Joinery

fig, angles, tenon, joints, angle, styles and rails

JOINERY.

The term "joinery," applied in a general sense, includes all the finishings to the carcass of a build ing, whether they be external or internal, such as doors, windows, stairs, skylights, and all kinds of panelling,—in fact, it may be said to include every thing that is planed and wrought up to a nice smooth and often ornamental face, and framed together in such workmanlike and precise manner that it is difficult to discern the joints unless helped by the different grain and color of the stuff, as the wood is called.

It is intended to devote most of this chapter to a description of the various joints, mouldings, and terms which are used in this particular branch of building but the principal and most common joints, etc., will be pointed out to the student when they are met in the different kinds of joiner's work.

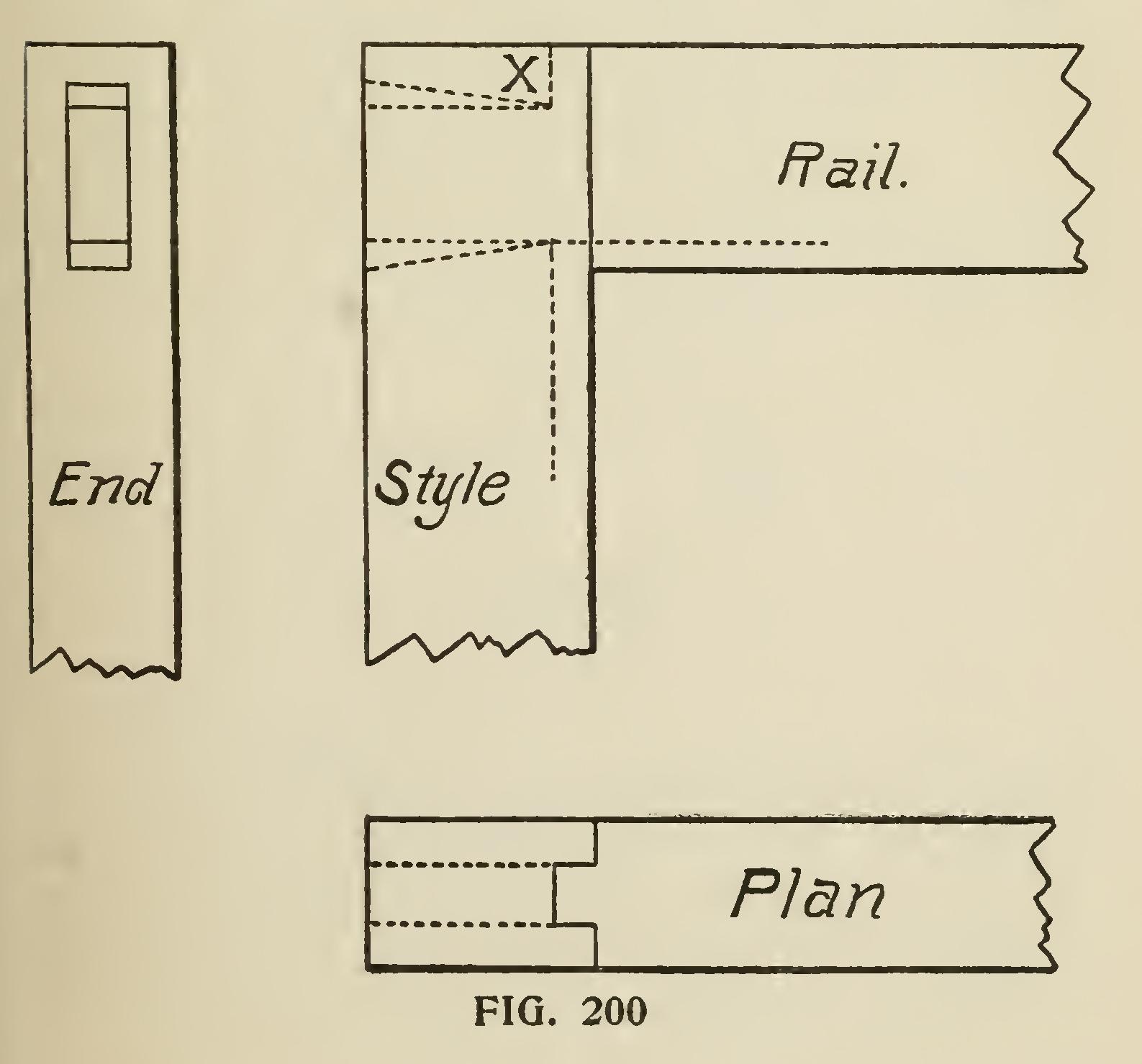

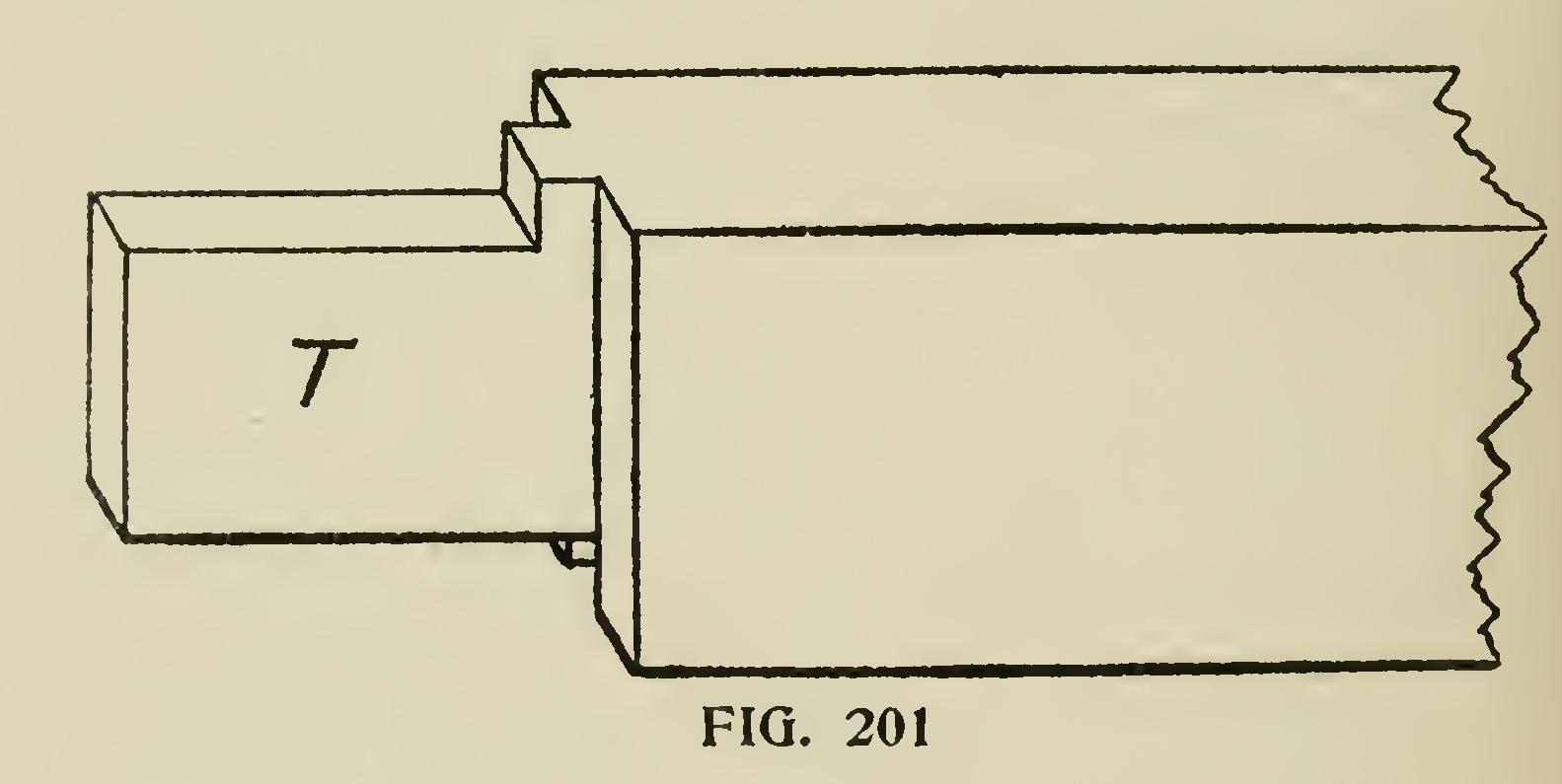

Framed Joints.—The mortise and tenon is the chief and most common of all the joints used in joinery framing. All rails of doors, for instance, are tenoned through the styles and wedged up tight, as Fig. 200, the tenon usually being one third of the thickness, and with a haunch left on as at X, to fill up the panel groove on the styles and strengthen the joint. This is the origin of the term haunched tenon, a sketch of which, as it is on the rail before being wedged up into the styles (as shown in Fig. 200), is given in Fig. 201.

