readily obtained from the manufacturers; but in cases of large contracts, the twisting is often done at the place of installation. The number of twists per inear foot depends upon the diameter of the bar; thus, for bars, there may be five twists per foot; and for 1-inah bars, one twist per foot. In computing the cross-sectional area of steel in reinforced concrete, the twisted bars are figured as square bars of the dimension before twisting.

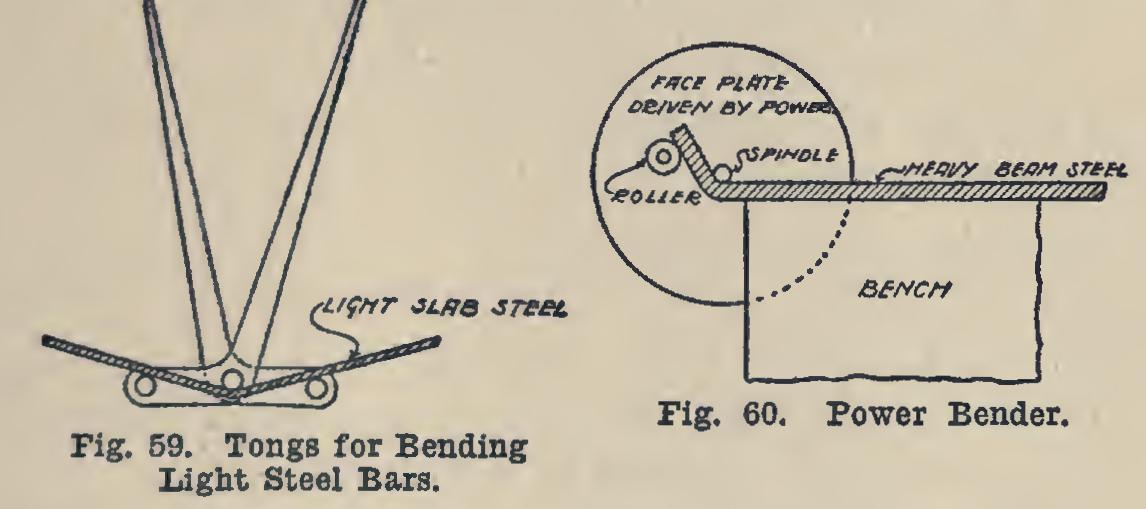

Fig. 59 shows a pair of tongs which may be used in bending light steel bars during the con struction work. Fig. 60 shows a power bender used for the heavier shapes. Light bars may be bent cold. In the case of heavier bars which are heated and then bent, care should be taken to see that the steel is properly annealed after wards, to restore its original properties.

Life of Steel in Concrete.

Good concrete is one of the best known preservatives of steel. The mixture should be wet when the steel is embedded, and thoroughly tamped so as to coat the steel completely. Dry or porous mixtures allow access to the steel of air or other vapors, which should be avoided. It is generally as sumed that steel embedded in concrete does not corrode. Instances where steel has stood in con crete for years seem to prove this. In fact, it has been stated that steel with a slight coating of rust, when placed in position, has been found to be bright when removed after considerable lapse of time. An exception might be made to the above statements in case of injury to the concrete causing cracks, since rust or corrosion is liable to occur at these cracks.

An objection has been made to the possible corrosion of steel embedded in cinder concrete through the action of sulphur in the cinders; the case, and that the corrosion resulted mainly but experiment seems to show that such is not from the rust, or iron oxide, in the cinders. Cinder concrete should be especially well rammed while)Net.