Radiating Surfaces

air, radiator, pipe, casing, coils, iron and stack

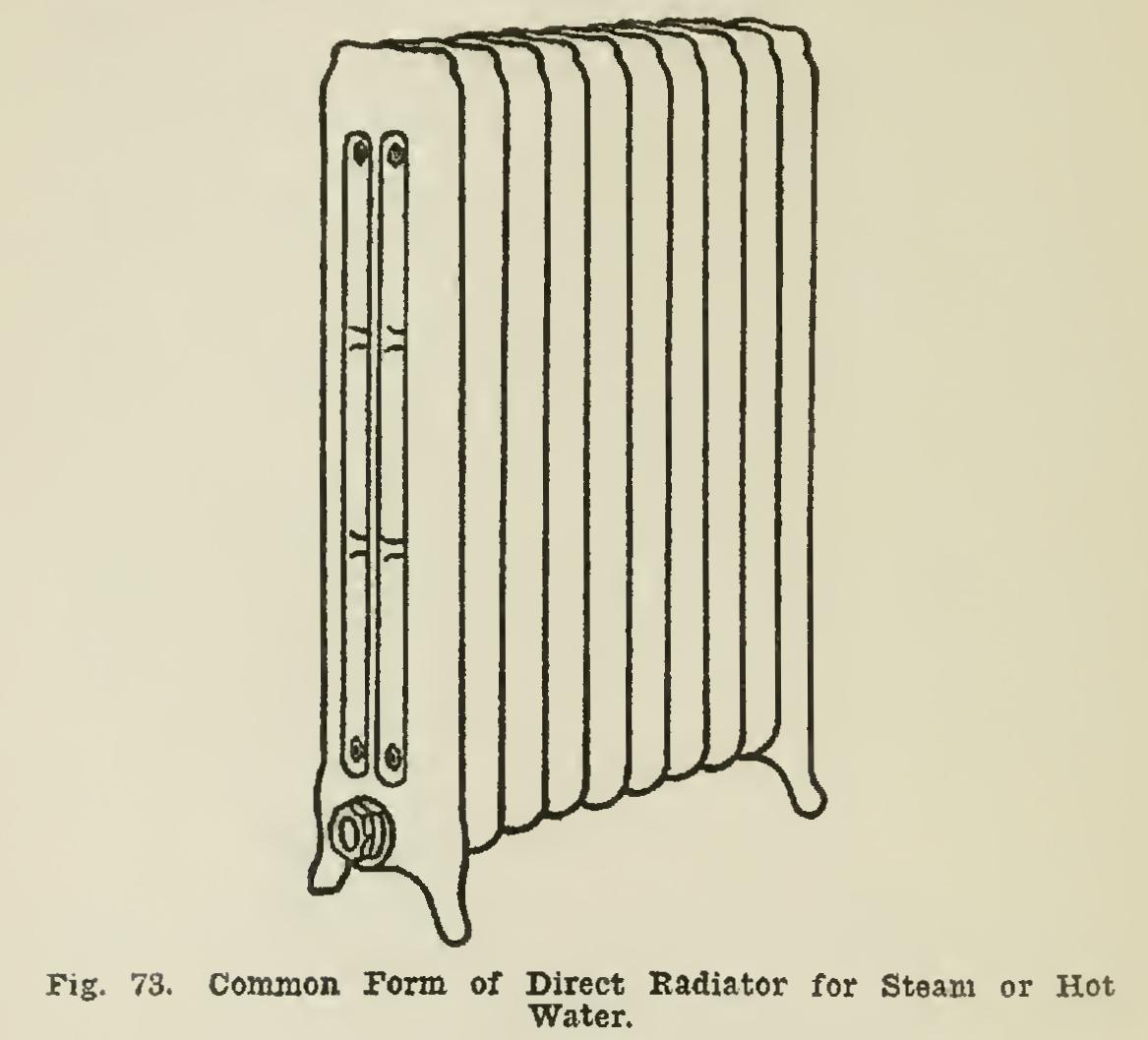

RADIATING SURFACES Radiating surfaces are to be had in a multi tude of shapes and designs adapted to any de sired space or location. They are manufactured of cast iron, wrought iron, and steel, and are pro duced either in the form of the ordinary type of column radiator or as pipe coils.

In heating systems, both steam and hot water, there are three varieties of radiation— namely, Direct, Direct-Indirect, and Indirect.