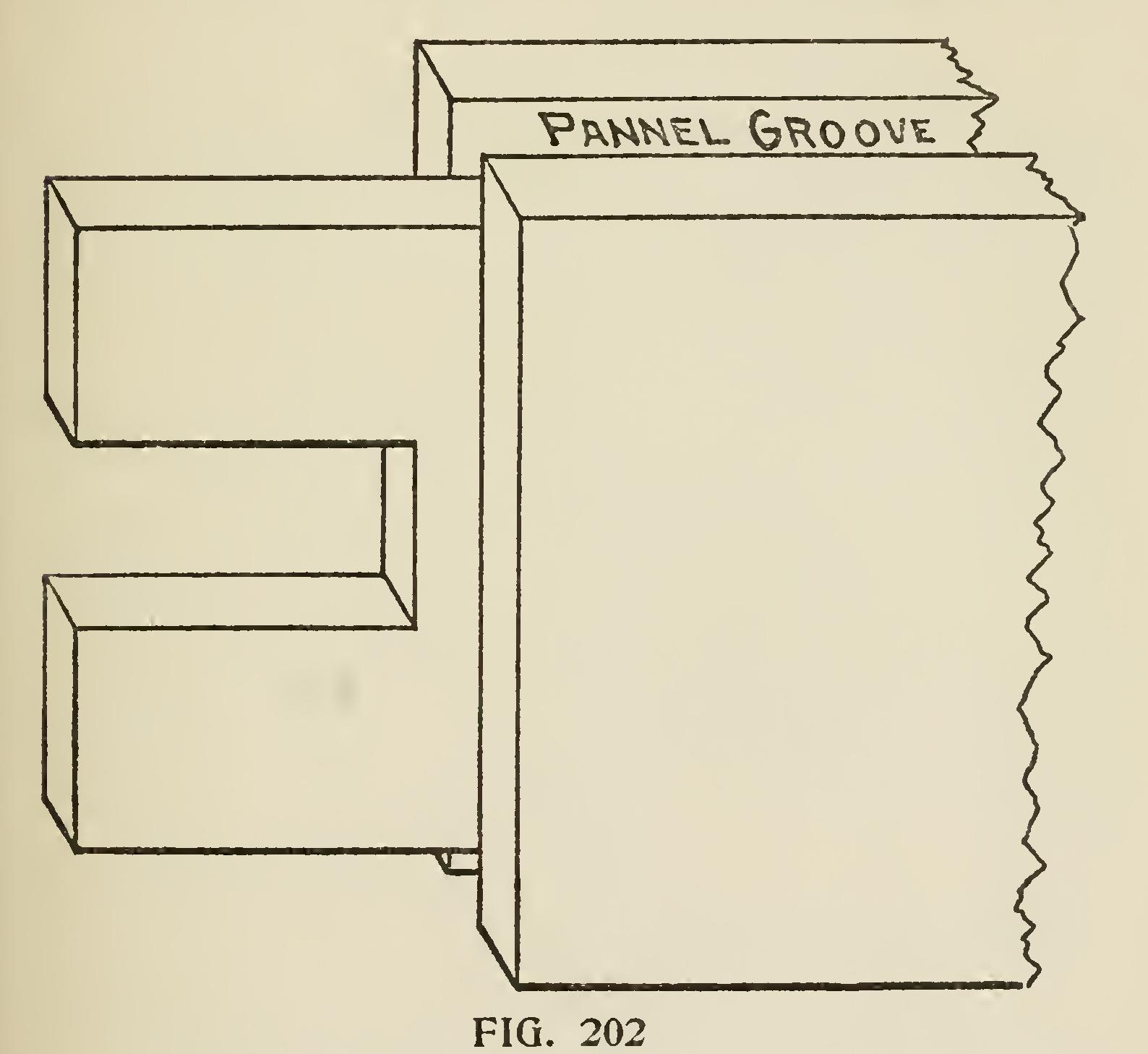

On wide rails, such as lock or middle or bottom rails, this tenon is in two parts in its depth, as in Fig. 202; and where the doors are more than two inches thick, or where the provision has to be made for a mortise lock, which, when let into the center of the style, at lock rail height, completely cuts away a central single tenon, the tenons are double in thickness, and called double tenons, as Fig. 203.

