A Modern Apartment House

smoke, shed, concrete, inches, ducts, roof, floor, inside and observatory

"The steel framework of the smoke ducts and the main rafters where they pass through the smoke ducts are encased in concrete. This concrete casing is rein forced with expanded metal. At the ends of the shed, and at cornices along the two sides of the shed, all metal work is encased in concrete. The sides of the ducts are high enough to prevent driving rain or snow from reach ing the platforms. The longitudinal glitters mentioned above are drained by leader pipes running down inside every other supporting column, where they connect with drains under the platforms. The air-space between the inside of the columns and the outside of the drain-pipes insulates them from freezing, and the drain-pipes are not exposed, adding to the appearance of the shed and elim inating possible damage to drain-pipes from baggage trucks. The electric lights are arranged in longitudinal lines between the columns. Arc-lights were installed for temporary use only. In daytime, ample light reaches the interior through the skylights and the smoke ducts.

"The main advantages of these sheds are: first, the original cost is much less, being about 40 per cent less than the cost of a high-roofed shed in the case of a large terminal; second, cost of maintenance is very much less ; third, there is more light; and, fourth, there is no smoke or gas inside the shed, and much less noise. One of the large items of saving is in maintenance cost of painting. The steel work is never exposed to engine gases and smoke. At the smoke ducts, where it would be in con tact with these gases, it is protected by concrete. In the walls of the duct immediately under roof-slab are small flues which allow any gases which might get behind the smoke duct, or any heated air rising from the platform level, to escape to the duct and thence to the open air. When paint is required, high scaffolding is not needed, which means a further saving. Aside from material, there is a saving in the first cost of the shed because of the ease of erection. Everything can be handled by derrick cars, doing away with falsework, and the work is easily carried on without interference with traffic or inconvenience to the public.

"There arc skylights on each side of the smoke ducts, admitting light directly to the windows of the cars on the track below. The frame of the skylight is a small channel, on which, at intervals of 18 to 20 in., are fastened malleable iron bridges or stirrups. These support flat iron bars with elongated holes engaging brass studs screwed into the stirrups. The glass plates rest on sheet metal guides, strips of cow-hair felt being laid between the glass and the guides as cushions, while on top of the glass are corresponding strips of felt, held in place by sheet-metal guides. No putty or cement is used. Three-eighth-inch glass is used. In the Hoboken shed, similar to this, sheets of glass 27 in. by 86 in. were used.

In the Scranton shed, the sizes were cut down to 20 in.

by 60 in., which is now believed to be the best size for skylight work.

"The roof of the Bush shed is accessible for painting, cleaning, or removal of snow. If snow is removed from the roof, it may conveniently be shoveled through the smoke ducts into gondola cars beneath." An Observatory. There has recently been completed on the top of Blue Hill, a few miles from Boston, a reinforced concrete observatory which presents some interesting features aside from its stability. One of the essential elements required in the design was absolute resistance to the entrance of water under the conditions of heavy, beating rains at very high velocities.

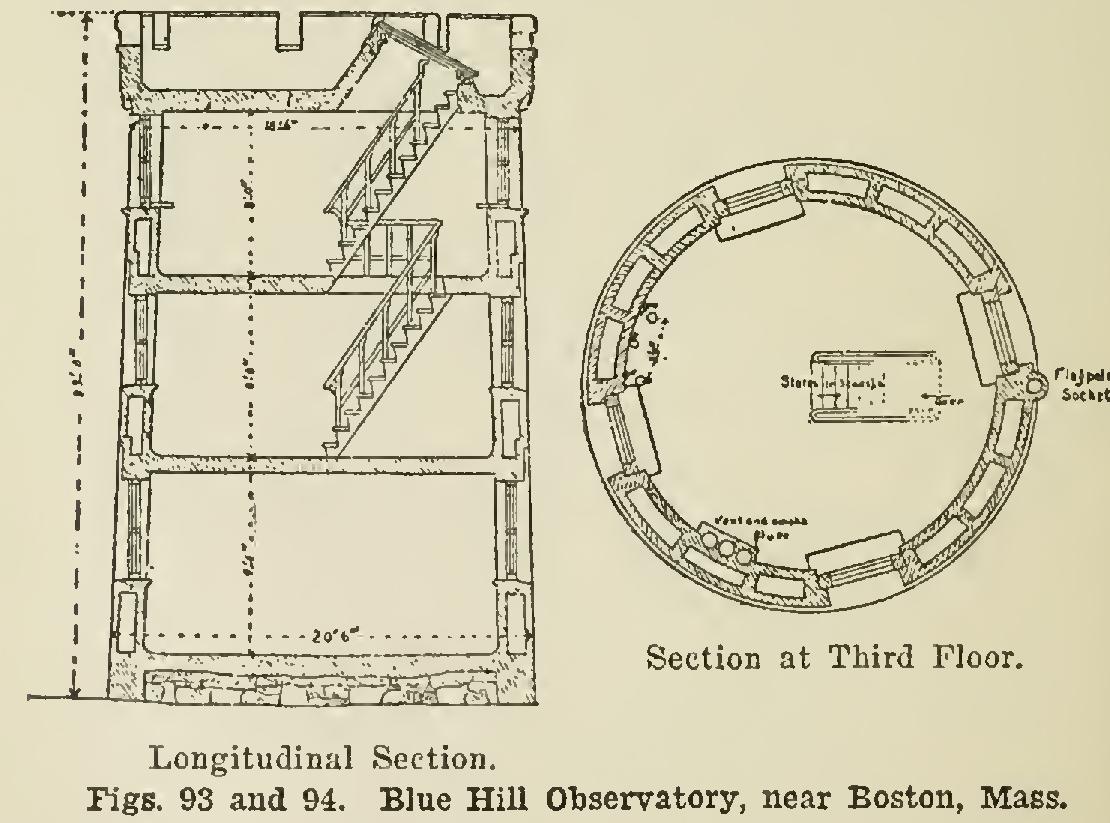

The observatory is of circular section, 17 feet 6 inches inside diameter, 20 feet 6 inches on the outside, and 33 feet high (Figs. 93 and 94). The walls are of double thickness of 4 inches each, separated by a 10-inch air space, which provides an absolute means of preventing the passage of water.

Reinforced concrete was selected on account of its many advantages, important among these being its un yielding stability, freedom from vibration in high winds, and its water-tight qualities, so necessary in a location where wind velocities range up to 80 and even 100 miles per hour. Expectations have been so fully realized that the action of the self-recording instruments has been entirely free from the unknown errors which were caused by the rocking of the old observatory, and there have been no signs whatever of leakage.

The observatory is built on a ledge, the walls being bonded thereto; the floor is slightly raised to provide an air-space beneath. A separate 4-inch granolithic finish was put on top of the first floor to provide a smooth tread, as well as to prevent any possible access of mois ture. The general concrete mixture was 1:2:4.

Steel reinforcement consists of 1/4-inch square twisted bars, spaced nine inches on centers, running in directions at right angles to each other, embedded in the concrete near the surface and extending into the wall.

The second and third floors and the roof are 6 inches thick, reinforced with square twisted rods at right angles to each other and projecting into the wall. Those for the second floor vary in spacing from 12 inches on centers at the circumference to 5 inches apart at the center. Steel reinforcement for the third floor and roof is practically identical with that of the second floor, but with an added number of bars on each side and at the middle end of the stair openings and roof scuttle. The reinforcing bars are placed close to the bottom of the floors, while those for preventing cracks close to the wall are placed near the top, being bent up at the wall and hooked over the nearest inside horizontal wall-bar. All floors, including the roof, are granolithie finish.