Factory Plumbing

water, iron, fig, feet, sewer, floor and tank

FACTORY PLUMBING This is a branch of plumbing to which too little attention has heretofore been paid, and is a very profitable field if gone after properly. A trip through a number of factories will, in the majority of cases, reveal almost anything but sanitary conditions—with all due respect to the manufacturers. If the manufacturer would consider for a moment the fact that if he should provide clean accommodations for his em ployees, there would be a tendency on their part to greater neatness in work; there would also certainly be a saving in time over the present system, under which employees have in some cases to go a considerable distance to find toilet accommodations. The subject of toilet-rooms is well worth the consideration of any manufac turer, from any point he cares to look at it.

Fig. 90 shows a floor-plan of a model toilet room. The number of fixtures may be increased or decreased to suit the conditions. The build ing may be constructed of either brick or wood. The figure shows a room 20 feet wide, 30 feet long, and 14 feet in height, built of brick; with a cement floor; the side walls cemented 6 feet from the floor; and all woodwork painted with a good grade of waterproof paint. This allows the attendant to wash the entire room thor oughly at night, with a section of hose, thus putting the room in a thoroughly clean condi tion for the next day's use. The floor slopes to a deep floor-drain, which allows the water to escape rapidly, but which retains all dirt. By lifting the strainer, this dirt may be easily removed.