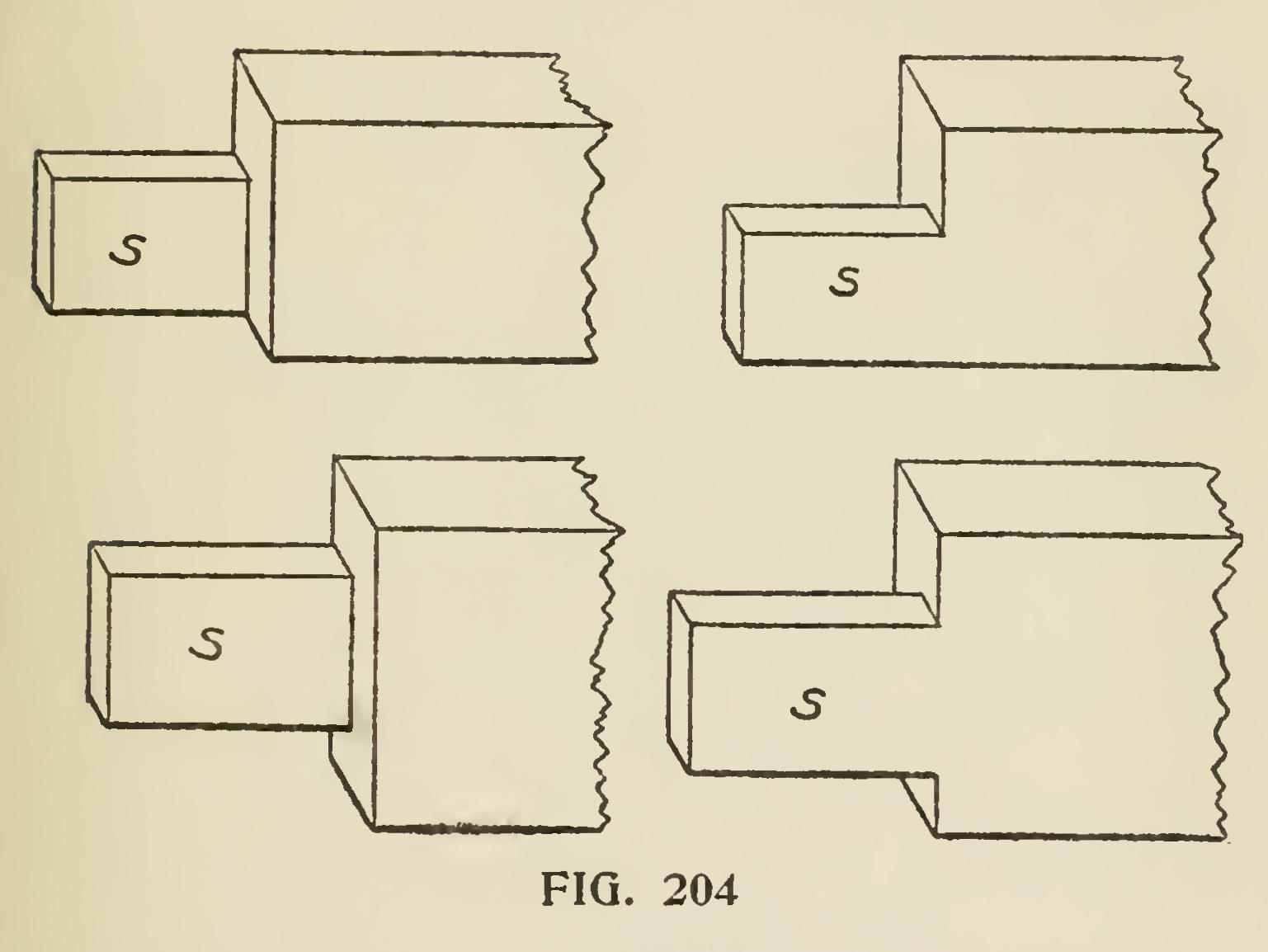

A bare=faced tenon is a tenon with only one shoulder, S, used chiefly in framed ledges and braced doors, where the rails are not so thick as the styles by the thickness of the boarding nailed on the rails between the styles. Fig. 204 illus trates a bare-faced tenon, one view being given of each side.

