Brick Construction

shown and wall

When part of the bricks are darker than others, the dark ones are frequently selected as headers, with pleasing results.

A corner built with Flemish bond to look alike in front and back, is shown in Fig. 28. Bats are shown at points a. The brick b is split to secure the proper spacing in both front and back. The course above that shown is built to break joints with this one. The face of the wall is like that in Fig. 27. This is a 13-inch wall, in which the narrow brick is shown at a.

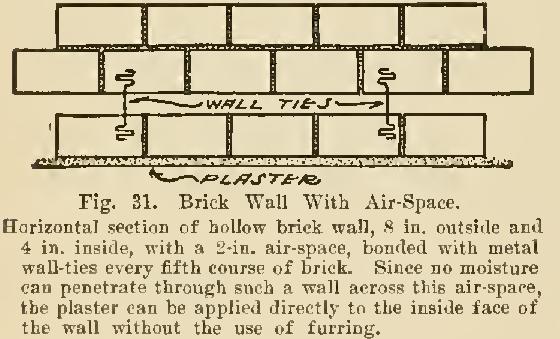

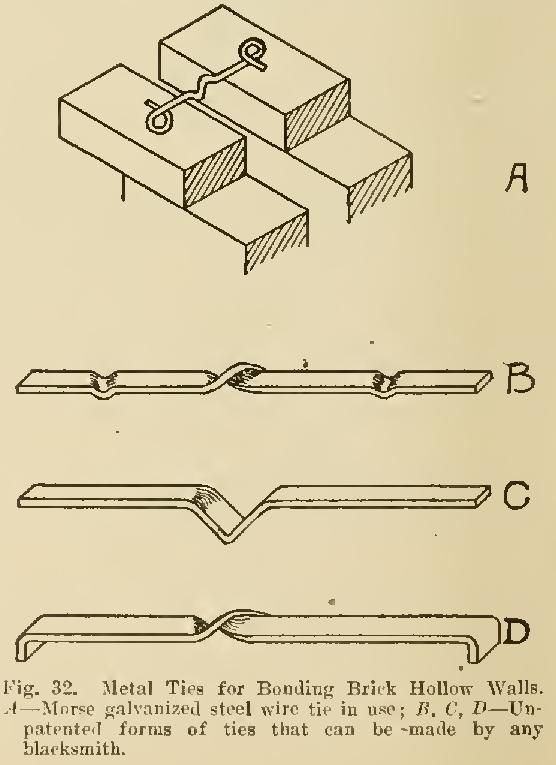

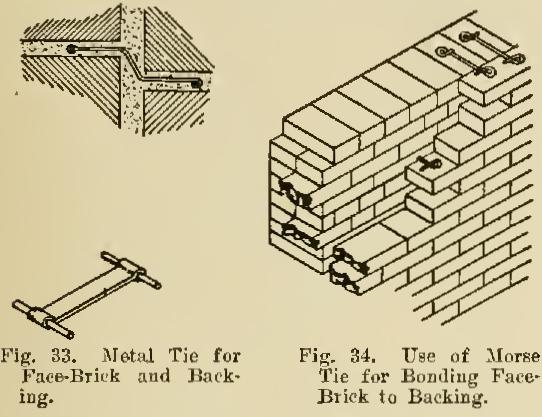

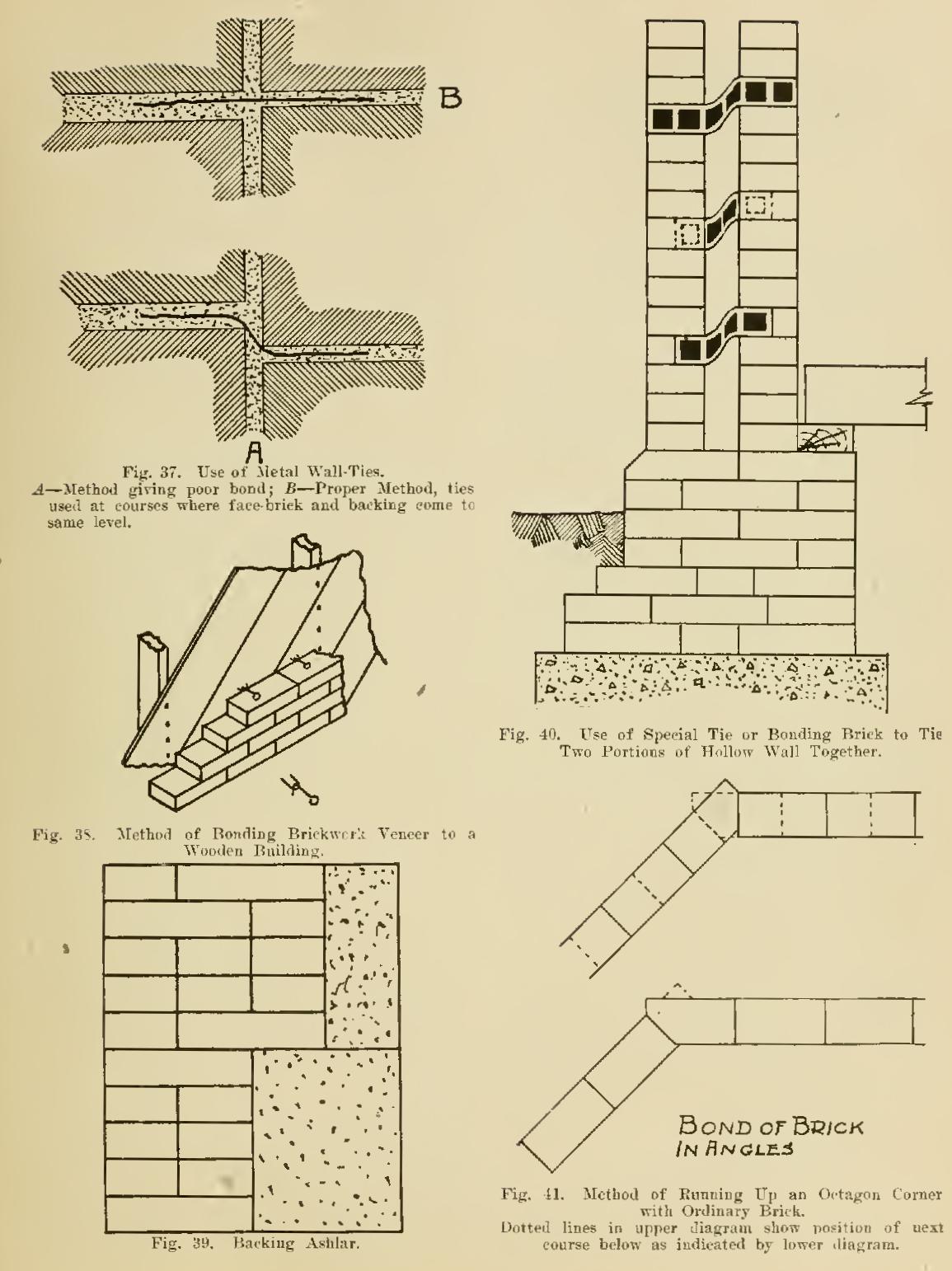

Plumb bond, American bond, or Diagonal bond is generally used when the walls are faced with pressed brick. The face brick are laid as stretchers, with the joints plumb above each other from bottom to top of wall (see Fig. 30). The bonding of the face to the common brick is made by clipping off the back corners of the face bricks about every sixth course, laying diagonal headers behind. It is not a good method of bonding, but answers certain requirements under special conditions, such as might be haposed by A.n endeavor to save waste of face-brick headers, and by difficulty arising from face brick and common brick not coming out to exactly the same heights. This last difficulty—which is by no means uncommon—is offered a solution by means of galvanized steelwire wall-ties, as Shown in Fig. 31. By means of these ties, made in lengths of from 7 to 16 in., differences between the levels of the face and backing courses are made negligible, as the ties can be bent to conform to any existing difference. When these ties are used, good practice calls for bonding every fourth course with one tic to each face-brick.

