Boiler Accessories Valves

valve and steam

BOILER ACCESSORIES: VALVES Of all boiler accessories, perhaps the most important are the cocks and valves by means of which the flow of steam or water may be shut off completely or partially. The valve operates by moving a disc across the pipe in a transverse direction, or by bringing a cap tight upon the seat in a fore-and-aft direction. A cock consists of a block inserted in the passageway, with an opening cut through in one direction. When the handle of the cock is in line of the pipe, the opening allows the steam to pass through; but if turned crosswise, the opening is closed.

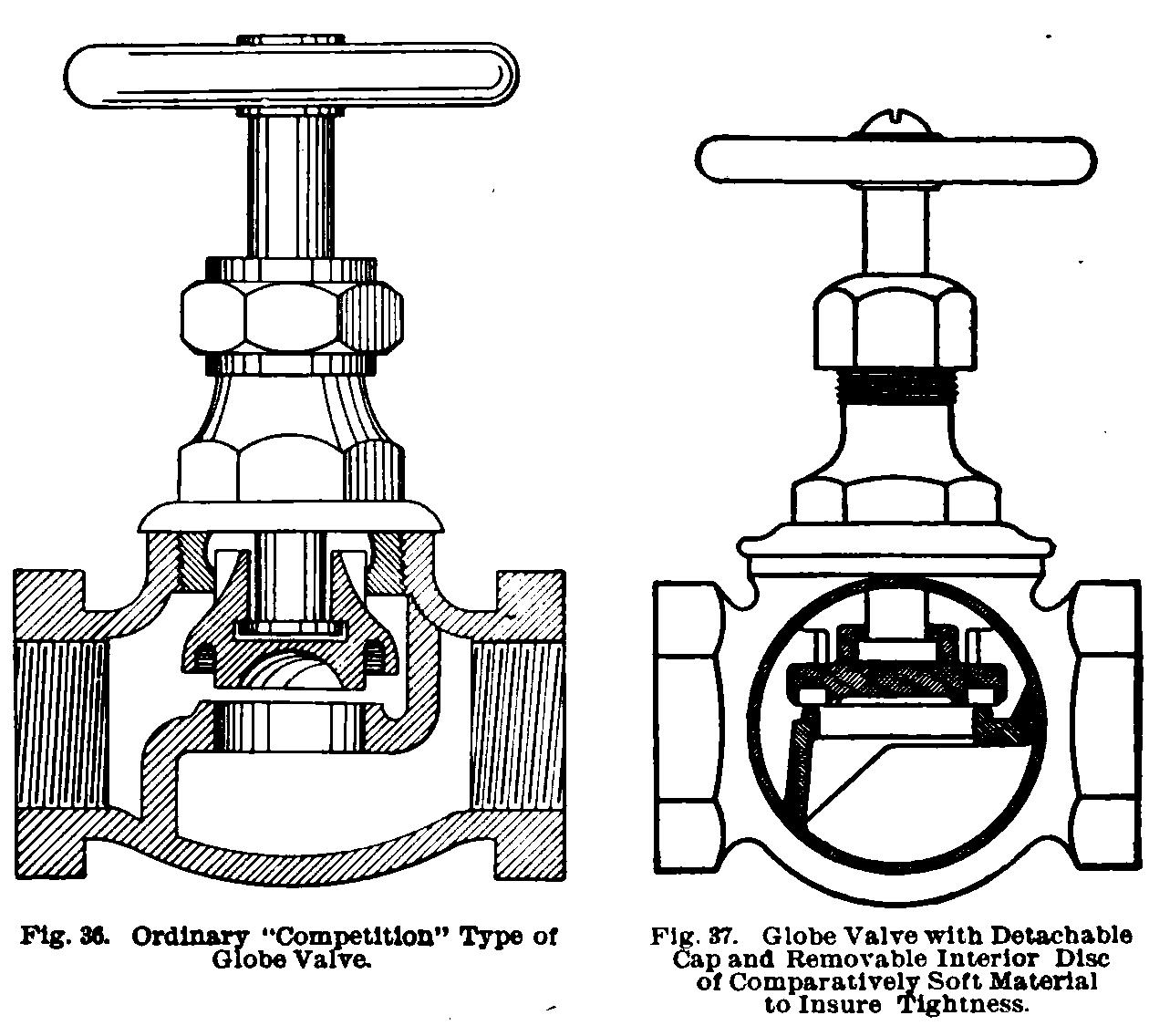

The Globe Valve. The valve shown in Fig. 36 gets its name from the globular shape of the casing which encloses the valve. Extending across this whole casing is a substantial diaphragm, the central portion of which is in a plane parallel with the length of the pipe. The opening is cut in this portion, horizontal in the figure, through which steam or other fluid may pass when the valve is opened. When the valve is closed, a cap is forced down to close its opening. The rim around the opening is known as the valve-seat. The valve-cap is operated by a spindle, which passes through the bonnet of the valve and is mounted at the upper end by a small wheel or handle. To prevent the escape of steam around this spindle, a stuffing-box is provided. The valvecap may or may not rotate as the spindle turns; usually it does not. The valve shown in Fig. 36 is the ordinary globe valve known to the trade as the "Competition" valve. It is the cheapest valve of the type, and is not satisfactory where absolutely tight work is required. If the cap becomes scored, the valve will leak and is then worthless.

A valve shown in Fig. 37 has a detachable valve-cap; and instead of relying for tightness upon the valve and seat coming together, metal to metal, a removable disc is provided, which being softer than the metal valveseat, easily takes up the wear, and the valve not only can be closed tighter, but if anything happens so that the tightness of the valve is impaired, the valve-cap can be replaced by another at a trifling expense. In the cheaper

valve, when the cap is scored, the valve is worthless. The valve-seat sometimes has a slight bevel, the valvecap being shaped like the frustum of a cone.

It is impossible to close a valve tightly if the slightest particle of scale or grit gets between the disc and the seat. If this happens, the valve-seat is likely to become scored so that it does not hold tight; but it may be reground, and if the valve disc itself is damaged, it can readily be replaced.

Angle Valves. An angle valve, shown in Fig. 38, is constructed ina similar manner to the ordinary globe valve, and is sometimes used in place of the straightway valve and an elbow. Both these styles of valve should be so placed in the steam pipe that the entering steam comes beneath the valve-seat. If this is done, the valve-stem may easily be repacked simply by closing the valve. If the steam enters in the opposite direction, a leaky valve-stein cannot be packed, as loosening the stuffing-box would permit the escape of the steam.

The Gate Valve. The gate or straightway valve gives a straight passage through the pipe, and, when open, offers very little resistance to flow. The globe valve, of course, offers much resistance, because the fluid has to change its direction of flow completely.

There are two forms of gate valve— one with wedge-shaped sides, and the other having the valve sides parallel. Fig. 39 shows a "Chapman" valve with wedge-shaped sides. A collar holds the valve spindle at a fixed point; and to open or close, the valve is drawn up or lowered by turning the spindle. When the gate reaches the bottom of the pipe, a wedge on the lower end of the spindle causes the sides to move laterally, with sufficient force to bring a strong pressure against the valve-seat. For heavy work, these valves are made with a rising spindle instead of a stationary one. This possesses the distinct advantage of indicating at a glance whether they are opened or closed; while one cannot tell by looking at the ordinary gate valve whether it is open or not.