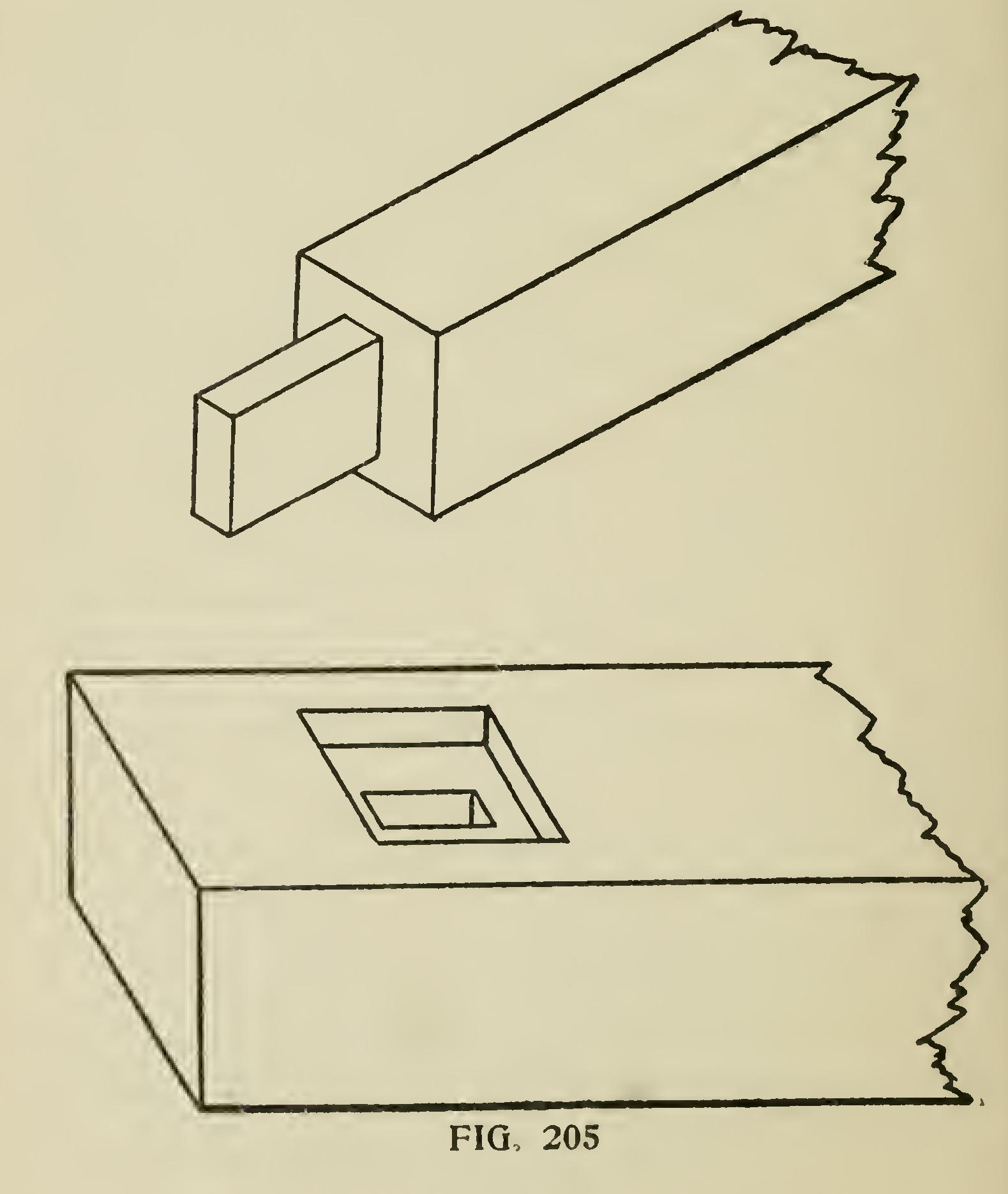

A housed tenon

is one let into a mortise with the section of the stuff let into the mortise to the depth of half an inch, as Fig. 205.

Angle joints.

