The Chimney Flue

heater, smoke, air, size, draught, smoke-pipe, inches, fig and flues

THE CHIMNEY FLUE In the construction of a building, there is one feature or part of it the efficiency of which is frequently overlooked or given but scant attention. We refer to the chimney flue. The perfect working of any one of the various types of modern heating apparatus depends largely upon the character of the chimney to which it is attached; and it is probable that ninety per cent of the failures of such apparatus to heat properly (when a heater of sufficient size and the proper amount of radiating surface are pro vided) are directly traceable to the chimney. A knowledge of the essential features to be con sidered in chimney building is therefore of the utmost importance.

Aside from the outlet at the top, the chim ney used with any heating apparatus should have no opening except that required to con nect the smoke-pipe of the heater. This opening should conform in size to the smoke connection on the heater. All manufacturers of furnaces, steam boilers, and hot-water heaters are care ful to indicate the size of smoke connection best adapted to the use of a certain size of heater, and this specified size should never be reduced.

The flue should start but a few inches below the smoke-pipe opening, the part of the chim ney beneath being constructed solid up to this point. Smoke in ascending a flue travels in a spiral form against the pressure of the atmos phere, and will not rise until the air in the flue is sufficiently lightened by expansion to over come this pressure, when it will be forced upward by the circulation caused by opening a draught door below the grate of the heater.

Flues are built round, square, and oblong; and the degree of efficiency of the three different styles is indicated in the order named. A brick flue with a round tile or iron lining, as illus trated in Fig. 92, is, without doubt, the best that can be procured, as the heated gases and smoke occupy its full area. The next best type is the square flue, illustrated in Fig. 93. The dotted line indicates the area of the flue reserved by the smoke and gases, the shaded portion denot ing the dead air space. The illustration of the oblong flue, Fig. 94, shows these features also, and the reader will note the increased propor tion of useless air space in this type. This condition may be carried to such an extreme— as, for instance, with a flue 4 by 16 inches—that the amount of dead air space will equal or even exceed that portion of the flue which is active surface, with the result that a down draught is produced, causing friction by mingling with the opposing current of air, and rendering the flue practically useless. A clear opening of an S by 8-inch flue, with an area of 64 square inches, would be far better and more efficient than a flue with an opening 4 by 24 inches, although the latter would have an area of 96 inches, or a capacity more than one-third greater.

A chimney erected through the center of a building is more efficient than one built in an outside wall, because it is surrounded by heated or Nvarm rooms which in a large measure prevent the condensation of the smoke, the cooling of the gases, and the precipitation of soot. When constructed in an outside wall, the

side of the chimney flue exposed to the air should be at least eight inches in thickness. In an outside chimney, the condensation of the smoke and gases from certain grades of coal will frequently cause the sulphur and creosote ingredients to run down the chimney into the smoke-pipe, by this action causing its rapid destruction. These products of combustion leave a dry deposit, which hardens to the con sistency of iron, clogging the dampers in the smoke-pipe or in the smoke-hood of the heater.

Offsetting

of chimney flues should, if possible, invariably be avoided. If conditions. however, make such a construction absolutely necessary, the angle of the offset should be as sharp as possible; otherwise the soot and ashes will form a deposit in the offset and clog up the flue. Fig. 95 illustrates this, and shows by dotted line how offset should have been made.

Height in a flue simply governs velocity, having no effect whatever on the area, which should be sufficient for the work demanded of it. A chimney in a building of two or more stories has sufficient height to be suitable for all purposes. It should extend above the build ing to such a distance that adjacent structures or roofs will not interfere with its working or cause a possible down draught by reason of the wind blowing over the roof and down through the chimney.

Trouble with draught on a heating system may be due to any one of the following causes: 1. Obstructions in flue, such as extensions of bricks or timbers, or an extension of smoke-pipe too far into flue opening, as shown in Fig. 96.

2. Loose or open clean-out doors at base of chimney.

3. Height insufficient to clear surrounding obstruc tions to draught.

4. insufficient area for work demanded of flue.

5. An enlarged or contracted chimney at some point in its length. A flue is only as large as the area at its smallest portion.

G. Two or more smoke-pipes from different apparatus connected to same chimney, one working against another.

7. Offsets at too great an angle—that is, too flat.

8. Loose division walls between flues, one of which is used for the heater.

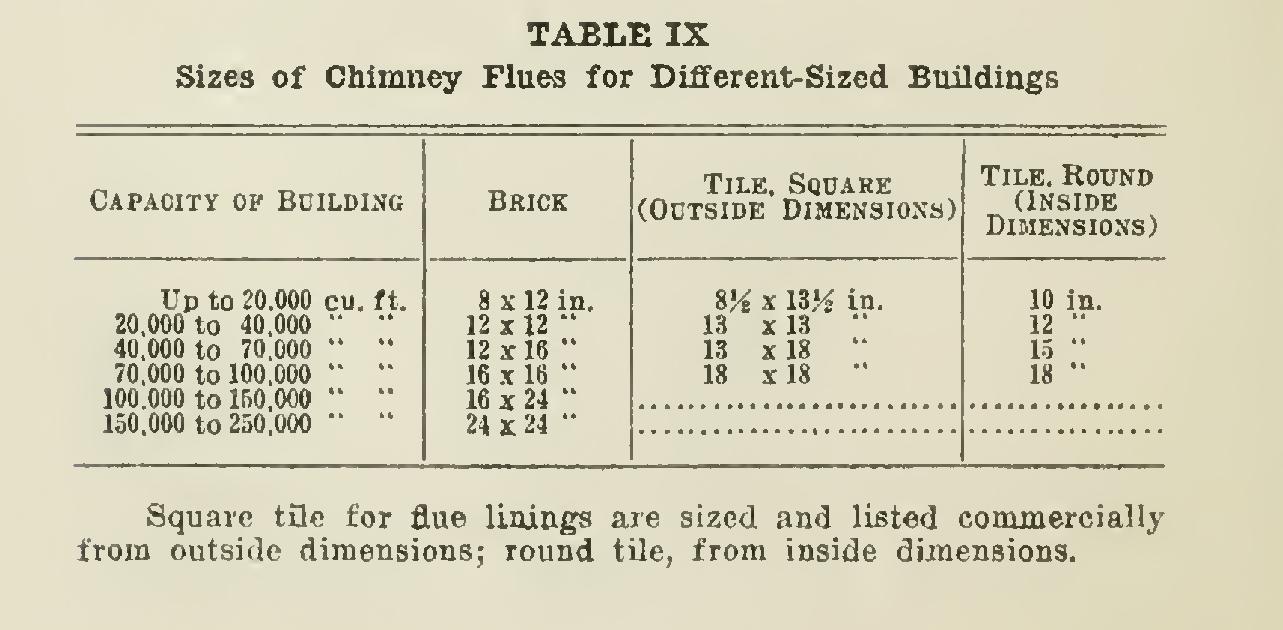

These are the causes of some of the diffi culties commonly experienced with chimneys, and their enumeration should prove a valuable aid in locating any possible trouble. As a guide to follow in the proper construction of a chimney, Table IX is given, which shows the proper sizes of brick and tile flues for different sized buildings. The dimensions of tile given are commercial sizes. The capacities scheduled have been found in practice to be entirely suf ficient for ordinary work, and can be safely relied upon to render proper results.