Vacuum and Vapor Heating

pressure, steam, system, water, air, pounds and boiler

This opens a passage for live steam to enter the tank from the boiler, and equalizes the pres sure therein with that in the boiler, thereby permitting this water to flow down into the retmla pipes and through check-valves C into the boiler, raising the water-line, and again cov ering tube end F and protecting it against the passage of steam by water seal.

After the discharging process, the steam which displaces the water in the receiving tank condenses, forming a partial vacuum therein, which relieves the check-valves C on the end of the return pipes entering the same, and permits accumulated air and water of the return pipes to be forced into this receiver, at the same time relieving them of any pressure and putting them under the same partial vacuum conditions which may exist in the receiving tank at this time.

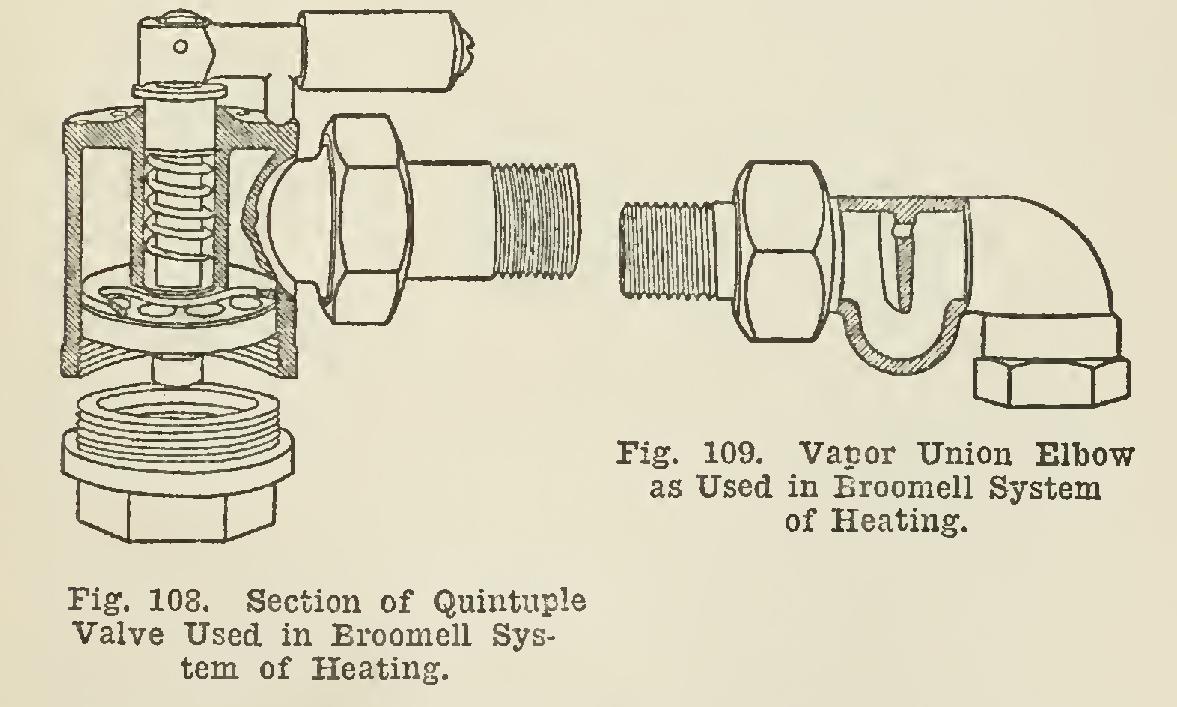

The Broomell system is a vapor method; that is, the pressure never exceeds ten ounces. A special form of valve, called a quintuple valve is applied on each radiator, its applica tion permitting of a sufficient amount of vapor to be admitted to the radiator in order to fill it one-fourth, one-half, three-fourths, or en tirely, as the case may be. Fig. 108 is a sectional view of this valve, showing the four holes or ports through the disc, which engage with similar ports through the seat of the valve. On the return end of each radiator is placed a special type of union elbow, Fig. 109, so con structed that it holds in check the vapor while the condensation is discharged into the return lines. The system of piping erected is in accordance with the two-pipe plan.

The real heart of the Broomell system consists of the combined receiver, draught regu lator, and relief apparatus, shown in Fig. 110. The system is open to the atmosphere through the receiver, making it impossible for the pressure at any time to exceed ten ounces; and by reason of the action involved, the fire is automatically controlled.

The piping for a vacuum job must be abso lutely tight throughout, in order to insure that no air can leak into the system and destroy the vacuum carried. For this same reason, the stuffing-boxes of all attached valves should be perfectly tight; or, better still, special packless types should be used. The boiler should be sup

plied with a compound pressure and vacuum gauge; and for small air-lines, the pipe and fit tings prove more suitable if galvanized.

Heating by the vacuum plan is sure to prove economical, because no steam pressure is necessary to drive the air from radiators when once it has been removed. Again, all heating surfaces are effective, due to the complete with drawal of any accumulated air and of the water of condensation.