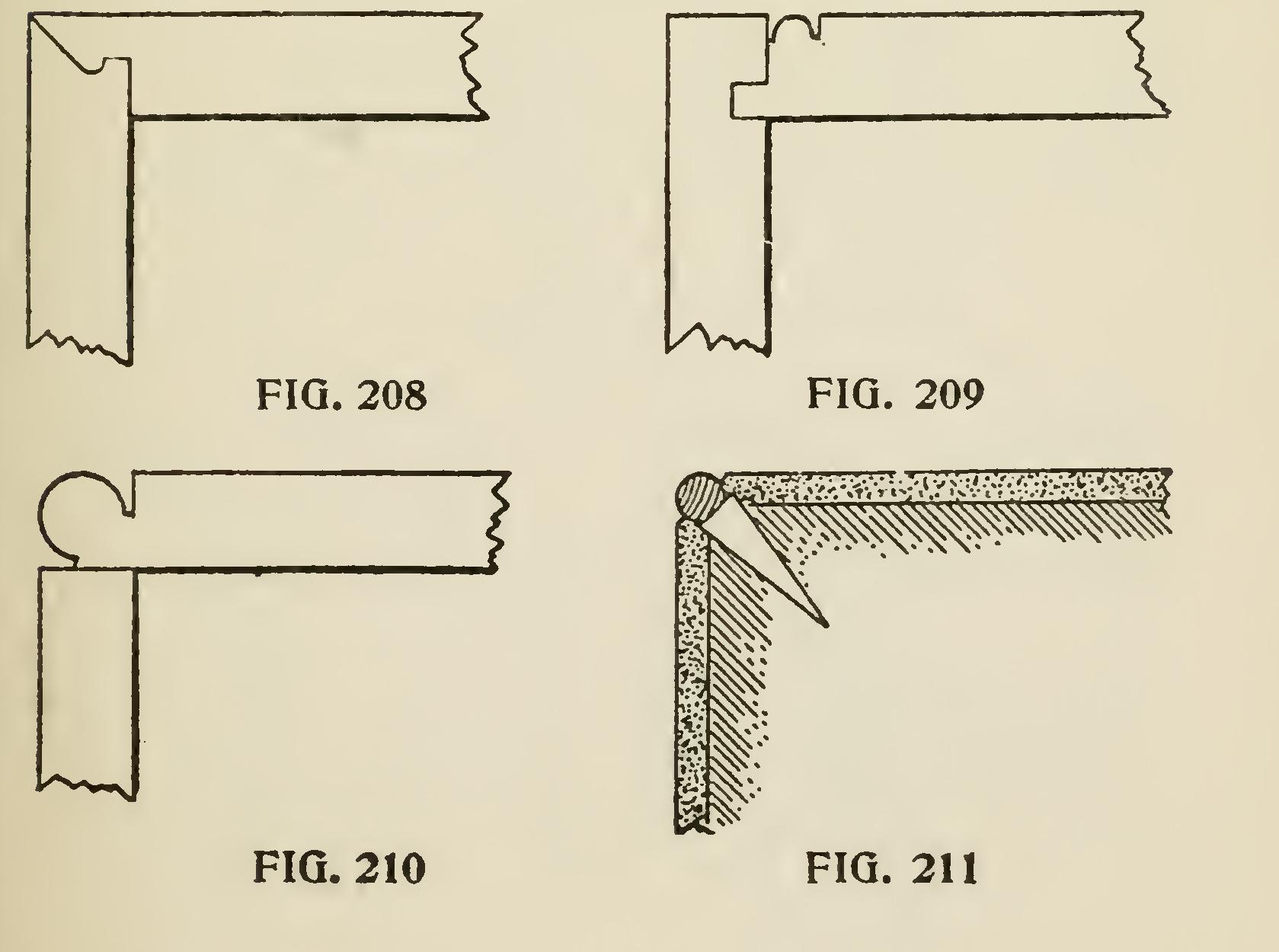

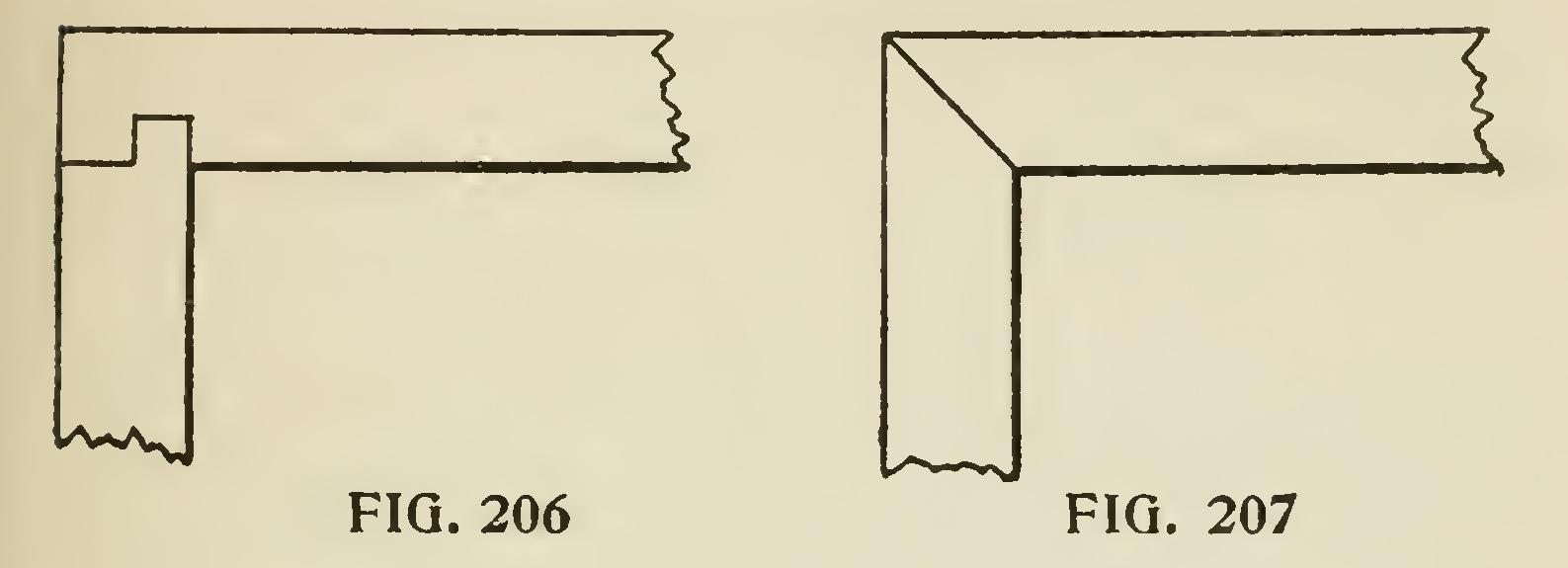

Tongued angles are used for in ternal angles of skirtings, grounds, casings, etc., as Fig. 206.

Mitered angles are made by simply cutting half a right angle alternately off the two pieces, to be joined by nails at an external angle, as Fig. 207.

Mitered and tongued angles,

a combination of the last two, are as Fig. 208, and are only used in best work, at the external angles of dadoes, pi lasters, etc.

Beaded and tongued angles,

illustrated by Fig. 209, are angles or joints of an ornamental as well as necessary character.

Return=beaded angles

are suitable for all exter nal miters where wear and tear would soon fetch the arrises off in soft woods. Fig. 210 shows one on wood framing, casings, etc., and Fig. 211 one as fixed to angles to plastering on wood, brick or stone walls, to which they are fixed by plugs, as will be explained hereafter, this being called a staff bead.