Direct Radiators

are located directly in the room or apartment to be heated. They are of the type illustrated in Fig. 73. This form of radiator and the pipe coils formerly installed for radiating purposes were unsightly, cumber some objects; but as now manufactured in a variety of beautiful designs, direct radiators are au ornament to the room in which they arc placed. Pipe coils at the present time are em ployed only in the heating of factories or build ings of similar nature.

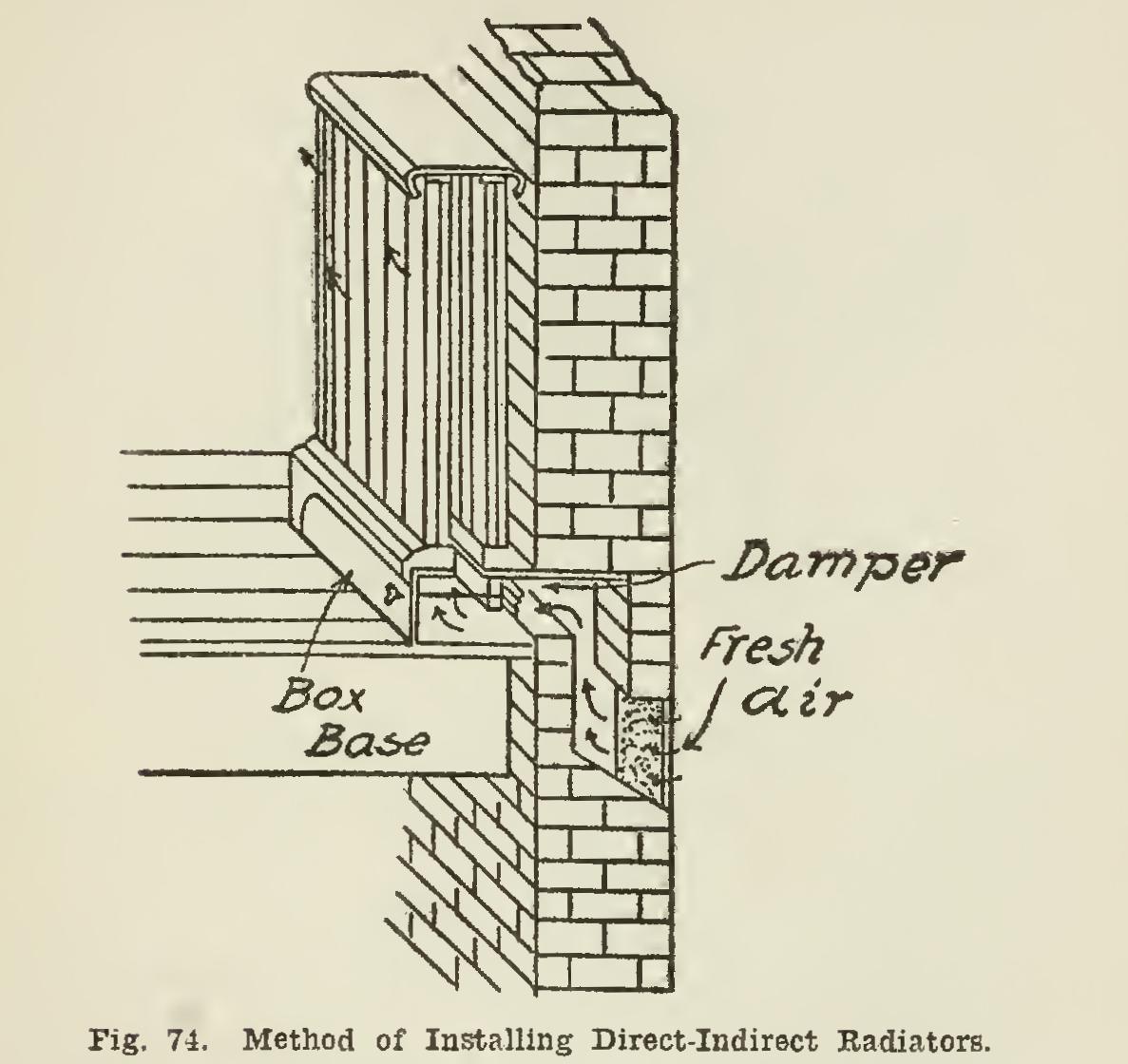

Direct-indirect radiators

are placed in the same manner as direct radiators, but also ar ranged with a box-base fitting under the lower part tightly. This box-base is provided with a damper; and an iron duct, connecting with au aperture in the wall, conveys the air from out side the building, admitting the supply to the boxing below the radiator, from which it is warmed by passing over the heated stulace of the radiator. Fig. 74 illustrates this type of radiation, which is largely used in buildings where it is necessary to provide specially for the admission of fresh air to assist in ventilation.

