Placing Radiators

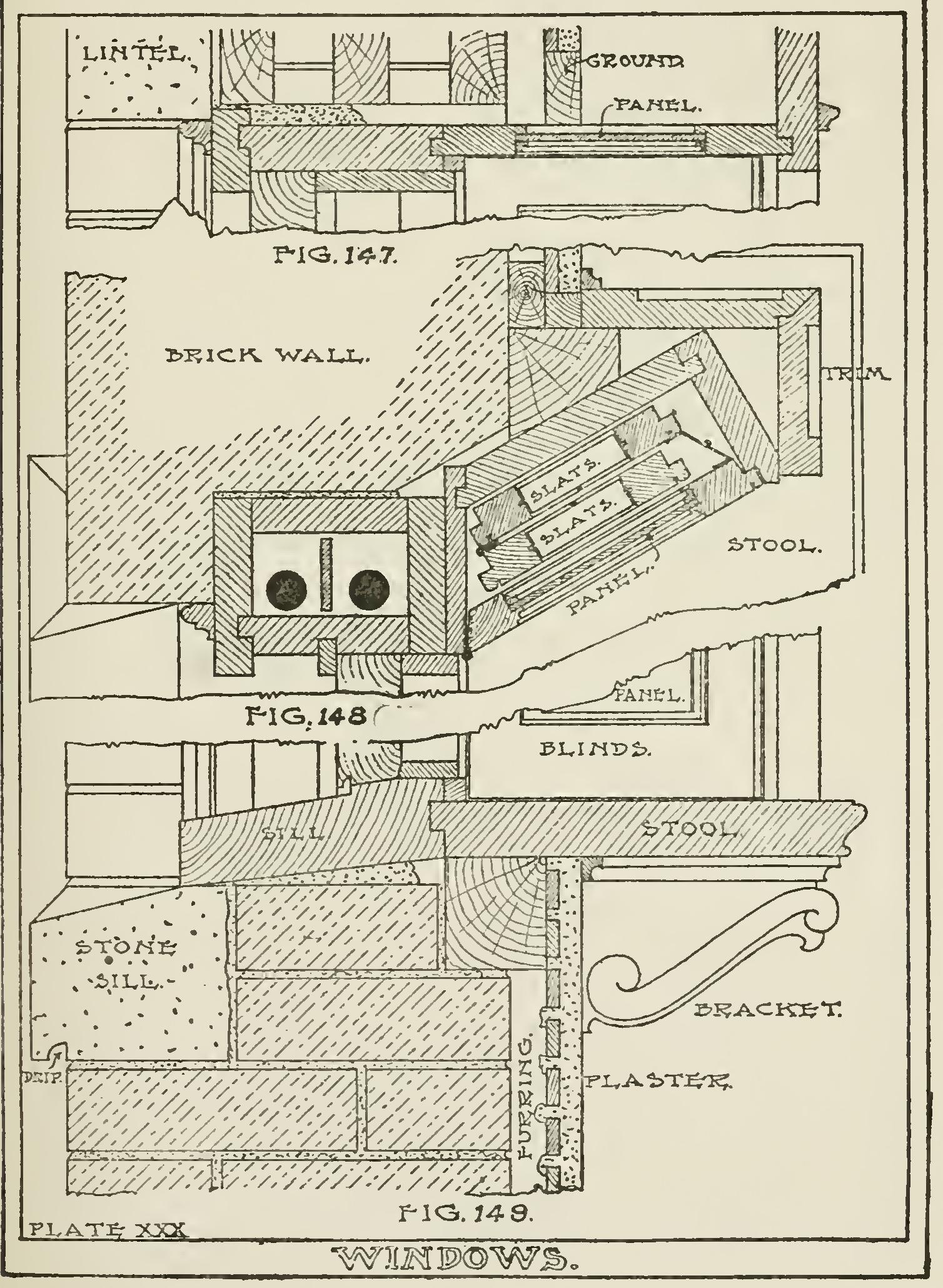

wall, box, frame, window, inside, blinds, head and stool

The inside blinds fold back in a pocket or box, set on a slant, giving the appearance of a deep, paneled, splayed jamb. The first fold of the blinds is paneled and the inside soffit has a panel to correspond with it. The blind box projects into the room, with the trim returned about box to plaster wall. The head is formed like an entab lature, with a crown moulding, a facia and a mould planted on facia. The stool is deep, carried across opening, and returned about box to plaster wall. The stool is supported at each end, under the trim, on carved wood brackets. The joint between the plaster and the underside of the wood stool is covered with a small cored mould which breaks around the wood brackets and returns against wall. The blind box projects into the room, with the trim finish as the other woodwork of the room in which it occurs. This is also true of the inside stop head.

Fig. 147 is a section taken through the head of the window. The panel shown in the inside soffit should be arranged so as to be easily removable in case of splitting or warping. This may be readily done, if constructed as indicated, by removing the small coved wood moulds which hold it in position. These moulds should be fastened to the frame rather than to the panel. In this way the panel is set free so that it may contract or expand with out affecting adjacent work.

Fig. 148 is a section taken through the jamb of the window. The second and third folds of the blinds are provided with rolling slats. The first fold may also be provided with slats, but a panel makes a better appearance and does not catch dust the way the slats would. It will be observed that a special hinge is used on the blinds, which prevents them from catching or sticking in the box. All the blind stiles should be rabeted as shown and should have a head on edge to lessen the promi nence of the joint. The first fold is rabeted over the side of the box which acts as a blind stop. The use of the tongue dividing the weight box is a feature used only in the best grade work.

All interstices and spaces between the window frame and the masonry opening should be made absolutely wind proof. In ordinary work this caulking is done by caulking the spaces with oakum and pointing up with mortar.

Fig. 149 is a section taken through the sill of the window. The wood sill is ploughed for the inside stool. The space under the projecting stool is an excellent place for a radiator. If one is put there, the underside of the stool should be covered with asbestos paper and tinned.

