Placing Radiators

sill, sashes, sash, wood, shown, transom, inches, window and rebated

The wall is of brick, thirteen inches thick and the opening is spanned on top by a stone lintel or a brick face arch, back of which is turned rowlock relieving arch over a wood lintel or center.

The sill is of stone cut with a wash and has raised lugs or stools to receive the brick impost or jamb. The sill is usually two brick corners in height, eight inches longer than the width of the brick window opening, and is of a proper depth to extend under the wood sill at least two inches. The projecting portion of sill has a water nose or drip cut on the underside. The sill when first set should have mortar placed only under the ends which receive the brick imposts. The portion of the sill spanning the opening should be kept free from mortar until the building is topped out, as the settlement, which inevitably occurs, would be likely to crack the sill if bedded in mortar under the center. The open joint, however, should be well pointed up after the settlement has taken place.

Construction of the casement window opening outward. We illustrate first a double casement in a frame wall, with the sashes hinged at the side and opening outward, and with a stationary transom overhead.

The wall is constructed of two by four-inch studs, placed sixteen inches on centers and doubled for jambs, heads and sills of openings. It is covered on the outside with matched sheathing boards, heavy tarred felt and random with shingles. The inside is wood lathed and plastered three coats.

The frame is moulded and rebated as shown, and one and three-quarter inches thick. The sashes require heavier stiles and rails than the sashes for double hung windows do and in cases where it is desired that as little wood as possible shows, the sashes are made of cherry or other suitable hardwood and are reduced in size. The stiles and bottom rail of sashes, in addition to being rebated, have grooves cut in same as shown, so that any water which may beat its way in will run out through the grooves.

The sashes are shown glazed with double thick glass, bedded in putty, sprigged, and back-puttied. For large sashes or where plate glass is used wood beads or moldings are better than the putty for securing the glass in place.

The sill is rebated for the lower rail of sash and is ploughed for stool and shingles. All spaces about the frames are calked with oakum and pointed with "scratch" mortar.

The trim or architrave is molded and formed out of seven-eighths inch stuff, is blocked on the back and is provided with a back band and a neat wall mold. This wall mold being small may be bent to fit the slight unevenness of the plaster. The inside stop bead should be of the same material as the trim and similarly finished. In the better

class of buildings the stop bead is secured in place by means of round head brass or bronze screws set in a sunken socket of brass or bronze, instead of being nailed in place. By this means the stop bead is easily removed without marring the wood or var nish or may be slightly shifted in or out, if the sash binds or rattles, by merely loosening the screw a little. Stop beads should never be less than one and three-quarter inches wide so that window shades may be set on same.

