Brick Chimney Construction a

glass and wall

Forms for casting these brick are shown in Fig. 130. Fig. 131 shows the method of pouring them full of concrete, also one manner of laying them in wall construction.

The brick have indented ends, and may be laid up with narrow mortar joints if desired. Good practice demands the making of a full mortar joint to prevent contact of the glass edges under undue pressure.

Glass brick are bonded to courses of other material in the same manner used in pressed-brick work, by metallic tees or headers. All colors of which glass is capable can he produced in glass brick. Bricklayers handling this product should be enjoined against undue hammering of the brick when placing them in the wall. The brick may be cracked by so doing. If laid perfect in the wall, they will remain so, being impervious to all temperature and moisture changes. In the glass-faced brick, the cement of the concrete adheres to the glass; and a dovetailed rib of glass traverses the entire length of the back of the facing, making a very effective bond.

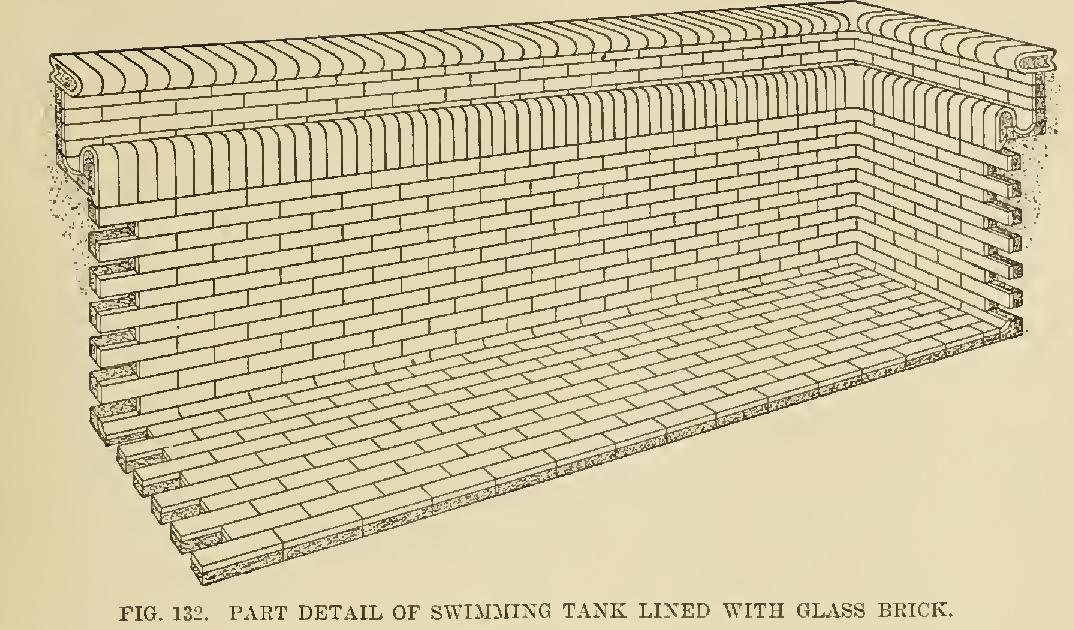

Figs. 129 and 132 show glass brick used for a fireplace and a swimming pool respectively. For swimming pools, cisterns, etc., these brick are claimed to be especially serviceable. The brick proper need not be concrete-filled. They can remain hollow to remove surface seepage.

Fig. 131. Pouring Class Brick. Showing also method of wall construction.

Hollow Brick. Hollow brick are often used for backing brick and for damp eourses. They are the sae size as the ordinary brick, and They bond M the wall. They are laid so that the openings run through the wall when serving as damp courses, to allow ventilation and evaporation.

Vitrified Clay Conduits. These are specifically made for the laying and insulating of electrical cables and wires. They are exceptionally strong, being vitrified. and are being used with suceess for the foundation and inside walls of stucco houses. They are rondo 1-way, 2-way, or with multiple passages, and square, oblong, or triangular as desired.

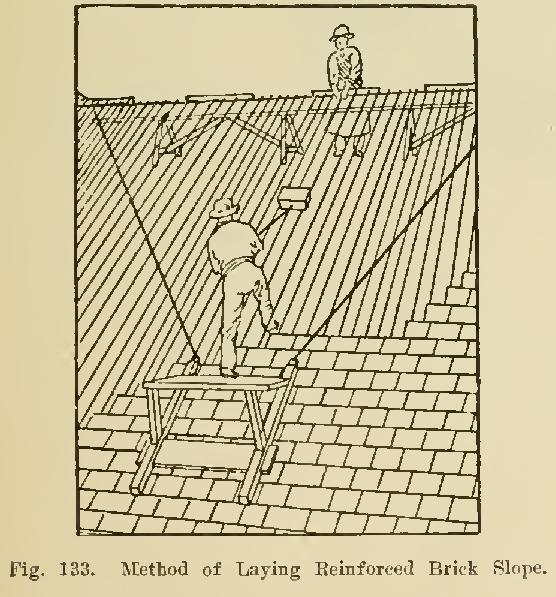

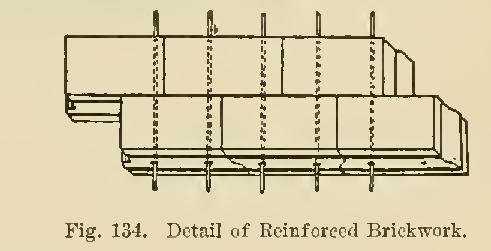

Reinforced Brickwork. The pioneer of reinforced brickwork was Cottancin, a French engineer. More recently the claims of reinforced brickwork have been advocated by two or three specialist firms, and used with 'considerable advantage in the construction of walls and floors in industrial and other buildTugs. The latest application of the same prin. ciple is exemplified by various river and canal banks in France, which are faced with reinforced brickwork, as illustrated in Figs. 133 and 134. The bricks are pierced by two holes for galvanized or copper wires, and are set as follows: The slope to be protected is finished to the required gradient, and the reinforcing wires are secured to a cable stretched along the bottom of the slope. The free end of each wire is then attached to a horizontal frame at the top of the slope, where the bricks are threaded on the wires and slid down to the bricklayers. When the work has passed beyond reach from ground level, the layers stand upon a small platform, as shown in Fig. 133; and, on completion of the facing, the upper ends of the wires are securely anchored.

Size of a Brick Hod. A brick hod measures from 20 to 22 in. in length, and 8 in. on the sides. Its load is from 16 to 20 brick.

Size of a Mortar Hod. The average length of a mortar hod is about 22 in. in length, and its depth on the sides ranges from 12 to 14 in.