The advantages of vapor and vacuum heat ing are many; and as the evident benefits derived from their usage are more and more understood by the heating contractor and house owner, such systems will be adopted to a much greater extent than heretofore. The ability to generate and circulate steam at reduced temperatures (practically as low as those em ployed in hot-water heating), together with the fact that by a complete removal of air all radiating surfaces are effective, insures an im mense saving in fuel as compared with the cost of operation of a job installed according to ordinary methods.

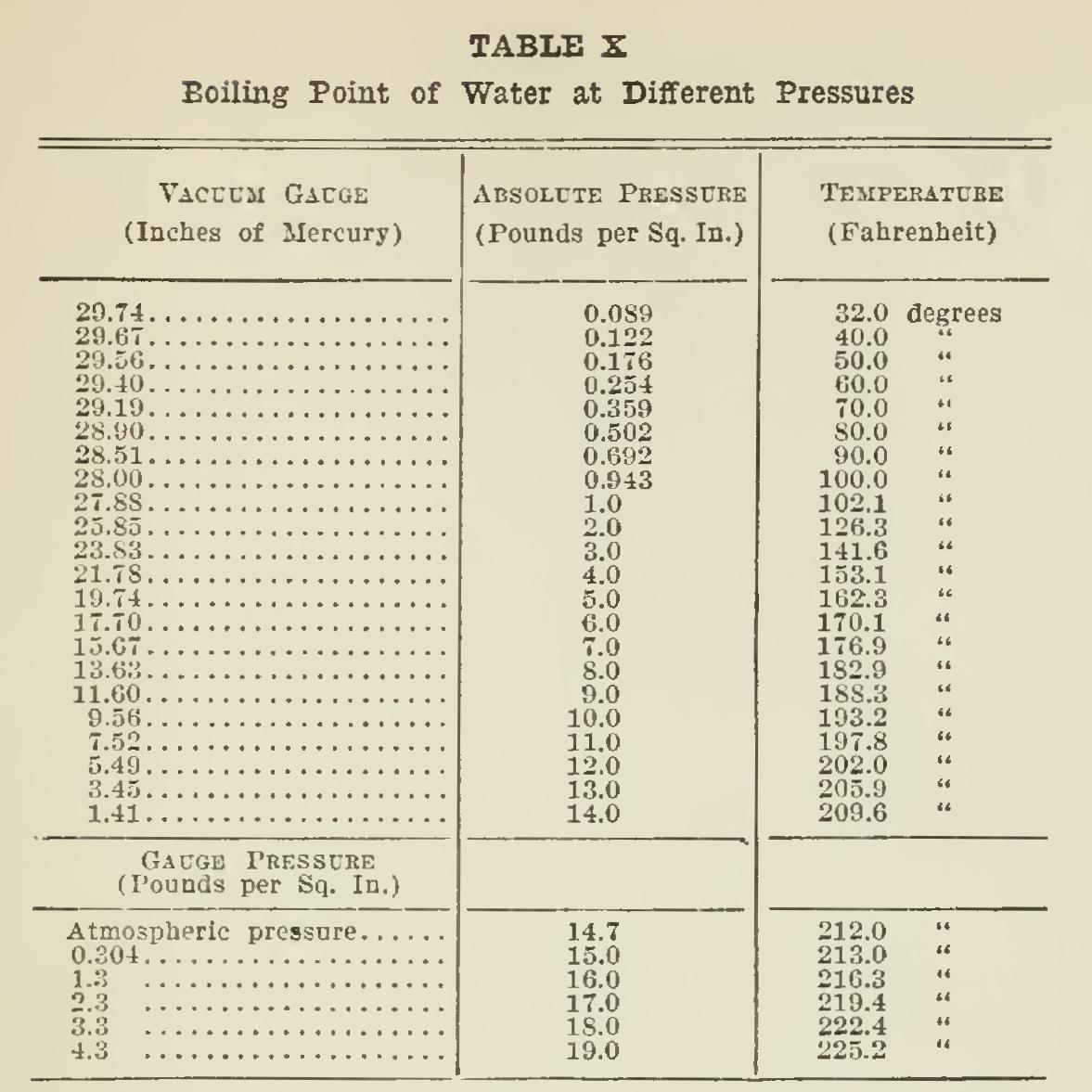

Table X gives the boiling point of water at different pressures, from complete vacuum (29.74 in. in the mercury column) to steam at 4.3 pounds pressure, or an absolute pressure (considering that of the atmosphere as 14.7 lbs.) of 19 pounds.

When it is fully comprehended that on the steam job as ordinarily installed no results are obtainable through the medium of the radiators until the atmospheric pressure of 14.7 pounds has been exceeded, since two pounds pressure, for example, at the boiler, means an absolute pressure of 16.7 pounds (14.7 + 2), we recog nize the great waste of heat units in the fuel consumed, the circulation never getting above the first floor unless a pressure of steam is con stantly maintained on the apparatus.

The ability to use this otherwise lost heat by circulating it through the heating system, as is the case with vacuum and vapor heating, results in a saving of from 20 per cent to 40 per cent, according to the conditions surrounding the work.