Hydraulic Rams

water, ram, fall, pipe, drive-pipe, gallons, distance, valve, efficiency and supply

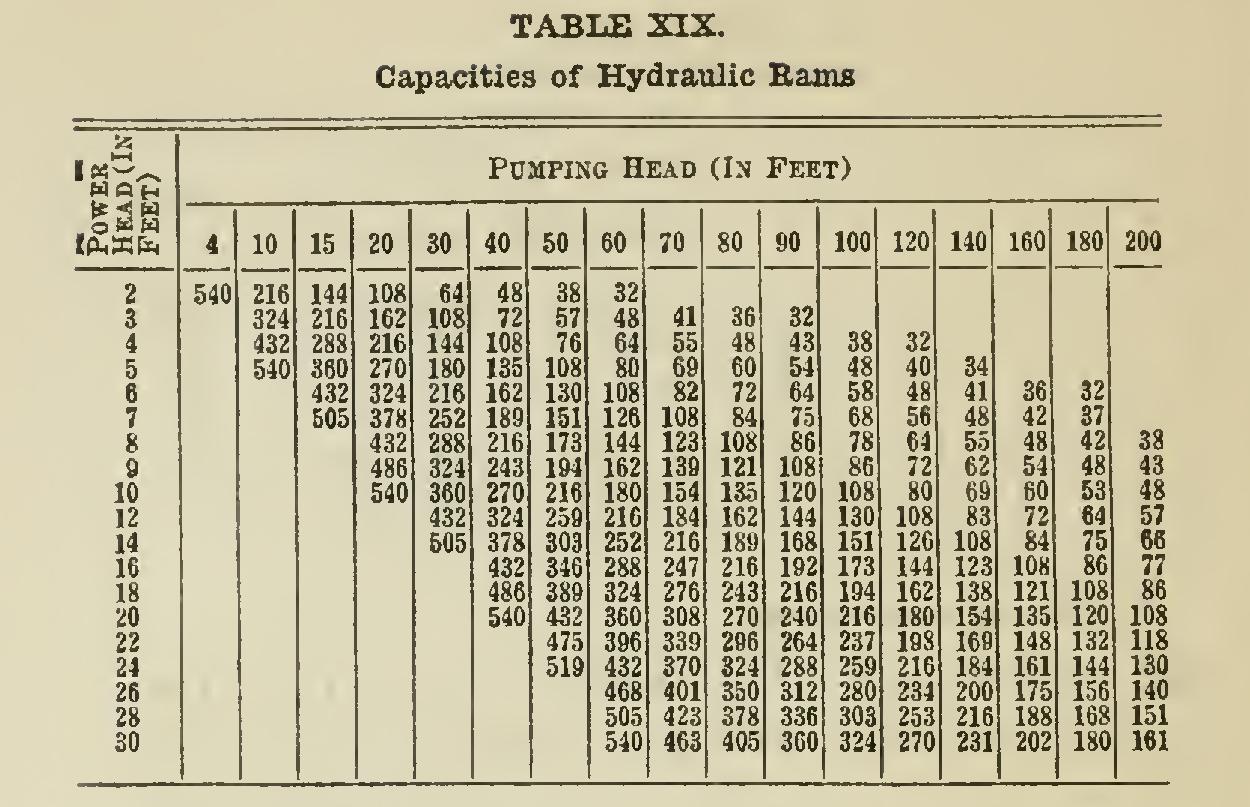

The question of efficiency of hydraulic rams has been much discussed, and such authorities as Rankine and D'Aubisson differ considerably in their calculations. The tables in this article are based on Rankine's formula in calculating efficiency, which is: qh (Q-q) in which Q is the quantity of water flowing per second in the drive-pipe; q, the quantity flowing per second to the standpipe through the dis charge pipe; H, the height from the escape valve to the level of the reservoir which feeds the drive-pipe; and h, the difference in the level of the water-supply reservoir and the water in the standpipe.

D 'Aubisson states the formula for efficiency as: D 'Aubisson's formula is the correct one, con sidering the mechanism as a machine receiving energy at one end and delivering it at the other; while if the machine is considered as elevating water only from one reservoir to the other, Ran kine's formula is the correct one to use.