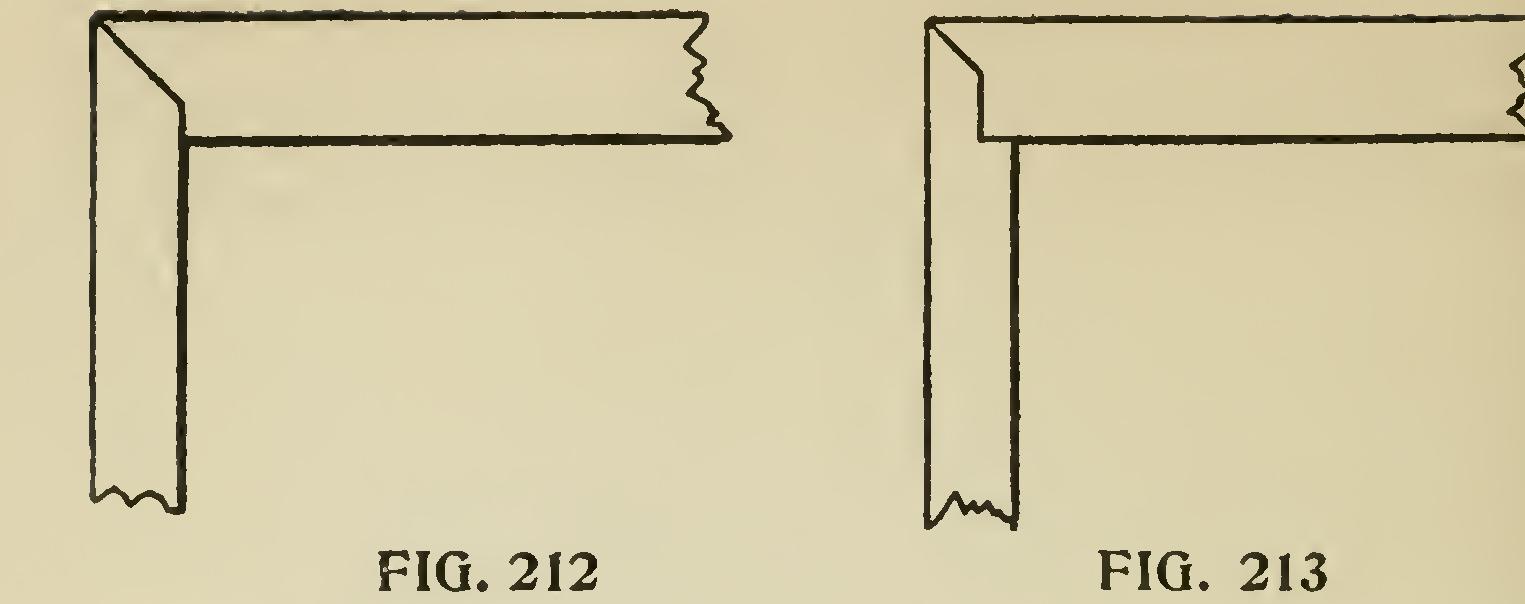

Where the two pieces of framing to be joined are of different widths or thicknesses the "mitered angle" is made as Fig. 212. Another form of very good construction, is as Fig. 213.

Keyed mitered joints

are not often used; but it is as well that the carpenter should know what they are. Fig. 214 is a view of the angle of one, XX being hardwood-slips let into the miters.

Housed joints

are as Fig. 215, by which the whole thickness of the cross-framing is let into the other about half an inch.

