Lumbering

lumber, industry, future, ft, lengths and forests

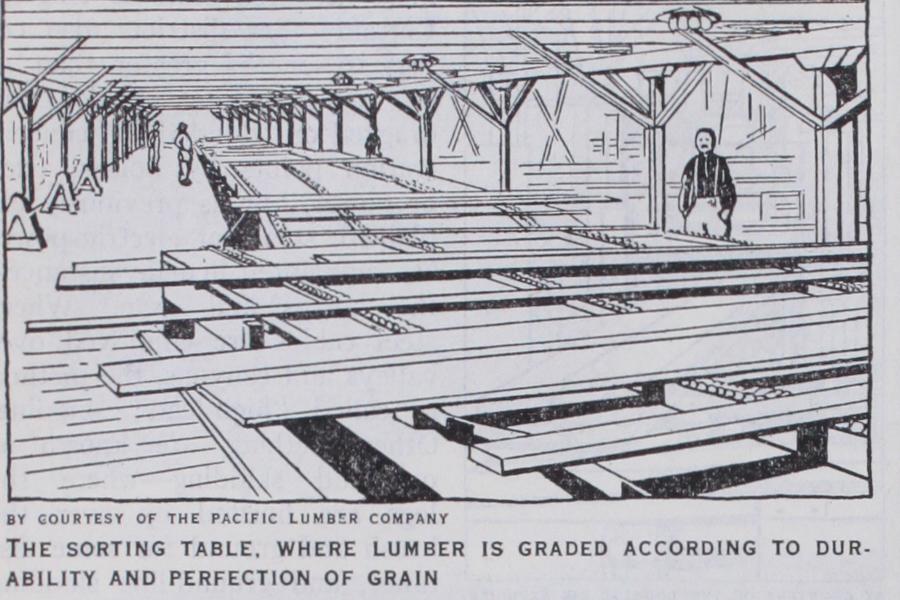

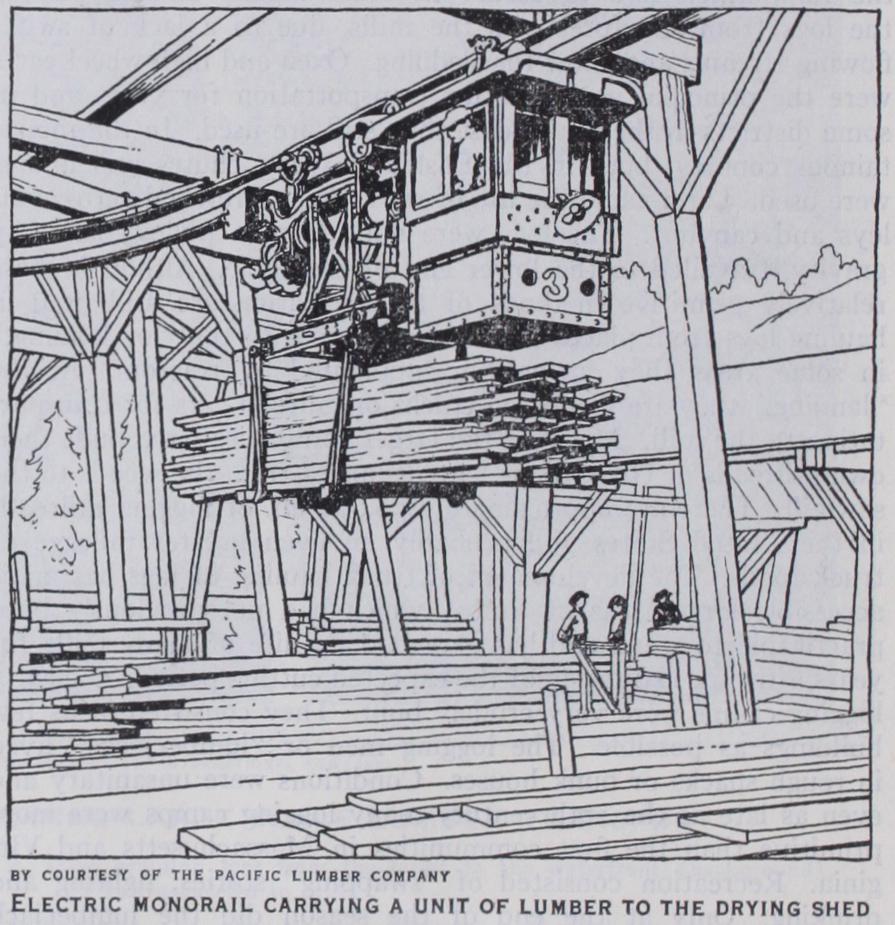

Not all lumber passes from the kilns to the planing-mill, a very important and necessary part of a lumber manufacturing plant. Some of it is placed in stock. Other packages pass on to the planing-mill where the lumber is surfaced as plain boards and "dimension" or worked into "ceiling," "flooring," "siding," "mould ing," "partition," "casing," etc. From the planing-mill the lumber is conveyed to the "dressed lumber" sheds to be stored or to the loading sheds, ready for shipment. Waste resulting from the various steps of manufacture is converted into "short length" lumber wherever possible; some of it goes into the manufacture of paper and pulp board, and some is ground up for fuel. Wood is the principal source of fuel for power in lumber operations. The larger slabs and edgings may be converted into lath and small wooden items.

The migration of the lumber-producing centres from the Atlan tic to the Pacific coast has been of great economic importance in the opening up of new territories for agricultural and various other industrial purposes. In all probability, the future will see lumbering having just as much effect, if not more, upon the economic development of America as it has had in the past. The consumption may rot increase with such rapidity, nor are there new virgin forests to be worked, but neither does any other pres ent major industry promise to develop as rapidly in the future as in the past, for the industrial zones of the United States are more or less permanently fixed and established. A steady increase in the demand for lumber will keep pace with the increase of popu lation and development of industry. In the past lumber has been "mined." In the future timber crops will be harvested.

By proper reforestation methods and programs, America should always be able to grow sufficient lumber to meet her needs. Since the beginning of time, new forests have arisen on the old, and wherever a forest area consists of old-growth, matured-timber growth is approximately balanced by decay. Like all other crops,

trees must be harvested to permit proper regrowth. In the future, lumber will come from forests regrown under scientific manage ment—sometimes from seedlings and sometimes from hand plant ing. This means that not only will present-producing forests continue to be productive, but also part, if not all, of the 76,738, 000ac. of forest land, non-productive in 1936, will be brought back in time to a state of production. The future will see a more efficient use of lumber. Much good lumber goes to waste because of the public's expensive habits. Nearly one-third of the lumber used by the building industry is finally consumed in lengths under 8 ft.; io% more is under 9 ft.; or a total of 43.6% of all lumber consumed in building is in lengths under 9 ft. Yet, it has been customary to buy lumber in lengths of 14, 16, 18 and 20 ft.

Trees cannot be changed ; but we will change our lumber-buying habits. We are already using more and more of the "short lengths" cut at the mills because it is less expensive and, in many cases, bet ter suited for general building requirements. The Government, in dustry and the public are co-operating to bring about these things. Since 1918 the lumber industry, in co-operation with consuming industries and the U.S. Government, has done much to standardize its product through the creation of the American lumber standards and has been engaged in a program for developing the market ing of American standard, trade-marked, grade-marked lumber.

Production, (U.S. Forest Service and Census Bureau, 1936) ; Lumber Distribution and Consumption, 1936 (U.S. Forest Service, 1938) ; Lumber Industry Facts (National Lumber Manufacturers Association, 1939). (R. A. Lo.; G. J. L.)