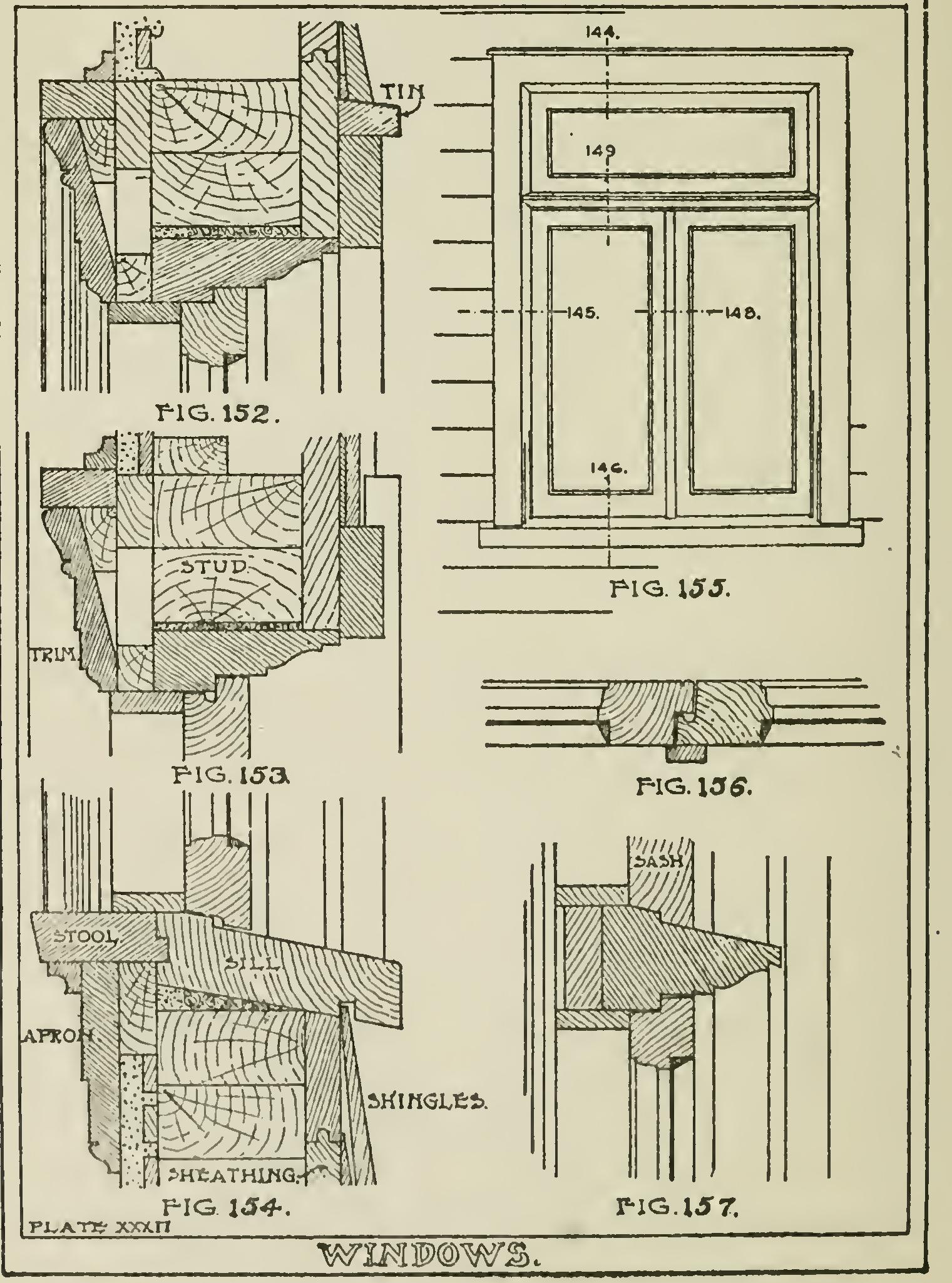

Fig. 152 is a section taken through the head of the window. The top of the outside casing is covered with tin turned down over the outer edge and neatly tacked, and extending up under the shingles or other exterior covering about six inches. A little wood fillet is placed over the cap as shown, to give the first course of shingles the required tilt.

Fig. 153 is a section taken through the jamb of the window. The block or furring strip which is shown nailed on to the side of the stud, is necessary as a nailing for the lath which cannot obtain a direct bearing and nailing on the stud, owing to the position of the ground to which the inside architrave is nailed.

Fig. 154 is a section taken through the sill of the window. As an additional precaution against rain, beating in under the lower rail of sash a molded water nose might be let into the rail on the outside or a groove might be cut on the underside of the rail near its outer edge.

Fig. 155 is an exterior elevation of the window and the dotted lines with the numbers indicate the cuts from which the sections illustrated are taken.

the meeting stiles of the sash. The standing leaf is rebated and the inner edge is beaded. The other leaf is rebated and grooved and has a flat band or astragal planted on the outside to cover the joint of the meeting stiles. The groove in the stile catches any rain-water which may beat in, and carries it down to the sill. Note that there is a slight bevel to the joint of the meeting stiles to allow for the play of the sashes.

Fig. 157 is a section taken through the transom bar. The upper or transom sash is stationary and is rebated over the transom bar and the joint is made in whitelead. When the transom sash is hinged or pivoted a water nose or groove is usually provided on the lower rail of sash. The transom bar should have about the same pitch as the win dow sill so as to properly cast off the water, and the outer edge should have an undercut as shown to prevent dripping water from running down under head of frame and in over top of sash. The inside surface of the transom bar is paneled as shown and inside stop bead follows across same.