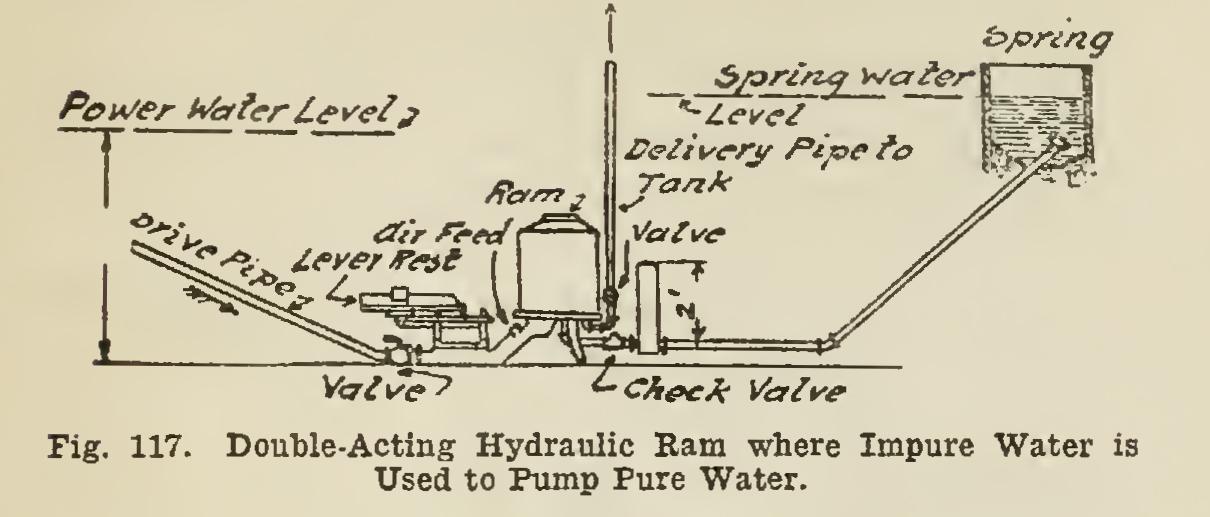

The double-acting rams may be used to ele vate pure water to a tank, using impure water for the driving water.

Directions for Making Surveys for Hydraulic Rams. In order to determine the proper-sized ram to be used for any installation, it is neces sary to make a careful survey to obtain the fol lowing information: (1) Flow of water per minute in gallons.

(2) Vertical fall in feet.

(3) Distance in which fall is obtained.

(4) Vertical height above ram water is to be ele vated.

(5) Distance water is to be raised.

(6) How many gallons required per day.

(7) If a double-acting ram is required, flow in gal Ions, of the spring water per minute; and the fall, in feet, from the spring to the ram.

(1) Determine this by the time necessary to fill a vessel of known capacity from the source of supply.

(2) Find the difference between the level of the surface of the water in the source of sup ply and the lowest point within a reasonable distance.

(3) State this difference.

(4) Find the difference between the level of the proposed location of the ram and the highest point to which the water is to be delivered.

(5) Find the length of pipe necessary to conduct the water from the ram to point of delivery.

Length of Drive-Pipe.

To insure sufficient air being fed automatically at each stroke, it is imperative that the drive-pipe should be of the proper length, which is determined by the fall to the ram, and the height to which water is delivered. In order to obtain the desired fall, it is frequently necessary to convey the water a greater distance than the length of the drive pipe used.