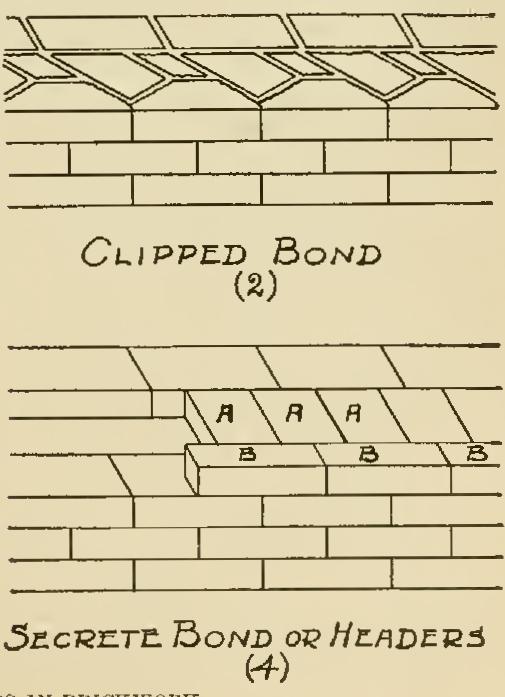

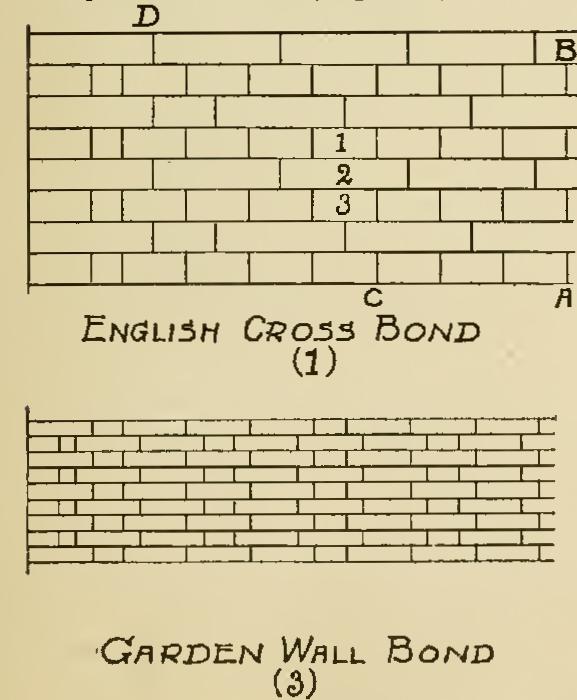

English cross bond (Fig. 35-1) differs from the regular English bond only by the stretchers of the successive courses breaking joint with each other as well as with the headers in adjoining wallcourses. A supposed St. George's cross effect in the wall-pattern gave the bond its name. The bond is more attractive than the regular English type.

Pieces of hoop-iron laid flat in the bed-joints of brickwork, arc used to give longitudinal strength and to prevent cracks through uneven settlement.

This practice is known as Hoop-iron bond.

A method of bonding a veneer of brickwork to a wooden building by means of iron wire hooks, is shown in Fig. 38.