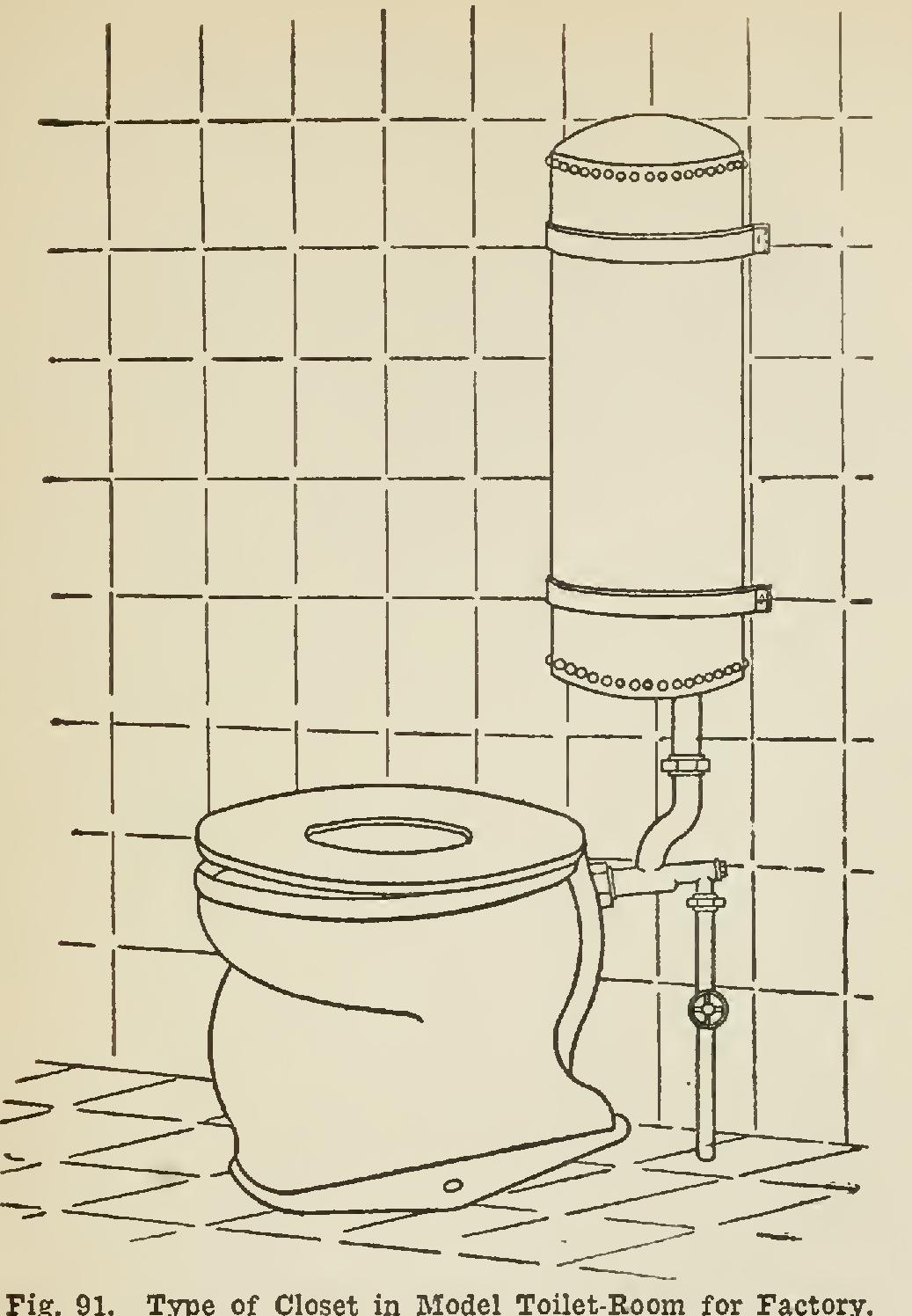

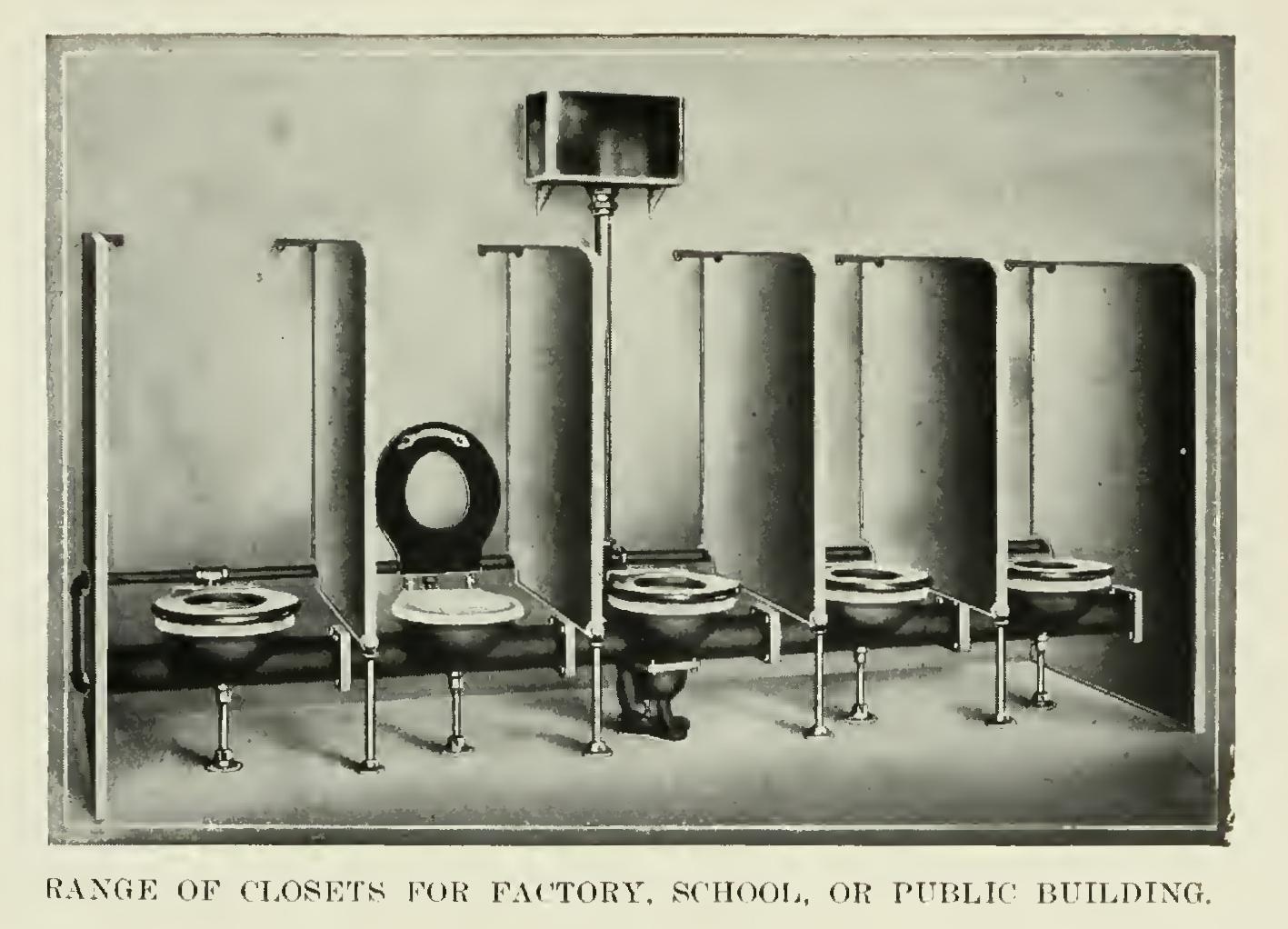

The wash sinks are 10 feet in length, made of cast iron, enameled inside, and resting on iron standards. The waste has a standing plug which allows about 5 inches of water to stand in the sink if desired; or, by removing the plug, the water may run away at once. The hot and cold water is supplied through compression faucets, the number of which may be increased or decreased as desired. Individual wash stands may be installed if desired, and this is a matter for the owner to decide. The closets are seat-operating; that is, the tank fills when the closet is in use, and flushes when the seat is vacated. Fig. 91 is an illustration of the

closets.

Each closet has a cut-off valve in the supply pipe to the tank, so that, in case of repairs to the flush-valve, the water need not be shut off the balance of the fixtures. The closets are cast iron, enameled; and the tanks are of galvanized iron. The closet stalls, and also the urinal stalls, are made of cast iron; and the doors of the closet stalls are made of wood. The urinals are of the flat-back type, cast-iron, enameled, and are flushed from an automatic flush-tank. Fig. 92 shows a front elevation of the urinals. Each urinal is separately trapped.