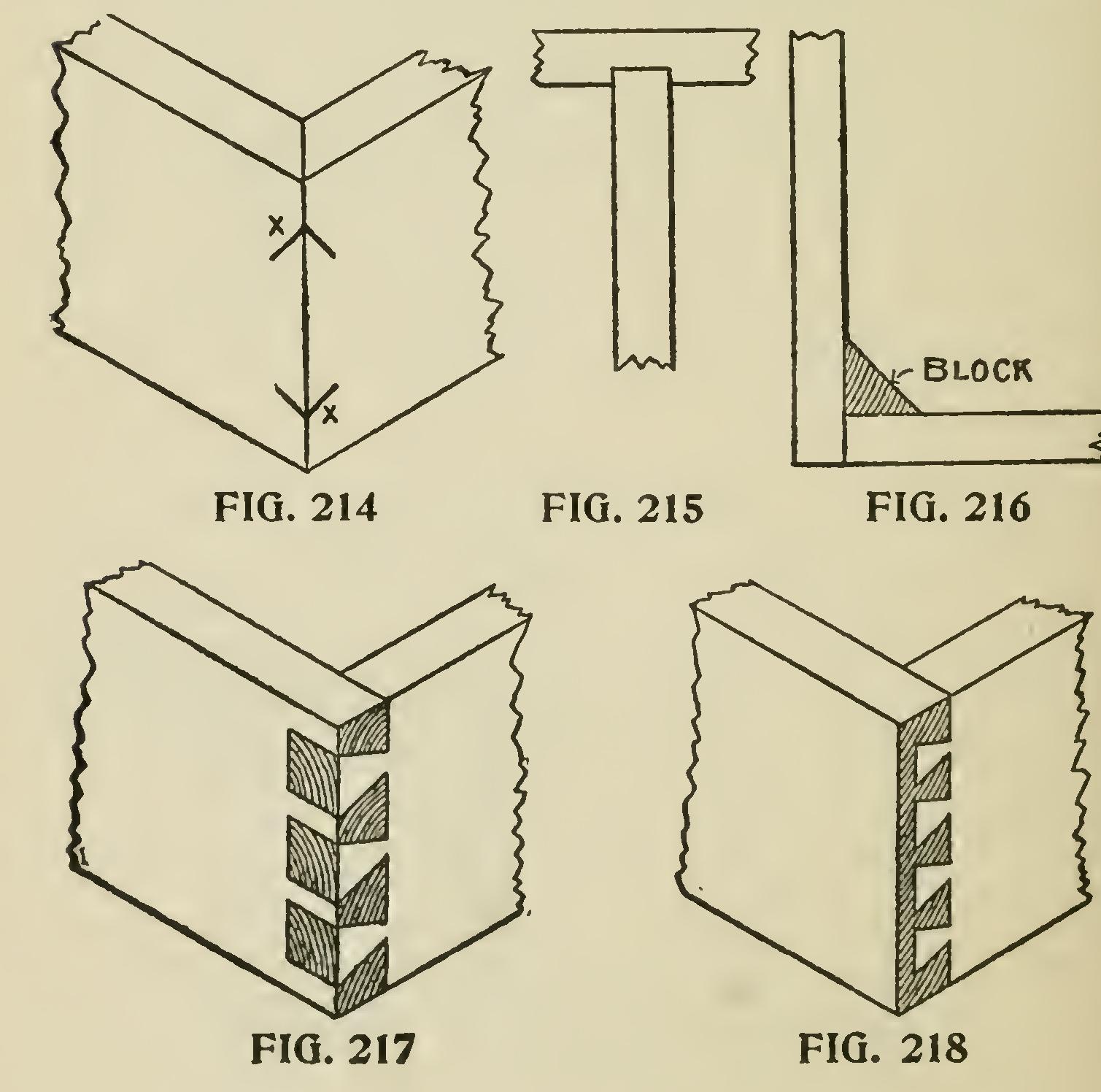

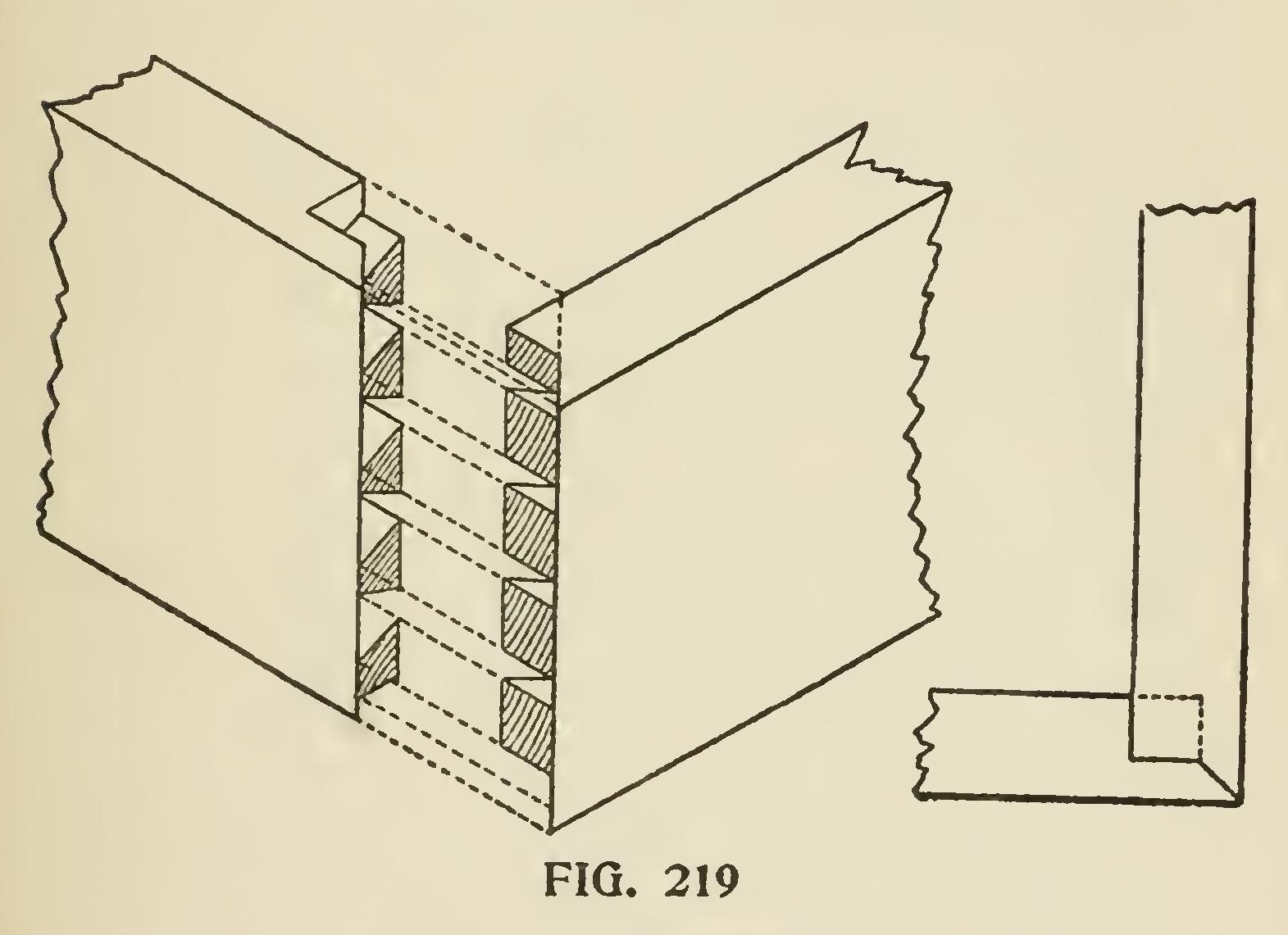

Glued and blocked joints are really butt or lapped joints secured by blocks glued to each piece of wood in the internal angle (Fig. 216). Dovetails.—To make a good dovetail joint re quires considerable skill and care on the part of the operator; but when completed, no other system of joining boards at right angles proves so satisfac tory. There are three kinds: the common, as Fig. 217; the lap, as Fig. 218; and the secret or mitered, the most troublesome of the three, as Fig. 219. It will be seen that they consist of wedge-shaped alternate cuttings out of each piece, the projections of the one fitting the holes on the other.