Miscellaneous Uses of Reinforced Concrete

inches, rods, shaft, sections, reinforcing, placed and feet

"Concrete can be shaped to exact curves and dimen sions. This is impossible with brickwork.

"A reinforced concrete sewer can be built, as a rule, more cheaply than a brick or masonry one, and the con struction is more rapid.

"A reinforced concrete conduit or sewer can be de signed to withstand bursting pressure due to a hydraulic head.

"Concrete sewers, even of large size, can be moulded in advance and laid in sections when this method of ,construction is desirable or economical.

"Concrete sewers are usually built in place; pressure pipes and small sewers—say those under three feet in diameter—are often laid in sections which have been moulded in advance. This latter method of construction is economical on account of the thin sections of concrete that may be used, accurate forms and 'shop methods' permitting the adoption of thinner sections than could be constructed in place." For cuts of sewer construction, see frontis piece and Plates 22 and 23.

Fig. 98 shows the method of reinforcing a small conduit with sheet or wire fabric.

Concrete Shaft Lining. In Plate 24 is shown an interesting piece of reinforced concrete con struction. The conditions under which the work was done, and the excessive loading on the con crete, were far above the normal.

In sinking a shaft through limestone rock for the Detroit Salt Company, the contractors ex perienced considerable difficulty from small streams of water coming under a high head through small fissures into the shaft. After vainly endeavoring to stop these leaks in various ways, it was decided to use a reinforced lining for the purpose.

The first section of lining was placed in a section of the shaft about 250 feet from the surface. It was 2 feet in thickness, and was reinforced with 1-inch Gabriel complete trussed rods, placed 4 inches on centers, top rods being placed on the same centers. In order to shorten the span the shaft was divided by struts into three sections. These struts, owing to the necessity for economy of space, were made of structural steel I-beams, great care being taken to get as near a perfect bearing as possible at the ends. In lower portions of the shaft,

where pressure is higher, the reinforcing rods were placed 2 inches on centers, and the slab thickness was from 27 to 30 inches. In these lower sections a hydraulic pres sure of about 30,000 lbs. per sq. ft. was successfully resisted with no measurable deflection—a feat that seems almost incredible.

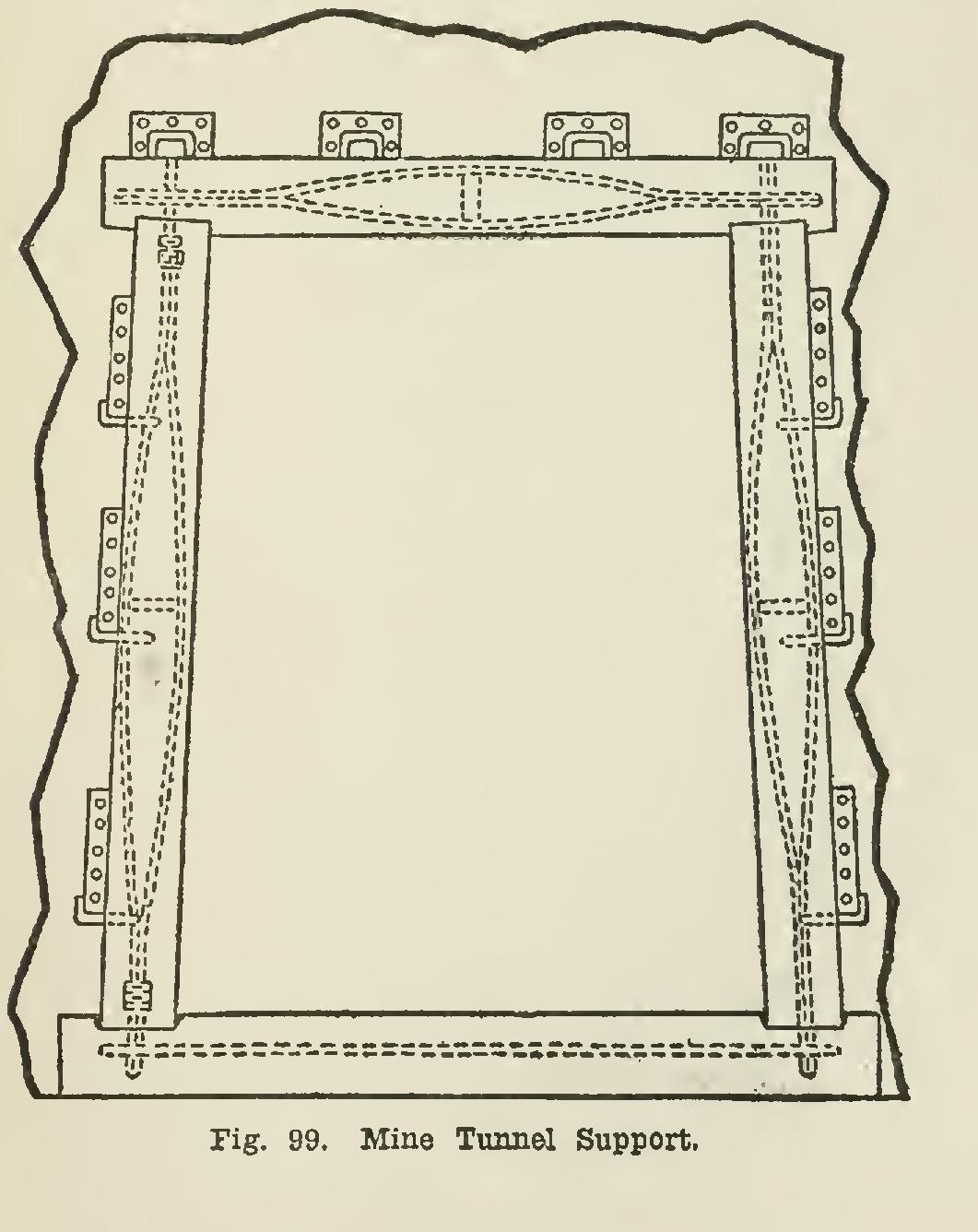

Mine Tunnel Support. A cement mine sup port, claimed to be impervious to fire, water, and wear, has been devised by a Colorado. in ventor.

Instead of the rough-hewn timbers cut from the mountain side, adjacent to the property, a support said to be superior and costing much less is offered in the concrete article. The support ing frames and cross-piece have been brought to such a stage that the breaking strength has been increased to a point many times beyond that of the strongest mine timber of triple the size. The reinforcing rods are made in the form of a simple truss, and so placed that the pressure will be directed against the apex. These rods are not, necessarily, large in section, as the surrounding body of concrete supports them against the lateral bending. See Fig. 99.

The inventor claims that the cost of construc tion is from 10 to 15 per cent less than that of the ordinary timbers, when the latter are easily available. For an ordinary drift it sets feet by 6 feet; the posts are made 4 inches by 5 inches in size; and the caps are 4 inches by 7 inches. In these, a reinforcing loop, made of iron rod, is embedded. In the posts the rod extends above the upper end sufficiently to pass through a hole in each end of the cap. Nuts are screwed on the ends of these rods to hold the cap in place.

The invention provides strength against lat eral pressure for the members of the supports, this being the vexing question; for while rein forcement by the use of straight rods would meet requirements in ordinary construction, in this case it was necessary to devise some method by which the lateral strength of the beam could be increased, while at the same time the reinforcing member would be confined to a narrow space.