A Linen Chest

top, bottom, moulding, hinge and gains

While the glue of these parts is setting, square the bottom of the chest, and cut the cor ners. Smooth the surface carefully before put ting it in place, using plane, scraper, and sand paper. Since the gains in the posts were laid off for three-quarters of an inch, but very little wood can be removed in smoothing this piece. A better plan would be to smooth the bottom before cutting the gains, laying off the gains to suit the thickness of the bottom.

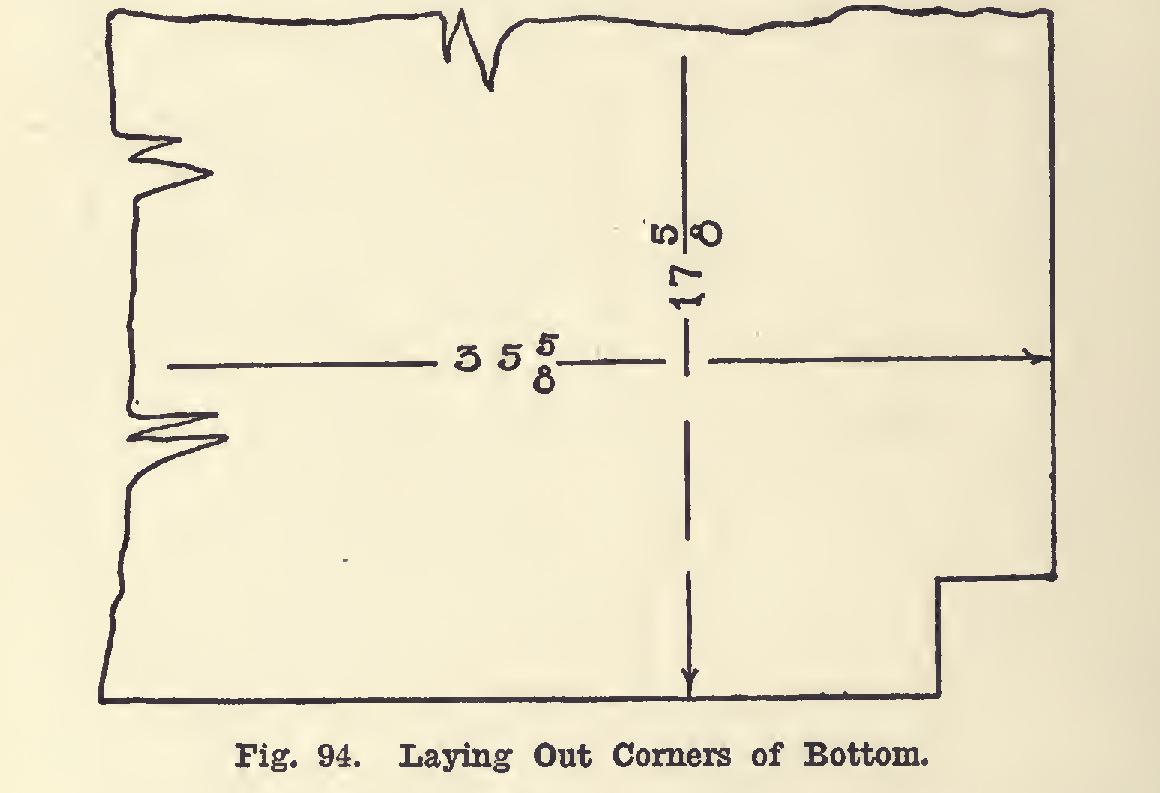

To lay out the corners of the bottom (Fig. 94), measure from each corner each way, along edge and end, one and seven-sixteenths inches. Square, and gauge lines at these points. Rip and crosscut to these lines.

Glue the tenons of the end panels, and clamp the chest together, carefully adjusting the bot tom to the gains.

"Break" a small egg-and-dart moulding in the eight corners where panel and post adjoin. Seventeen inches is the exact length of each piece. Nail through the moulding into the post only. If the stile of the panel should shrink, it will then not draw the moulding away from the post. This moulding should be not more than three-sixteenths of an inch in depth.

The top is to have three cleats fastened to the under side of it. They may have the edges and ends of one side of each beveled, if desired. Fasten them to the top, using screws. Holes will have to be bored through the cleats, and countersunk to receive the heads. About eight screws to the cleat will be sufficient. Fig. 91 shows the manner of placing them. The position of the cleats should be measured off and marked accurately, so that the top may be adjusted to the sides properly when hinging. The slight

bevel shown on top in Fig. 91 would be better omitted if ornamental corner-pieces such as are shown in the perspective are to be used.

The hinges used may be common butts of a size to fit the three-quarter-inch rail to which one side is to be fastened. The easiest way to set these hinges is to cut sufficient depth out of the rail to allow the whole hinge to be sunk level with the top of the rail. The top of the chest may then be placed, and the position of the hinge upon it indicated. The part of the hinge fast ened to the top will not need to be "set in" by this method, but will be simply screwed fast. A neater piece of work would result if the hinge were to be let into the top and rail equally. • As for a finish, it all depends upon one's likes and dislikes. Many satisfactory stains are on the market. Mission oaks, weathered oaks, etc., would look well. If one prefers a smooth sur face with dull waxed effect, it may be obtained by applying stain, filler, and wax. The direc tions for each will be found printed in full upon the cans.

The ornamental corner-pieces should har monize with the finish. Corner-pieces suitable for this chest can be purchased at the hardware store in brass or possibly in old copper or wrought iron.

The angle-irons under the chest are intended for ornament, as well as to reinforce the corners.