Worsted Manufacture

comb, fibres, wool, combing, circle, circles, wools, short and combed

Combing.

Prior to the mechanical era wool was combed im mediately after scouring; there was no preparatory process. As a matter of fact the first combing process took the place of the processes just described and was termed "straightening," the "combing proper" following. Prior to the invention of a really satisfactory mechanical comb, between 185o and 186o, the comb ing operation was the limitation of the worsted trade. English wools could be satisfactorily combed by hand, and perhaps the results of combing botany or fine wools by hand were satisfactory so far as quality of result was concerned, but the cost was largely prohibitive. The history of the colonial wool trade is inextricably bound up with the combing industry. How eventually botany wools were combed by machinery and how the wool industry was thereby revolutionized can only be briefly referred to here. About 1779 Dr. Edmund Cartwright invented two distinct types of combs, the vertical and the horizontal circular. The former type was developed on the Continent by Heilmann and and has only within the last twenty years taken its rightful place as a suc cessful short wool comb in this country. The latter type was worked upon by Donisthorpe, Noble, Lister, the Holdens and others, and largely through the "driving" force of Lister (later Lord Masham) was made a truly practical success about the year 185o. Latter-day combs of this type may be readily grouped under three heads. The Lister or "nip" comb is specially suitable for long wools and mohair and al paca. The Holden or square-mo tion comb is specially suited for short and very good quality wools.

The last type, the Noble, is the most popular of all and, by a change of large and small circles, may be adapted to the combing of long, medium or short wools. As the great bulk of cross-bred and a considerable proportion of botany wool is combed upon the Noble comb a brief description is here called for. The object of all wool combing is to straighten the long fibres and to comb out from the slivers treated all the fibres under a certain length, leav ing the long fibres or "top" to form the sliver which is eventually spun into the worsted yarn. The Noble comb, which so effectually accomplishes this, consists in the main of a large revolving pinned circle A inside which revolve two smaller pinned circles B, B' as shown in fig. 3, each of which touches the larger comb circle at one point only. At this point the slivers of wool to be combed are firmly dabbed into the pins of both the large and small circles. As the circles continue to revolve they naturally begin to separate, combing the wool fibres between them, the short fibres or "noil" being retained in the teeth of both small and large circles, the long fibres hanging on the inside of the large circle and on the outside of the small circle. A stroker or air blast at F now directs these long fibres towards the vertical rollers, G and G', shown here in plan, which separate them from the short fibres.

There are at least four pairs of drawing-off rollers in a comb, and the fibres drawn off by each—be it noted continuously—are united to form a sliver which is passed through a revolving funnel into a can. The short fibres, or "noil," are lifted out of the pins of the small circle by "noil knives." The continuous slivers, the ends of which remain in the pins of the large circle after the drawing-off rollers have been passed, are now lifted up until these ends are above the pins, at the same time an additional length of sliver being drawn into the comb, so that, as the slivers reach the second small circle, they are ready to be again dabbed into the pins of both circles and the combing operation is repeated. Thus the combing on a Noble comb is absolutely continuous. All the movements of this machine—with the exception of the dabbing brush motion—are circular, so that mechanically it is an almost perfect machine.

After combing it is usual to pass the "top" through two gill boxes termed "finishers." The last of these boxes, and often the first, delivers the "top" in the form of a ball, thus it is often spoken of as a "balling gill-box." This stage marks one of the great divisions of the worsted trade, the comber taking the wool up to this point, but now handing it 'forward in the shape of top to the "worsted spinner," who draws and spins the slivers into the most desirable worsted yarns.

Drawing.

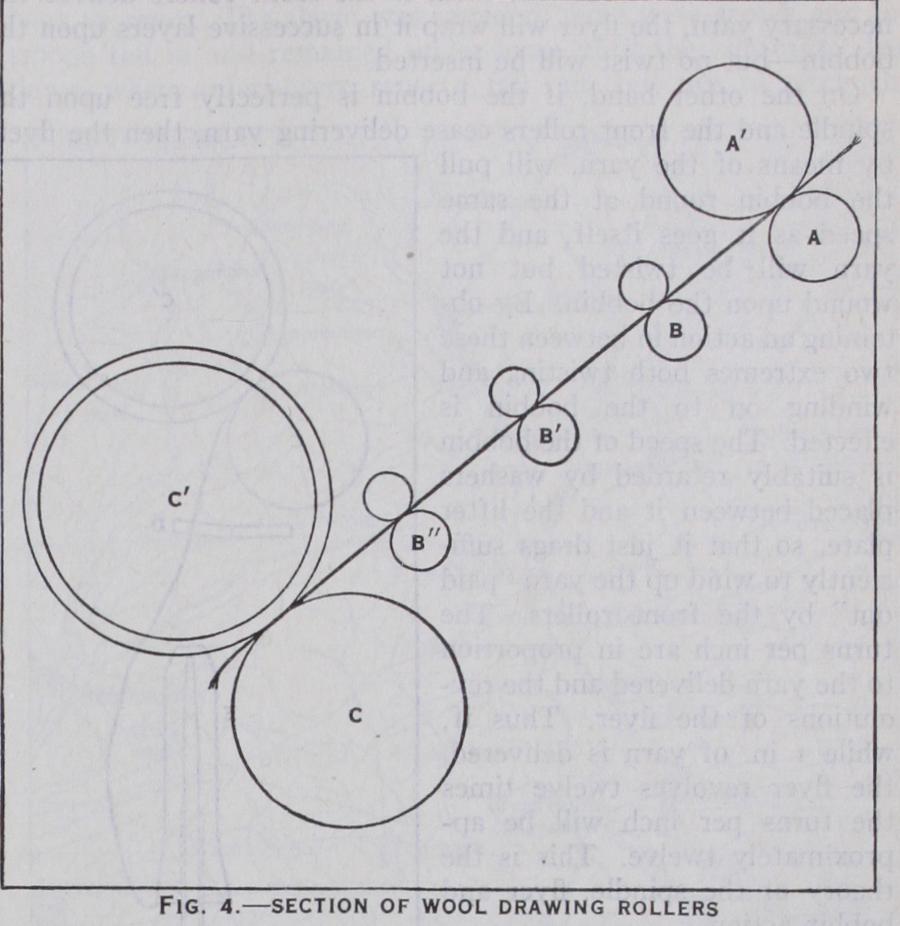

English tops are usually prepared for spinning by seven or eight operations. Three of these operations are effected in gill-boxes of a somewhat similar type to the preparing-box, only lighter in build. The remaining four are drawing-boxes, i.e., as shown in fig. 4, they consist of back and front rollers with small carrying-rollers—not gills—to support the wool in between. Thus an English set of drawing usually consists of a single-can gill box. a double-can gill-box, a two-spindle gill-box, a four-spindle drawing-box, a four-spindle weigh-box, a six-spindle drawing-box, two six-spindle finishers and three thirty-spindle rovers. About fifteen flyer frames of i6o spindles each will be required to follow this set, although the balance varies partly in accordance with the counts spun to, 1/32's English being the standard.

The object of drawing is to obtain firstly a level sliver from which an even thread may be spun, and secondly to reduce the comparatively thick top down to a rela tively thin roving from which the required count of yarn may be spun. Of course par allelism of fibres must be retained through out, so far as possible. To accomplish these objects doubling and drafting is resorted to. Thus the ends put up at the back of the above boxes will be 6, 6, 4, 4, 3, 3, 2 re spectively, while the drafts may be 5, 6, 8, 8, 6, 9, 9 approximately. As the drafts markedly preponderate over the doublings so will the sliver be reduced in thickness.