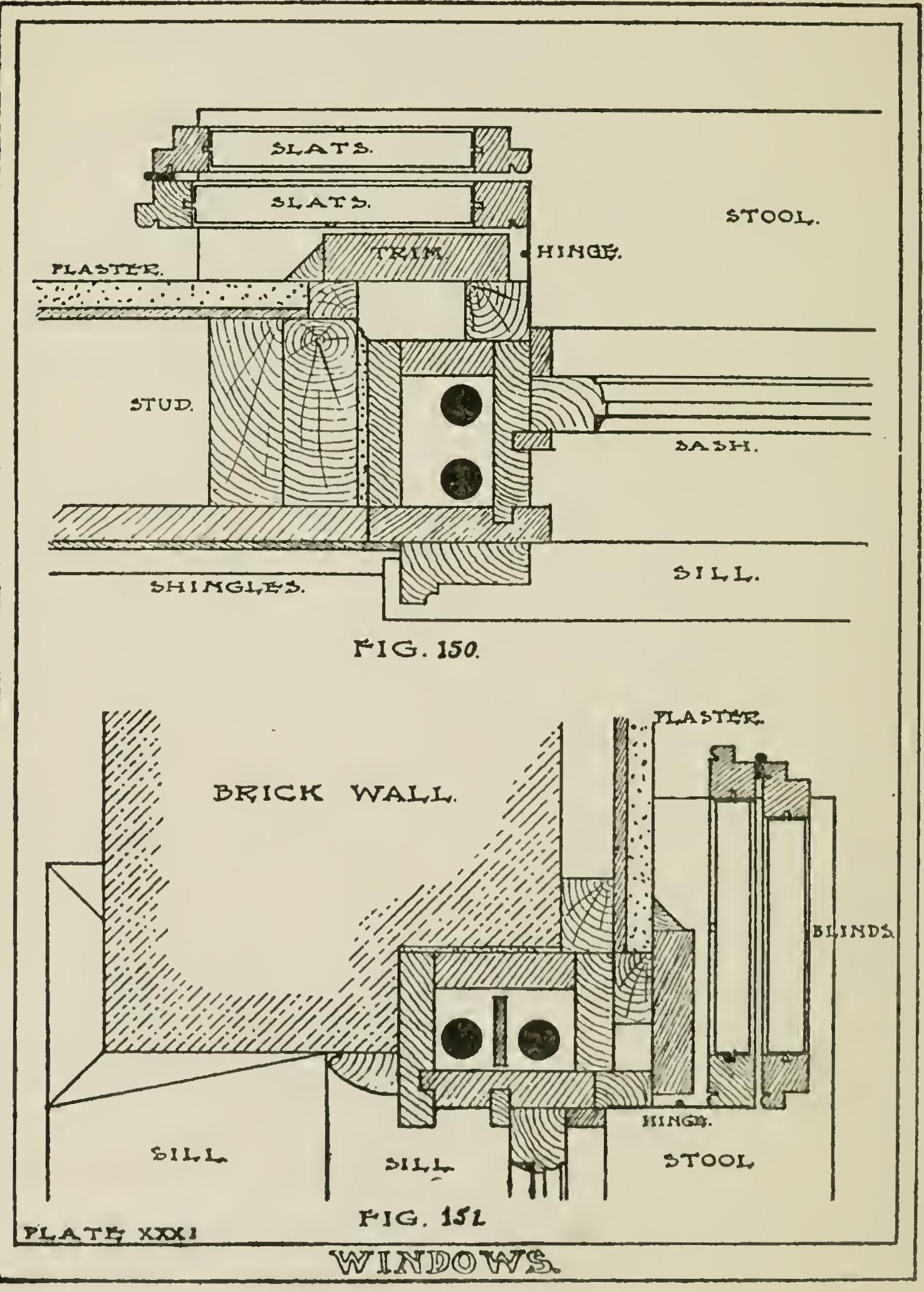

Plate XXXI illustrates windows in both frame and brick walls with inside blinds projecting in the room and folding back flat against wall.

Fig. 150 illustrates the window in the frame wall. This wall is constructed of two-inch by five inch studs set sixteen inches on centers. Studs are doubled about window and door openings and are doubled for the head and sill of each window and the head of each door. One row of herring bone crossbridging is provided between the studs for each story.

The outside of the framework is covered with one-inch by eight-inch matched or ship-lapped hemlock or North Carolina boards. These boards should be laid diagonally in preference to hori zontally as they make a more rigid wall when so laid.

This sheathing is covered with a heavy tarred or rosin sized building paper, well lapped at all joints and well turned in at all corners and angles.

The exposed covering of the exterior of the wall consists of shingles laid five inches to the weather with broken joints and of random widths. Shingles over six inches wide should be split. Shingles should be well nailed with two galvanized nails to each one.

The inside of the wall is plastered on wooden lath and grounds are nailed to the studs to form a gauge for plastering and to give a nailing for the trim. The strip on which the studs are hung should be of the same material and finish as the adjoining trim. The inside stop head also serves the purpose of a blind stop.

The blinds are hung on a special hinge as shown, which permits them to be folded back against the wall, clear of the trim.

This manner of folding the blinds is not quite so good as the methods given in previous pages, as the blinds are rather unsightly and are great dust catchers. This method, however, is resorted to quite frequently owing to lack of space for a blind box.

The window frame is known as a box frame and the space between the box and the stud is either filled with " scratch " mortar or caulked with oakum, so as to make it wind proof.

Fig. 151 shows the same construction adapted to a masonry wall. The window frame is set so as to give an eight-inch reveal. The masonry jamb is rebated for the frame and the joint of the frame with brickwork is covered with a moulded staff bead.

The construction of the heads and sills is about the same as in previous window frame illustrations.