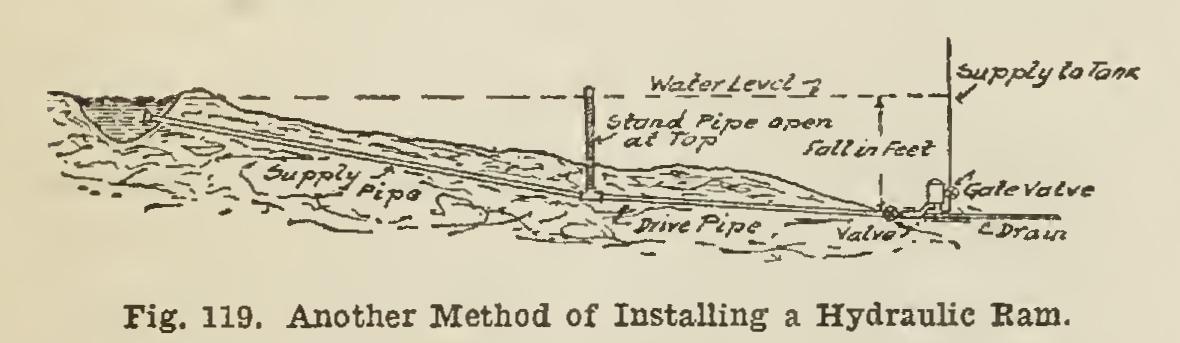

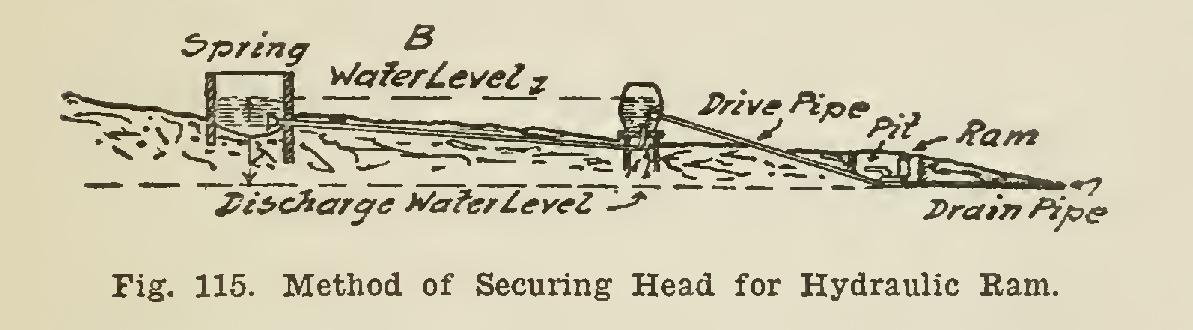

Fig. 115 illustrates a method of securing the necessary head or fall.

(a) Locate the ram the proper distance from the spring or water supply, and connect as shown at A.

(b) Conduct the water to an intermediate reservoir (barrel, box, or standpipe) located the proper distance from the ram, connected as shown at B.

(c) Sink the ram in a pit to necessary depth and lay a drain pipe from pit to a lower point, as shown at C.

Double-Acting Rams—Directions for Set ting. The ram should be on a level, firm foun dation. It need not be fastened down. The drive-pipe must be set on a perfectly straight incline, without bends or curves, except where the pipe enters the ram, and this should be done by bending the pipe. The upper end of the drive-pipe should be sufficiently below the sur face of the water, so that it cannot suck air— say one foot or more. All drive-pipes should

have a good open strainer on upper end. Be sure that the drive-pipe is air-tight. Use a opening gate valve laid on side.

The delivery pipe can be laid with the neces sary bends, according to the usual practice iu water pipes. Connect all pipes before starting the ram, and leave them uncovered until it is shown that there are no leaks. Use gate valves on delivery pipe.

Start the ram by forcing the escape valve open by hand; allow it to close, and repeat the operation until enough water has been forced into the delivery pipe to create a back-pressure, and cause the ram to work automatically.

At the start, put the slide weight over the center• of the balance rod, and fasten securely. By raising and lowering the leather-covered rest under the balance valve lever, by means of the two nuts thereon, the opening of the valve can be lessened or increased, which will lessen or in crease the amount of water used and delivered by the ram. The greater number of strokes, the less water is used and pumped. The fewer strokes, the more water used and pumped.

Under each condition, the ram runs best at a certain opening of this valve, and this can be determined only by experiment.

By changing the nuts on the lever rest, the position will be found where the ram runs with an easy, even stroke; then it is in proper working order.

The air-feed should be open at all times suf ficiently to allow a small spray of water to escape at each stroke, thus insuring a constant supply of air, which prevents water-logging. The open ing in the brass air-valve must "look down." The length of drive-pipe is most important, and is governed by the ratio of the fall to the elevation. If too long or too short, the auto matic supply of air is interfered with, and the efficiency impaired.