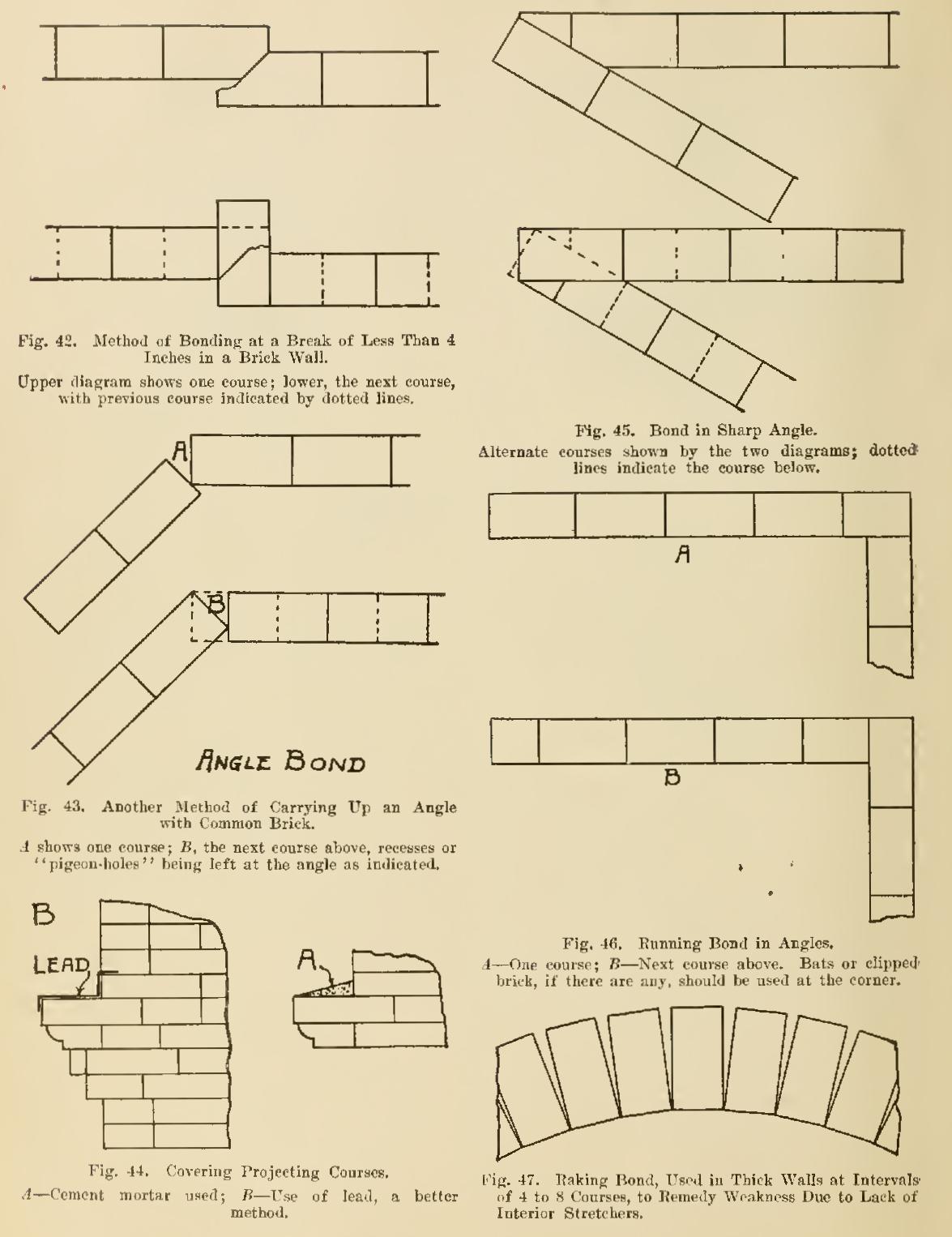

Bonding Brickwork in Angles. Various methods of bonding brick walls under different conditions, are shown in Figs. 41-46. The titles and the illustrations are sufficiently explanatory to obviate the necessity of extended description.

