Lumbering

lumber, log, mill, plant, sorter, manufacturing, time and lengths

Sawmill Practice.

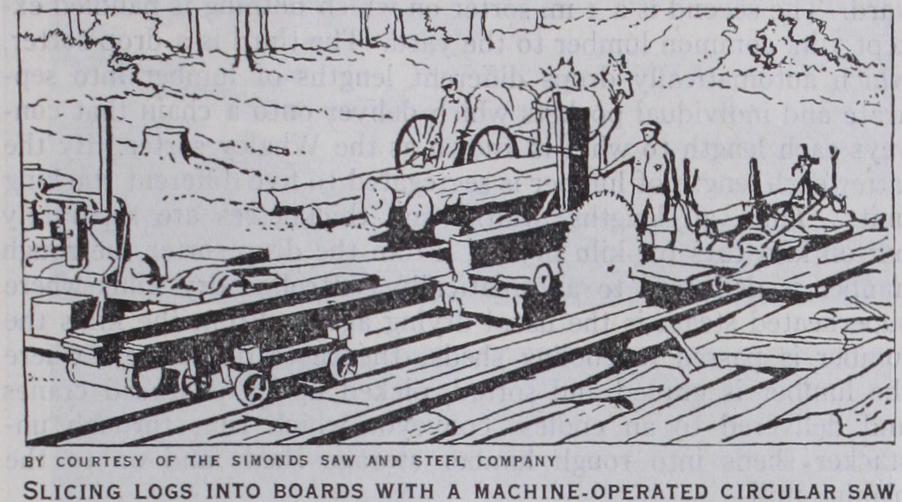

The first sawmills in the United States, as noted, were built at Jamestown, Va., and Berwick, Me., and were modelled of ter the European type of mill, employing water-power and a single sash-saw.

Production was small until steam power supplanted water-power about the year 185o. About the same time the single sash saw gave way to the circular saw and the latter was widely used until about 189o, at which time the band-saw became popular in the larger mills. For the next 20 years lumber production in creased rapidly. Many new inventions and more efficient methods of operation brought the lumber industry to the front with almost astonishing rapidity. Most modern sawmills employ the same general type of machinery and follow somewhat similar plant layouts. Band-saws of varying types such as single-cutting, double cutting, vertical and horizontal band-resaws and gang-saws are common in the larger mills. Many labour-saving devices are em ployed. Various types of conveyors and other machinery permit the log to enter the mill and pass out as manufactured lumber with very little handling or moving by hand.

The modern methods of lumber manufacture are so intricate and so efficient as a rule, that the term "sawmill" has given way to that of "lumber manufacturing plant." The largest lumber manu facturing plant in the world in 1928 at Longview, Wash., con sisted of two groups, each a complete unit consisting of more than 3o buildings. The two units combined have a total of 78 ac. under roof, and the total plant site covers 1,737 acres. Storage and cutting ponds cover 125 acres. The power-plant, which sup plies electricity for both the lumber manufacturing plants and the logging operations some 3o m. away has a present capacity output of 24,000 kilowatts, and can be increased to 36,00o kilo watts whenever necessary. The power-plant derives its fuel from sawmill waste. The daily output of the two lumber manufacturing units is approximately 2,000,00o bd. ft. of Douglas fir.

Mill Process.—The following method of lumber manufacturing is prevalent, with variations to fit certain local requirements. The logs enter the head mill from the pond over an inclined chute or "log slip." They are transported by an endless spiked conveyor known as a jack ladder or jacked chain. As they ascend the slip they are sprayed with water to remove grit and dirt that might otherwise dull the saws. From the slip the jack ladder carries the log under a large circular saw known as the deck saw and which is used if the log is to be shortened; otherwise the log is "kicked" off onto the log deck by steam-driven steel arms. From the log

deck the log rolls onto the log carriage. A steam or air "nigger" (mechanically operated steel arms) helps to place the log in the proper position. The carriage is a long, flat platform which is made to travel back and forth rapidly on a track, keeping the log against a band or "head" saw which squares it and reduces it into flitches or cants. The log is turned from time to time on the carriage by means of the steam or air operated "nigger." If the log is to be used as a timber, it is squared and edged and then passed immediately to the rear of the mill where the timber dock usually is located. If to be converted into lumber, the flitches or cants enter the remanufacturing plant directly behind the head mill, where they pass to the gang-saws and edgers and then to the trimmers.

From the remanufacturing plant the lumber passes through sorters and to explain this step the following description is given of a large modern lumber manufacturing plant in the North-west. Joining immediately on the end of the remanufacturing mill are three sorters. The first is a 2 in. yard sorter where nothing is handled except 2 in. common lumber, all lengths and widths, which will be segregated into various packages as to grades, widths and lengths. These packages are then delivered by a monorail hoist to cars which are drawn by storage battery locomotives to the green yard. The second is a 1 in. sorter on which nothing is handled ex cept 1 in. common lumber to the yard. The third is a drop sorter, which automatically drops different lengths of lumber into sep arate and individual pockets which deliver onto a chain that con veys each length to what is known as the Whaley sorter. By the latter each length of lumber is segregated to five different stacking units. Thus, all lengths, widths and thicknesses are separately put on kiln cars for kiln drying. From the drop sorter the rough lumber is delivered to automatically controlled dry kilns where superheated steam is the usual drying agent. From the kilns the lumber is passed to cooling sheds; thence to dry sorters where the lumber is graded and sorted, picked up by overhead cranes and delivered to an endless conveyor which runs through un stacker sheds into rough lumber storage sheds and on to the planing-mill.