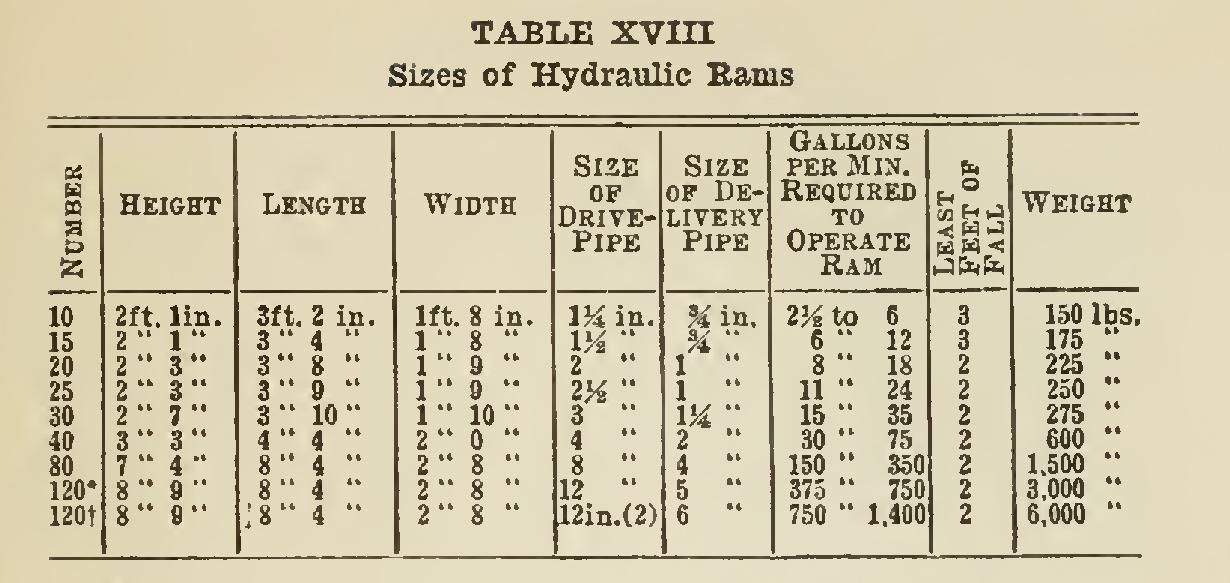

By using batteries of rams, unlimited amount * Single.

t Duplex or double acting.

can be delivered. This is often done for fire pro tection purposes, and for supplying the water for small towns or villages, or large institutions.

The efficiency developed is governed by the ratio of fall to pumping head, and varies from sixty to ninety per cent.