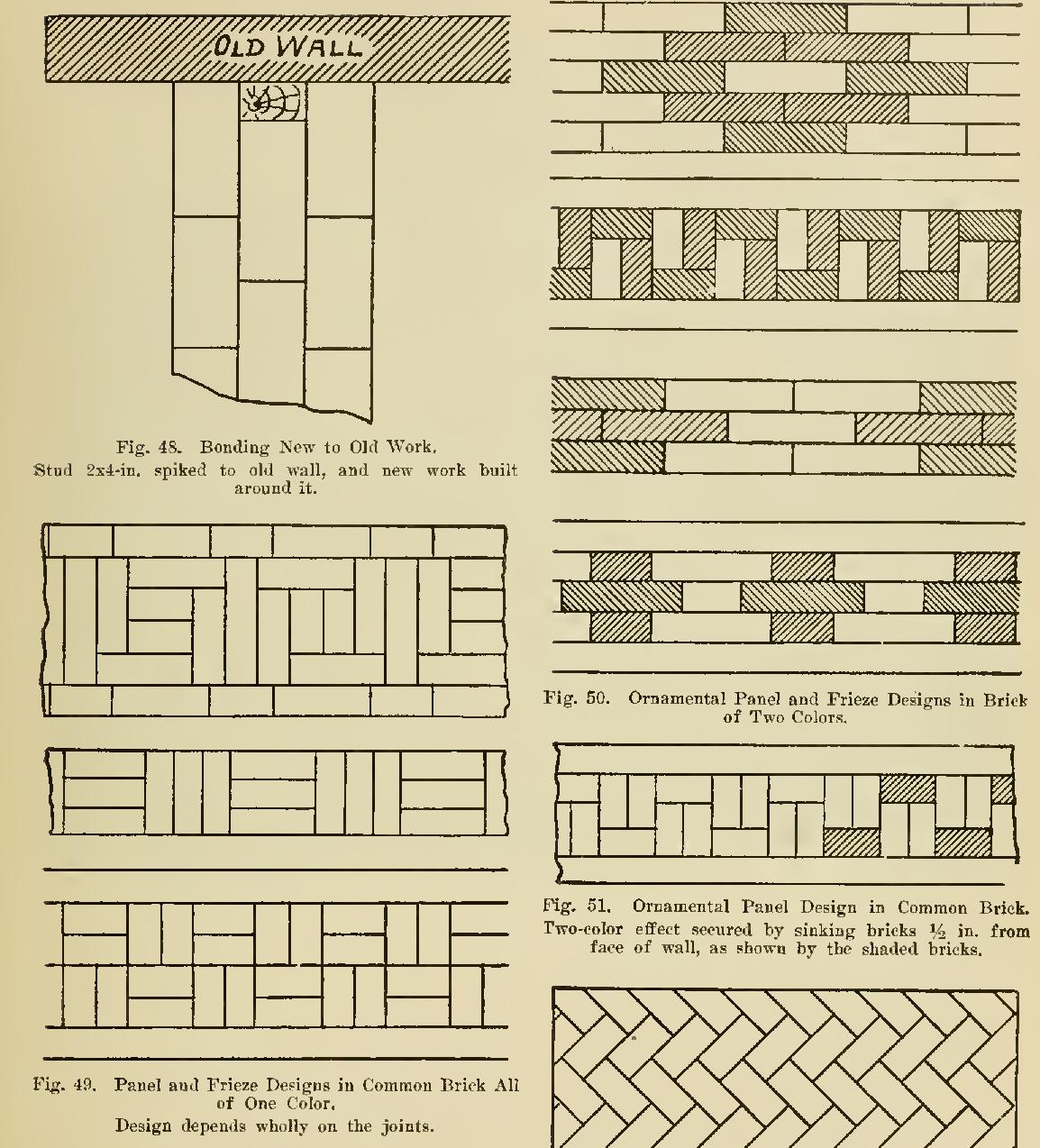

Bonding New to Old Brickwork. In making additions to or special alterstions in buildings, where a new brick wall adjoins an old wall, it is advisable to anchor them together. This can be done either by taking out some of the old brickwork and inserting the iron anchors in the spaces thus provided, or a 2 by 4-in. studding can be spiked to the old wall, and the new wall can be built around it, as shown in Fig. 48.

Ornamental Effects Produced with Plain Brick. In Figs. 49-52, an inter: csting study is presented of some of the many designs that can be produced with ordinSry brick for panels, friezes, borders, etc. The shaded brick repre table for receiving water. Its advocates claim it shows a smoother wall.

The joint at B, known as a weather joint, is the opposite of A. It is more difficult of accomplishment, but sheds falling water. It is opposed because, sent the contrasts obtained by the use of two colors of brick.

Pointing for Brickwork. In Fig. 55, the different styles of pointing brickwork are shown. The struck joint shown at A is the most common. It is made with the point of the trowel, which rests on the lower course of brick and is guided by the top course as it is drawn along. It would seem that this is a joint horn of operative necessity, as it is the easiest one to make from the inside of the wall. It is often objected to because it offers a in looking up the wall, the observer can see the projections of the under side of the brick shown by the in-strike. As to appearance, choice between A and B is a matter of taste to be decided by those who favor smooth- or rough-appearing wall surfaces. B is undoubtedly the most weather-proof.