Worsted Manufacture

wool, slivers, spinning, rollers, gill-box, sliver and preparing

WORSTED MANUFACTURE. The essential feature of a worsted yarn is straightness of fibre. Prior to the introduction of automatic machinery there was little difficulty in attaining this characteristic, as long wool was invariably employed and the sliver was made up by hand and then twisted. With the introduction of Arkwright's "water frame" or "throstle" the necessity for prepared slivers became apparent, and with the later introduction of cap and mule spinning the necessity for perfectly prepared slivers has been so accentuated that the preparatory machinery has quite exceeded the actual spinning machine in extent and complexity. To-day there are three distinct methods of producing worsted yarn. First, there is the preparing of the sliver and spinning of the true worsted thread, this being made from long English or colonial wool. In this class should also be included mohair and alpaca. Secondly, there is the pre paring and spinning of what are known as cross-bred and botany yarns, these being made from cross-bred and botany wools. Thirdly, there is the preparing and spinning of short botany wools on the French system. There is a fourth class of worsted yarns, principally carpet and knitting yarns, which are treated in a much readier manner than any of the foregoing, but as the treatment is analogous—with the elimination of certain processes—to the second of the foregoing, it is not necessary to refer specially to it.

To obtain a sliver or "roving" which can be satisfactorily spun into a typical worsted thread the following operations are neces sary:—preparing (five or six operations), back-washing, straight ening, combing, straightening and drawing (say six operations), and finally spinning on the flyer frame.

Preparing.

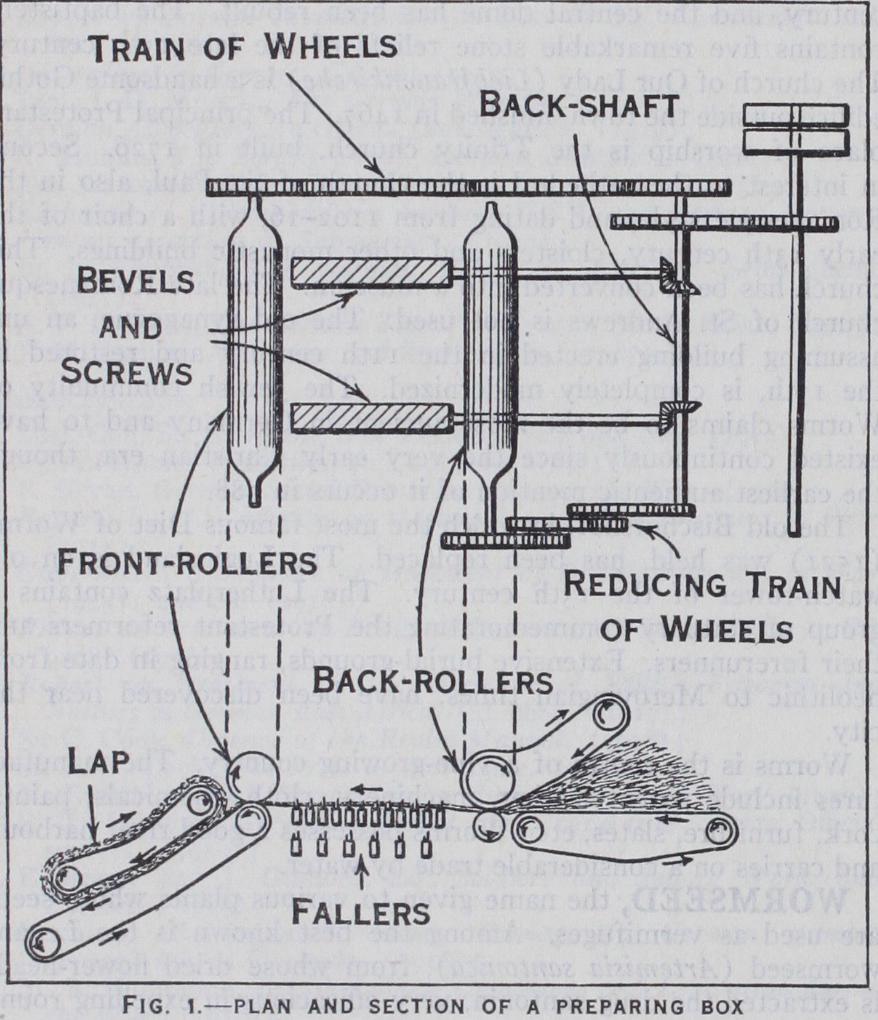

After long wool has been scoured and dried it is necessarily considerably entangled, and if it were to be combed straight away a large proportion of the long fibres would be broken and combed out as "noil" or short fibre. To obviate this the wool is fed as straight as possible into a sheeter gill-box; after this it passes through other two sheeter gill-boxes, then through say three can gill-boxes. As shown in fig. 1 the main features of a preparing or gill-box are the following: the feed sheet upon which the wool is "made up," the back rollers which take hold of the wool and deliver it to the fallers which, working away from the back rollers more quickly than the wool is deliv ered, comb it out. The fallers in turn deliver the wool to thefront rollers, which, taking in the wool more quickly than the fallers delivering it, again draft and comb it, but with a reversing of the former combing operation. The wool emerges from the front rollers as a thin attenuated continuous film about 12 in. wide, which is wound upon an endless leather sheet from which the box takes its name. When a sliver of sufficient thickness has been wound upon the sheet, it is broken across and fed up at the next gill-box. The fourth gill-box delivers into cans instead of on to a sheet. A number of cans are then placed behind the fifth box and the slivers from these fed up into the back rollers, and simi larly with the sixth. The primary object of "preparing" or gilling is to straighten and parallelize the fibres in the sliver. This is effected by means of the combining or doubling and drafting to which the slivers are subjected.