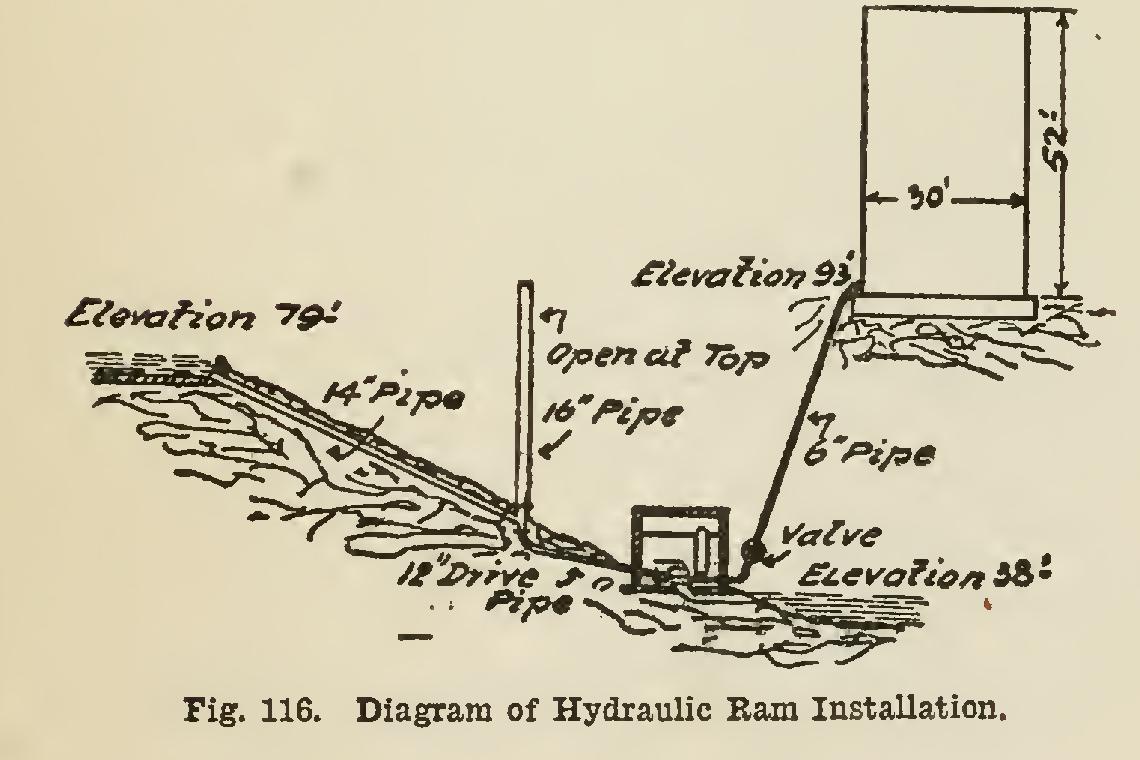

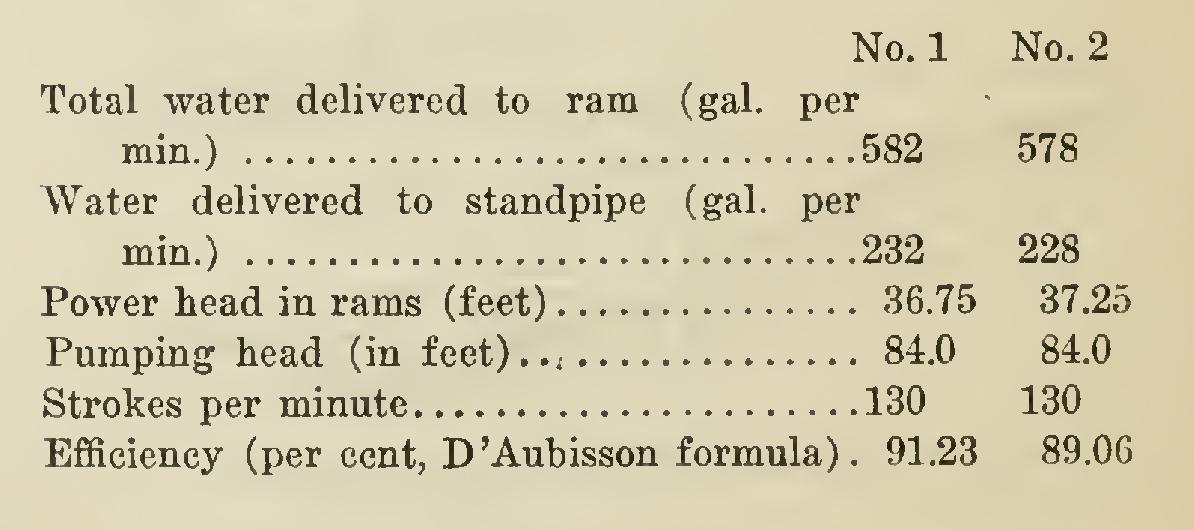

In the hydraulic ram installation at the U. S. Naval Coaling Station at Bradford, R. I. (see Example—With a supply of 1,400 gallons per minute, 10 feet fall, 50 feet elevation, a No. 120 Rain will deliver 302,400 gallons per day, 1,400x216=302,400. Multiply factor opposite "Power Head" and under "Pumping Head" by the number of gallons per minute used by the ram (see Table XVIII), and the result will be the num ber of gallons delivered per day.

Fig. 116), the efficiency guaranteed in the con tract was seventy per cent, but the tests showed mean results in excess of this, as follows: These rains could have used 750 gallons per minute each ; 532 gallons was all that was available when tests were made.

Fig. 117 illustrates the working of a double acting ram, where impure water is used to pump pure water.

Figs. 118 and 119 illustrate methods of installing rams. A careful study of this article will enable anyone to install these useful ma chines, and will open up a profitable field for the plumber in country work.