Pipe and Boiler Insulation

covering, asbestos, heat, surfaces, loss and heated

PIPE AND BOILER INSULATION The thorough insulation or covering of all piping on a steam or hot-water heating ap paratus, as well as the covering of all exterior surfaces on the boiler or heater not occupied by the various pieces of plate-work (the clean-out, fire, and draught doors, the frames, jacketing, etc.), is essential to the economical operation of the apparatus. Tests have conclusively proven that the insulation of such surfaces effects a saving of from fifteen to thirty per cent, the amount depending upon the character of the covering applied.

To be of good quality, the insulation must consist of such material as will prevent the escape of heat outwardly between the pipe and the surrounding atmosphere. As a matter of fact, heat may be lost or dissipated from the hot surfaces of the pipe or heater in three ways— namely, by radiation, by conduction, and by convection. The effects of these, however, can be partially or entirely overcome by the covering.

The materials which have been most gener ally used for the purpose of insulation are as bestos, hair felt, mineral wool, cork, magnesia, pressed paper, and sawdust. Pipe covering as furnished to-day is manufactured in three-foot lengths, split lengthwise for ease of adjustment on the job, and covered with muslin or canvas pasted over the cut. It is fastened securely in place by iron or brass lacquered bands, Fig. 117 illustrating the method.

For high pressures and superior work, a moulded covering composed of about 85 per cent magnesia, with the remainder of fiber asbestos and similar fireproofing materials, is generally adopted.

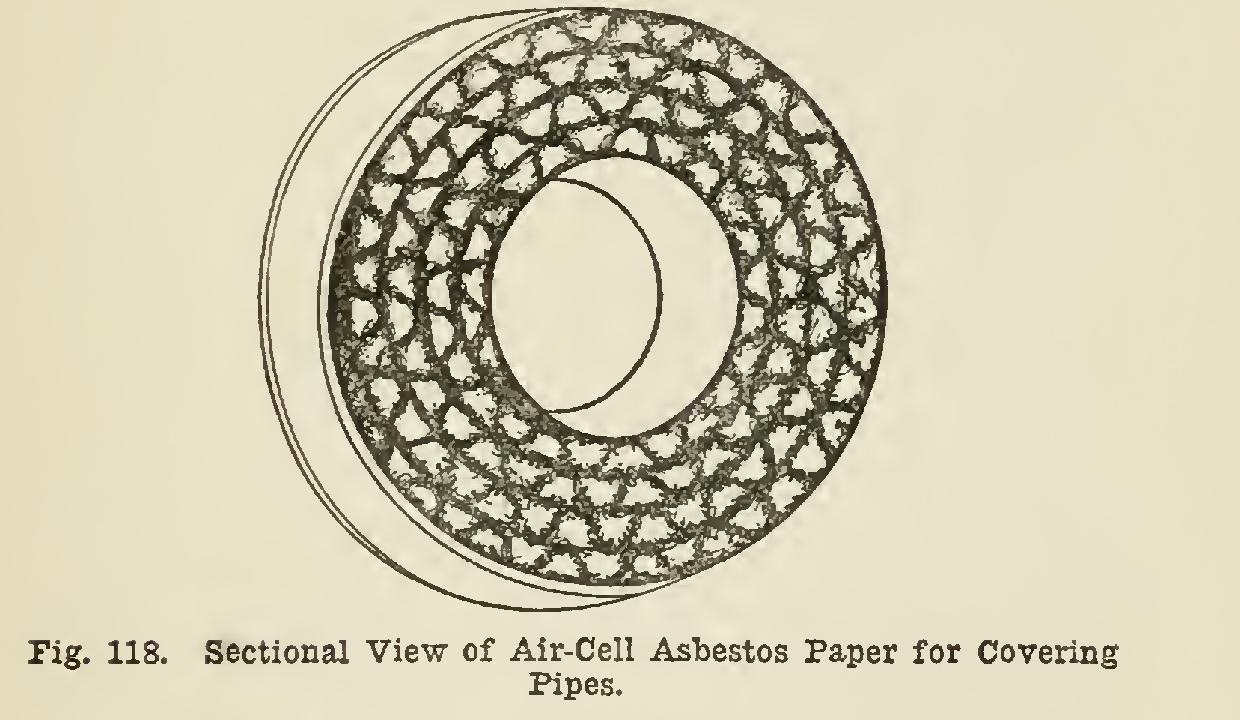

For ordinary low-pressure heating and for hot-water work, a less expensive covering may be employed to insure satisfactory results. On such jobs, several layers of felt paper lined with asbestos, or strips of corrugated asbestos, or a covering made of ground cork, can be em ployed to advantage. Felt or asbestos paper specially wound to form air cells running lengthwise with the piping, affords a practical covering. Fig. 118 shows a cross-section of this

type.

To obstruct the passage of radiant heat pre sents no difficult problem, and almost any non conducting substance will suffice to accomplish the purpose. To prevent loss by convection and conduction is, however, a different proposition.

The heat from the steam or water is imparted to the inner surfaces of the pipe by contact; and iron being an excellent conductor, the heat is quickly transmitted to the outer surface, and it is at this part of the pipe that the great loss occurs. The heated pipe in this respect acts in exactly the same manner as a radiator or coil placed in a cold room. The air immediately sur rounding the pipe is heated by contact, and rises above the pipe by reason of its lower specific gravity. The cold air replacing it is in turn heated, too, this process of radiation of heat continuing as long as there is any hot water or steam in the pipe, when in an uncov ered condition. It is to prevent this great and continual loss that all piping should be thor oughly covered. To be of effective service in overcoming this loss, the covering must fit snugly against the pipe.

Hair felt, asbestos (which is a natural, fibrous rock, whose fibers have been separated and broken up), magnesia, and cork have a low thermal conductivity, for this reason being more efficient for insulating purposes than other materials.

It is customary to protect boiler or heater surfaces with a lagging consisting of a plastic covering composed largely of asbestos and mag nesia in the form of a cement, which is plastered upon the exterior portions to be covered, while they are hot. This method of application aures a hard and firm covering when dry.