Heating Accessories

steam, pressure, boiler, water, valve and fig

HEATING ACCESSORIES A detailed description of all the various types of accessories or minor appliances used on heating work would require more space than is here available, and we shall therefore illus trate and describe only those which are neces sary to the completion and to the perfect working of the ordinary steam or hot-water heating apparatus.

Steam Boiler Trimmings. There are cer tain appliances which should always be placed on a boiler used for heating purposes. One of the most important of these is the water column and gauge, Fig. 86, for registering the height of water in the boiler. As a further safeguard in this respect, try-cocks or gauge-cocks are placed on this water column in order to prove the height of water should the glass from any cause he broken.

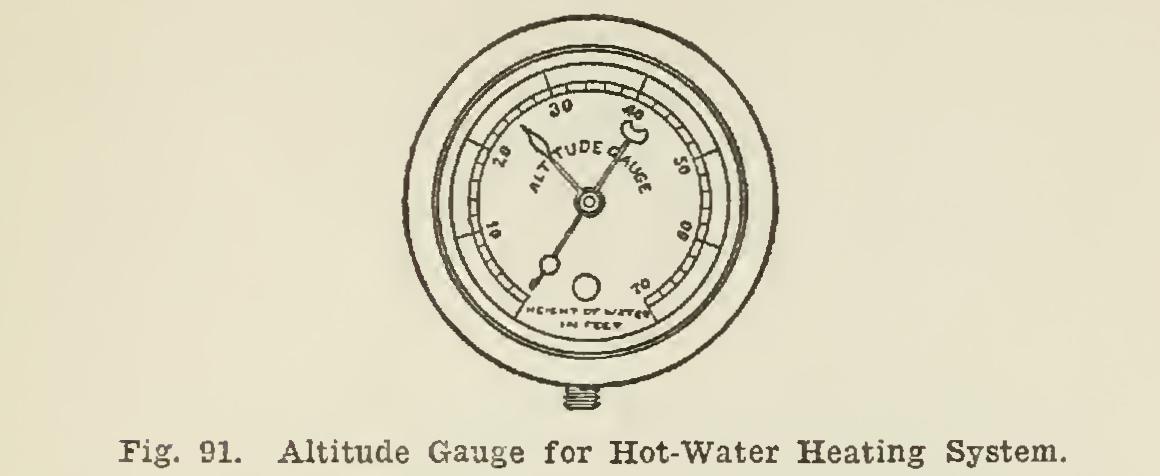

A steam gauge, Fig. 87, should be attached to every steam boiler. The gauges used are ordi narily of the Bourdon type, and consist of a hol low tube bent into circular form. One end is attached to an opening in the bottom of the gauge to which the steam supply is connected.

The free end of the tube is attached by gearing to a pin operating the hand or pointer, which moves across the dial shown on the face of the gauge as the pressure on the interior tube straightens it, by this action indicating the pressure carried in pounds.

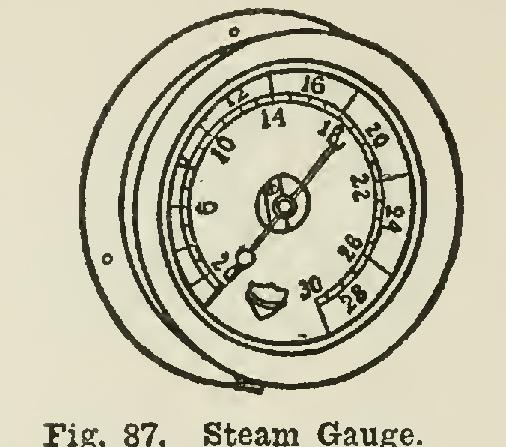

A steam boiler should invariably be fitted with an automatic damper-regulator, which opens or closes its draught doors according to pressure of steam on the boiler. This attach ment may be so set as to cause the draught door to remain closed and the check door open, or so that a certain pressure of steam will operate both doors automatically. In the construction of this regulator, usually two castings in form resembling an old-fashioned soup plate are bolted together, with a rubber diaphragm be tween. The pot thus formed is connected to the boiler in such a manner that the dia phragm receives the pressure of steam against its lower side, raising its center against a plun ger inserted through an opening in the top casting or half of the pot. A rod bolted to this

plunger is also attached to a lip on the outer edge of the upper casting, thereby forming a lever which operates the draught and check doors by chains connected to them from the ends of the rod. A sliding weight placed on this lever rod may be moved to regulate the pressure at which the device will operate. Fig. 88 shows the conunou form of this automatic damper regulator.