Indirect radiators are located outside the room, usually within a casing or bricked-in chamber in the basement. The pure cold air from without the building is introduced or car ried to the radiator through a pipe styled a cold air duct, the supply, after passing over and be tween the surfaces of the radiator, being carried through another pipe connection styled a warm air duct to a register situated in the floor or wall of the room to be heated.

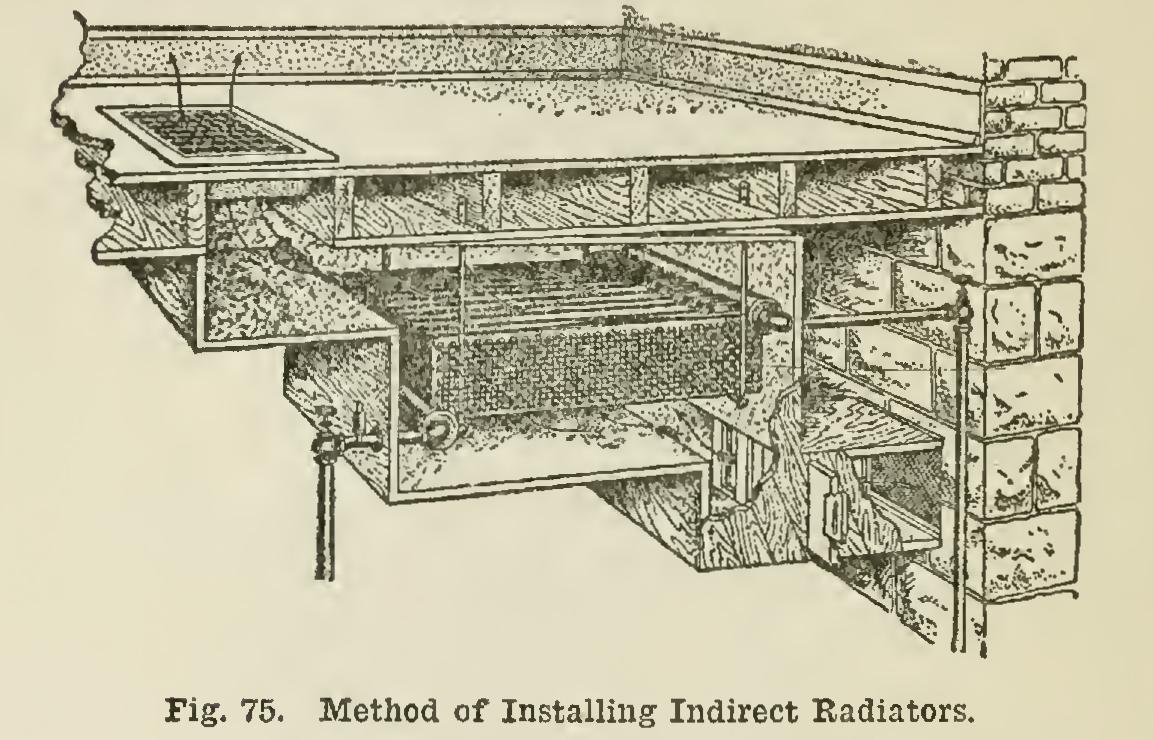

Fig. 75 illustrates the method of "indirect" heating. Several radiator sections are screwed or nippled together, and, when assembled, form a so-called stack of indirect radiation. Care must be exercised in boxing or casing such a stack, as it is necessary that the box or casing fit snugly against the stack in order to insure a passage of the cold air through the radiator and prevent a circulation around it.

The cold-air duet should be provided with a suitable damper in order that the cold-air sup ply may be controlled. It is customary to admit the outside air at and below one end of the casing, taking the warm or heated supply from the top at the opposite end.

The early methods of bricking a chamber for the use of indirects have been discarded in favor of portable boxing, which may be constructed of matched boards lined with tin, or, better still, may consist of a casing made of galvanized iron. The casing should be of such depth that a space of at least eight inches will exist between it and_ the lower side of the stack, and a space of ten or twelve inches between the top of the stack and the upper wall of the casing. The stack is usually supported on bars of iron or short lengths of or 1-inch pipe suspended from the ceiling by hangers.

