Miscellaneous Uses of Reinforced Concrete

tie, ties, block, rail, track and wide

It is needless to say that such accidents cannot hap pen where cement ties are used.

Another form of reinforced concrete tie is known as the Core11. This tie (Plate 30) con sists of two reinforced concrete blocks about 28 inches long, 12 inches wide, and 10 inches thick, held in place by a steel tie-bar embedded in the blocks in slots in their top surface, and attached to the rails by bolts which hold clips to the rail flanges. The ties are said to sustain high-speed traffic in first-class shape, to hold the track in alignment and gauge, and to show no ill effects from frost. It is claimed that they are inde structible; that they make a remarkably strong, firm foundation for the rails; that they do away with center-bound track; that they take the wheel load on central pressure; that a 12-inch contact with the ballast directly under the rails affords a much better support than is afforded by the ordinary 8-inch tie. Another claim is that these ties can be made at the nearest gravel-pit, thus saving heavy freight charges—always a large item in the cost of wooden ties.

On the question of cost, which, of course, is always a most important factor, it is said that these ties can be installed, either in new con struction or to replace rotten ties, as cheaply per mile as standard white oak. The ties being 12 inches wide, it takes only two-thirds as many as of 8-inch ties, and, when once in place, they never have to be renewed.

The ties are made in hydraulic pressure ma chines, and are uniform in size, furnishing a much smoother and more even track than is pos sible with ties varying little and big; and it is claimed that this does away with swaying side motion on high speed. It is further claimed that the double-sleeper tie, as the Corell tie is some times called, admits of the solid ballasting of the center of the track, holding it in line and pre venting it from shifting sideways; and the bolt ing of the rail to the ties avoids "creeping rail;" and the tie-bar arbitrarily holds the rails in gauge.

A type of reinforced tie known as the MacMartin is used by the Delaware & Hudson Railroad.

This tie makes use of wooden cushion blocks embedded in the concrete upon which the rail rests. There are two of these wood blocks under each rail—the upper one, covering the entire width of the tie, called the "wearing block;" the under one, the "inset block," which allows the spike to be driven as at present. This lower block, 4 inches wide, is embedded in the concrete, and remains permanently in the tie, while the wearing block may be readily slipped out and renewed. This top block is held securely in place by means of a steel plate bent in the shape of a Z-bar, the lower end of which acts as an anchor holding it in the concrete, while the upper end presses down on the block. The blocks are wide enough to allow a Weber insulated joint to be spiked in the same manner as at present on a wood tie. This joint is probably as wide on the base as anything used.

This tie preserves the method of spiking now in use, and also allows the track to be gauged and shimmed as at present. The latter feature is a very important one in northern latitudes, and in this type of tie, shims may be easily placed under the rail during winter and spring. The staples in the ends of the tie are very convenient in handling.

The Madden and Simpson concrete tie is the type now being used by the Chicago, Milwaukee & St. Paul Railway Company. It has been in use on the main track of the La Crosse division for several years and has been found very satisfactory.

This tie also makes use of a wood block em bedded in the concrete, thus allowing the rail to be spiked in the same manner as at present. The block is 3 in. by S in., and is covered with a steel band which goes all around the tie. Holes are punched in this band so that the spikes may be driven into the wood block beneath it. The band thus serves as a tie-plate.

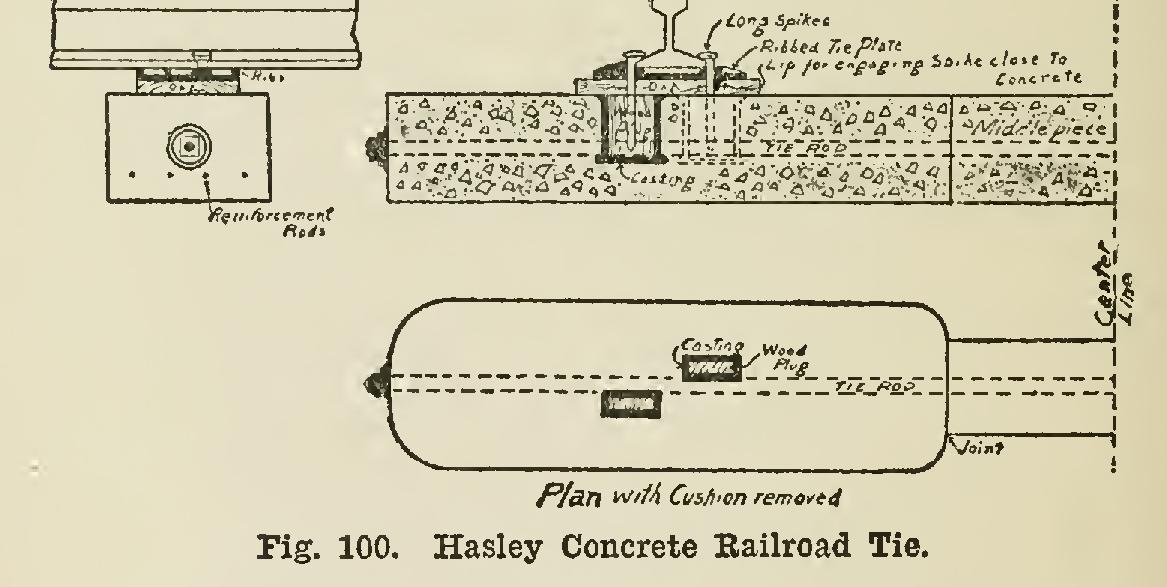

The Hasley tie, which Fig. 100 illustrates, has the unique feature of being made in three parts, thus facilitating handling.