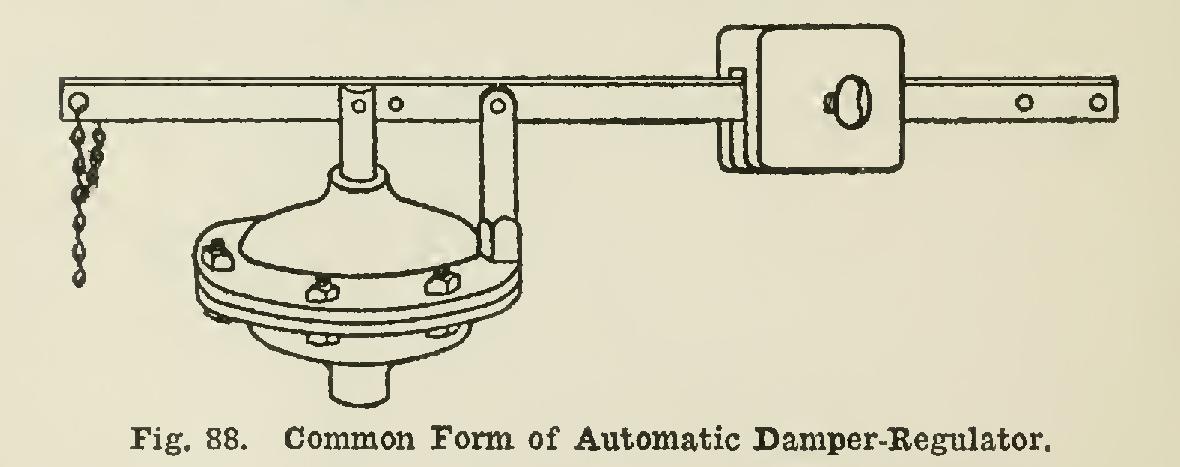

As a matter of safety, and to provide against possible danger or damage to the boiler from the generation of an excessive pressure, all steam boilers should be fitted with a proper safety-valve. Such valves are all practically built on the same principle, consisting of a valve seated in such a manner as to open outward, the disc being held in place by a weight or spring. There are three varieties in common use—the lever safety-valve; the spring or pop safety-valve; and the weighted valve, the latter consisting usually of an ordinary style of valve with disc and seat, the disc being held in place against the pressure of steam by a ball weight mounted on top of the stem, the balls provided being of various weights according to the pres sure it is desired to carry. The spring "pop" valve, Fig. 89, is the type used on low-pressure heating boilers to a greater extent than any other variety.

Each of the three types of safety-valve per forms the same function. When the pressure of steam on the apparatus increases beyond the point at which the weight or spring of the valve will overcome its force, the disc is, automatically raised from the valve-seat, and the excess of steam is thereby allowed to escape to the atmos phere, after which the weight or spring again closes the valve.

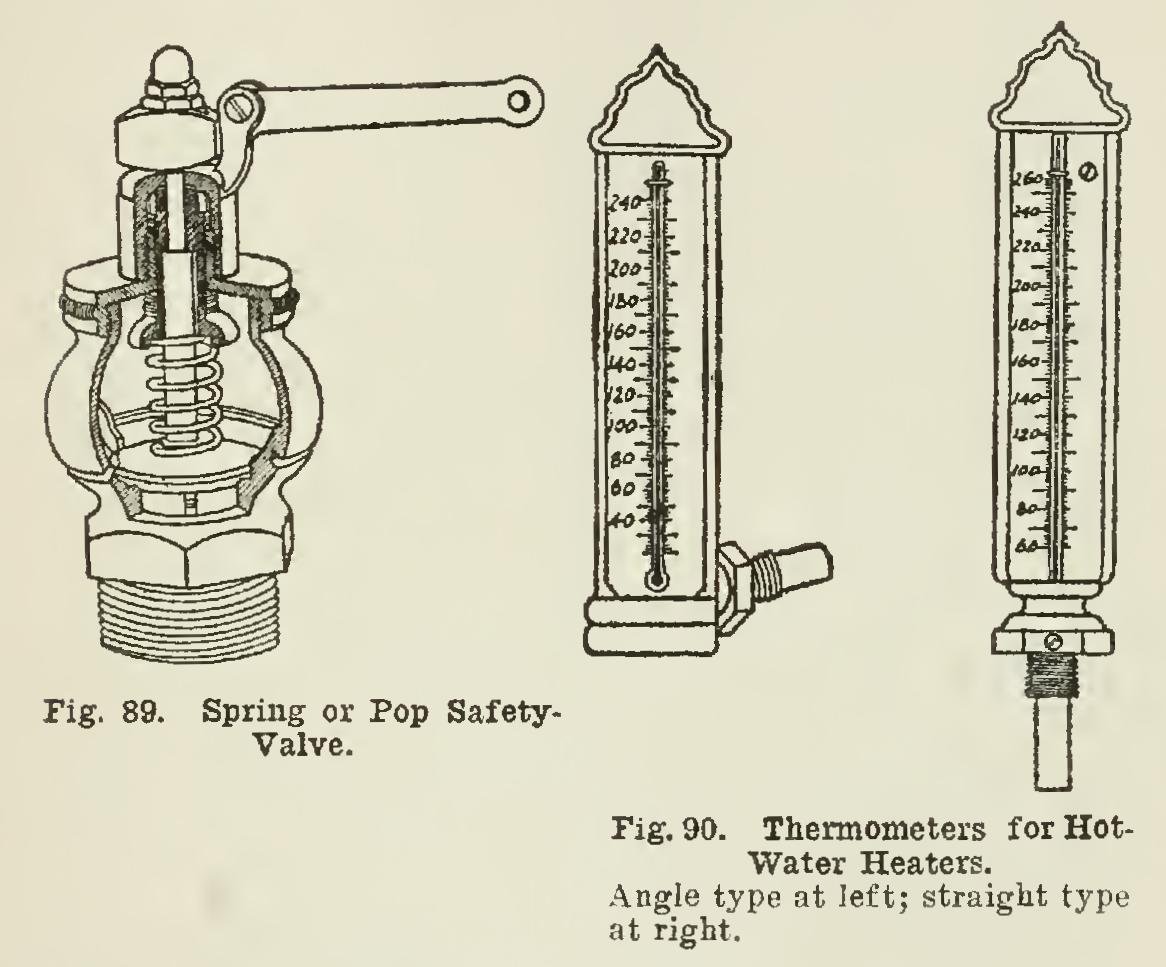

Hot-water heaters are provided with a special form of thermometer, as shown in Fig. 90, for indicating the temperature of the water in the heating system, and also with an altitude gauge, Fig. 91, which indicates at the heater the height of the water in the sytem.