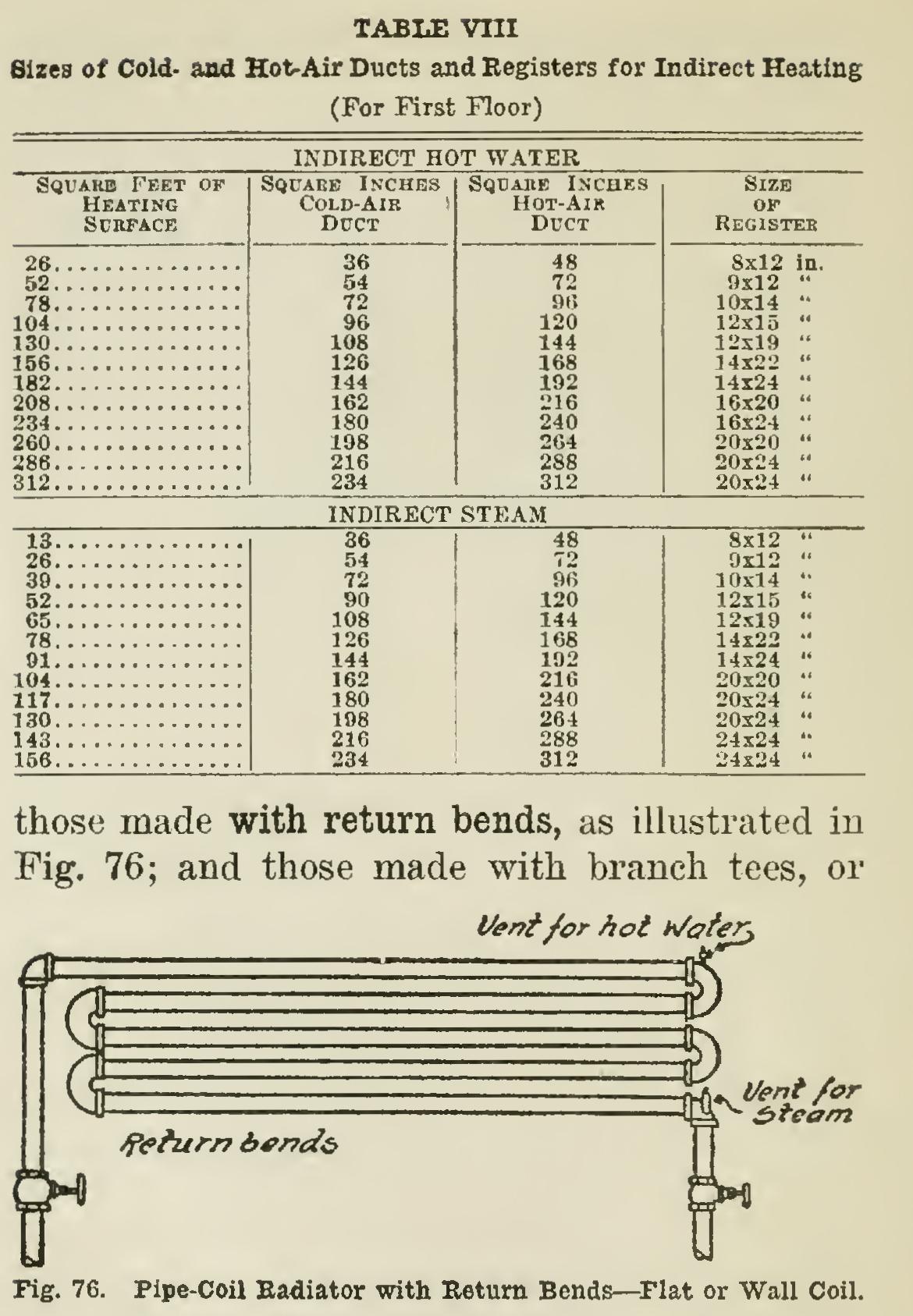

Table VIII indicates the proper sizes of reg isters and air ducts for indirect work.

Pipe coils, while largely used as radiation for factory and greenhouse heating, are seldom em ployed in house-heating work, by reason of the large amount of wall space they occupy. Quite frequently, in the early days of steam heating, it was the practice to assemble a mass of pipe coils and box them in on the sides and ends by cast-iron open-work or latticed panels, with a top either of cast iron or marble. This construc tion was known as a box coil—a type of coil now seldom if ever used, because of its cumber some appearance as well as its inefficiency.