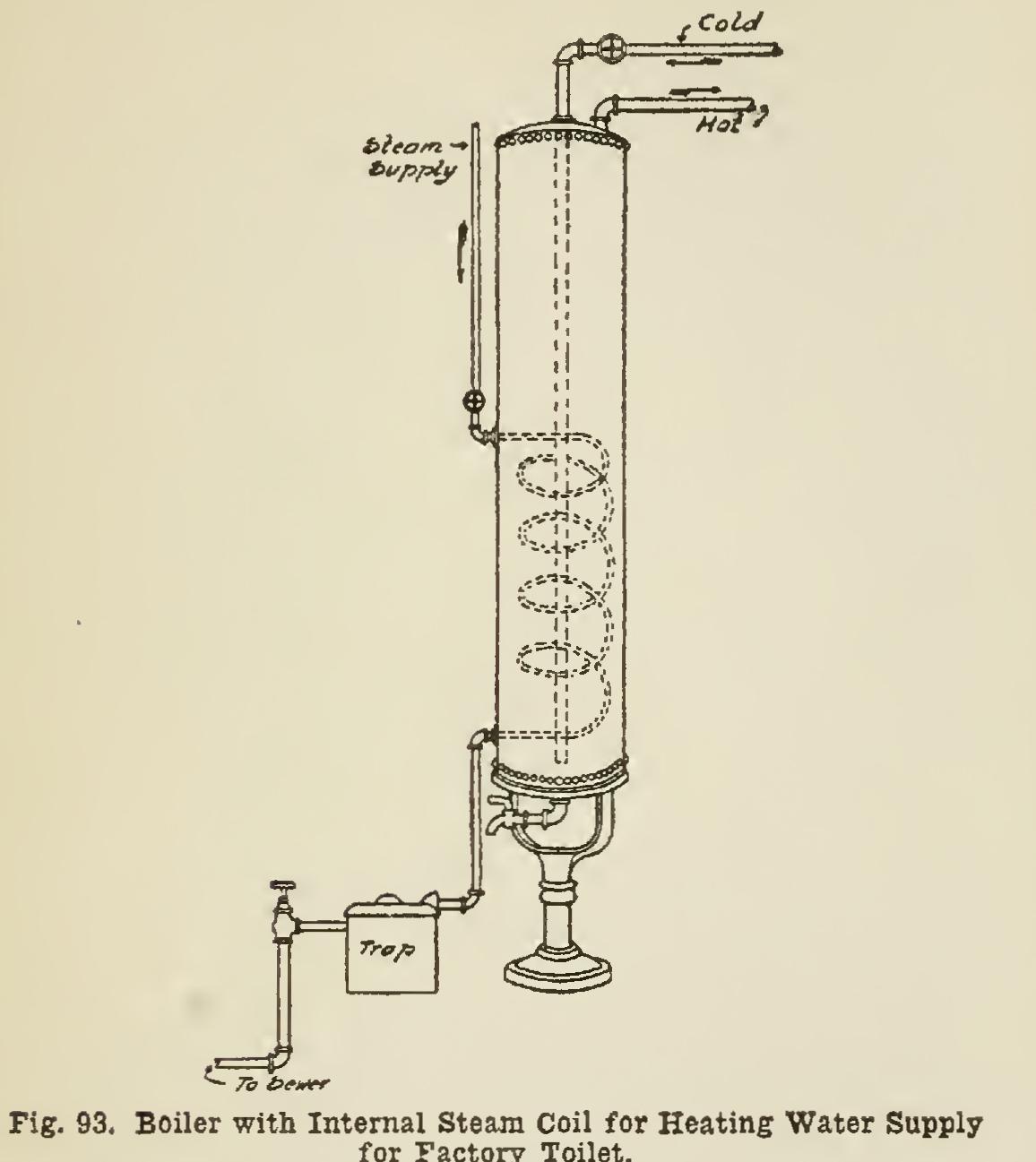

The hot water is supplied from a 120-gallon, galvanized range boiler, with a steam coil inside, as per Fig. 93; and the condensation is trapped to a blow-off tank in the yard, before going to the sewer. The object of the blow-off tank is to cool the condehsation before allowing it to enter the sewer. Steam should never be connected directly to any sewer, as it soon causes the sewer pipe to deteriorate, and will start the joints to expand, where they are leaded joints, thus damaging the sewer.

The proper sized steam coil to use for this boiler, with steam at different gauge pressures, can be determined from tables already given.

The main soil-pipe may be trapped or not, where it enters the building; and local rulings usually cover this point. From a careful study of the soil- and waste-pipes shown in Fig. 90, it will be seen that the siphoning of any of the fix tures is not very apt to occur. Clean-out plugs are placed at points which give free access to the entire drainage system without disturbing any floor, in case of a stoppage. This is a point which should be considered in all plumbing installations.

In Fig. 92 it will be noticed that the city water is connected to the end of the urinal waste-pipe. This allows for the thorough flush ing of this pipe in case of a stoppage.

A ventilator placed in the roof will carry away any odors from the room.

The water piping is of galvanized iron, of the sizes shown.

Provision must be made for heating and lighting the room during the winter season.