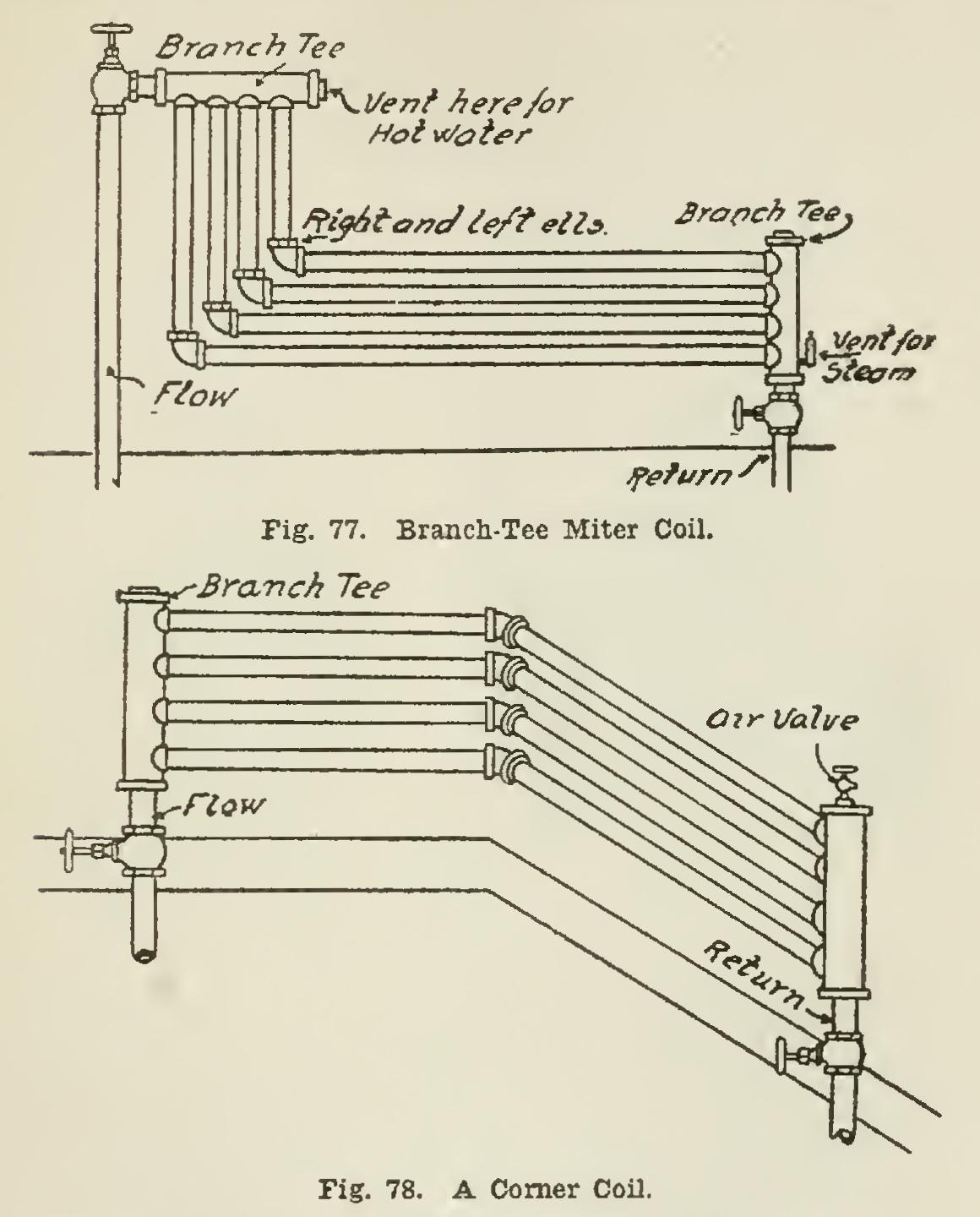

Coils of present-day use, while found in sev eral forms, are of two general varieties—namely, manifolds, as illustrated in Figs. 77 and 78. The return-bend coil of Fig. 76 is termed a flat or wall coil; that of Fig. 77, a branch-tee miter coil; and that of Fig. 78, a corner coil. While there are other forms also to be found, those illustrated are the ones in common use. As it is customary to connect all coils on the two-pipe plan—that is, with a separate flow and return pipe—the con structions will do equally well for both steam and hot water.