Straps Joints

bolts, joint, method, fig, framing, bearing and strength

JOINTS, STRAPS, AND OTHERFASTENINGS We have already described the principal joints used in ordinary framing. There are also a considerable number of joints in which advan tage is taken of special mechanical aids, either in the way of cutting the joint so as to give a special arrangement of bearing surfaces, or by special devices such as straps, bolts, etc., to strengthen the joint.

Joints should be formed in such a manner that the bearing parts may have the greatest possible amount of effective surface. For should that part of the joint which receives the strain be narrow and thin, it will indent itself into the pieces to which it is joined or become crippled by the strain, producing in either case a change in the form of the framing.

The effect of the shrinkage and expansion of timber should also be considered in the con struction of joints. On account of the shrinkage of timber, dovetail joints should seldom be used, as the smallest shrinking allows the joint to draw out of its place; they can be used with suc cess only when the shrinkages of the parts coun teract each other—a case which seldom happens in carpentry, though very common in ioinery and cabinet-making.

Joints should also be formed so that the con traction or expansion may not have a tendency to split any part of the framing. The force of con traction or expansion is capable of producing astonishing effects where the pieces are confined, which may sometimes be observed where framing has been wedged too tightly together in improper directions. The powerful effect of expanding tim ber is well know to quarrymen, as they sometimes use its force to break up large stones.

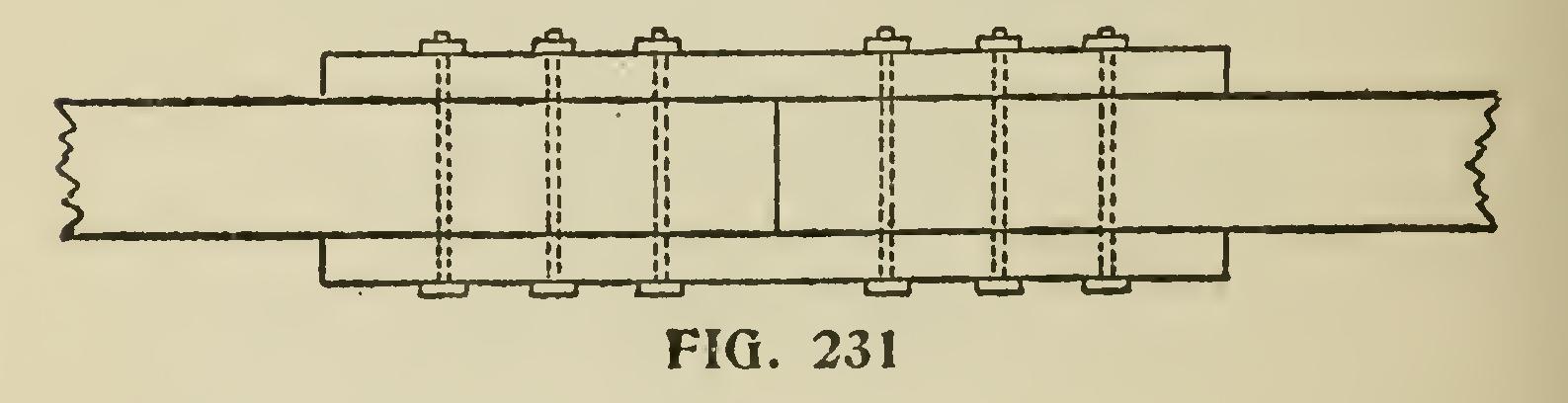

In forming joints the object to be attained should always be kept in view, as that which is excellent for one purpose may be the worst pos sible for another. With this consideration the subject will be treated under separate headings as follows : Lengthening Ties.—The simplest and perhaps the best method of lengthening a beam is to abut the ends together, and place a piece on each side ; these, when firmly bolted together, form a strong and simple connection. Such a method of length ening a tie is shown by Fig. 231, and is what ship carpenters call fishing a beam. It is obvious,

however, that the strength in this case depends on the bolts, and the lateral adhesion and friction produced by screwing the parts tightly together.

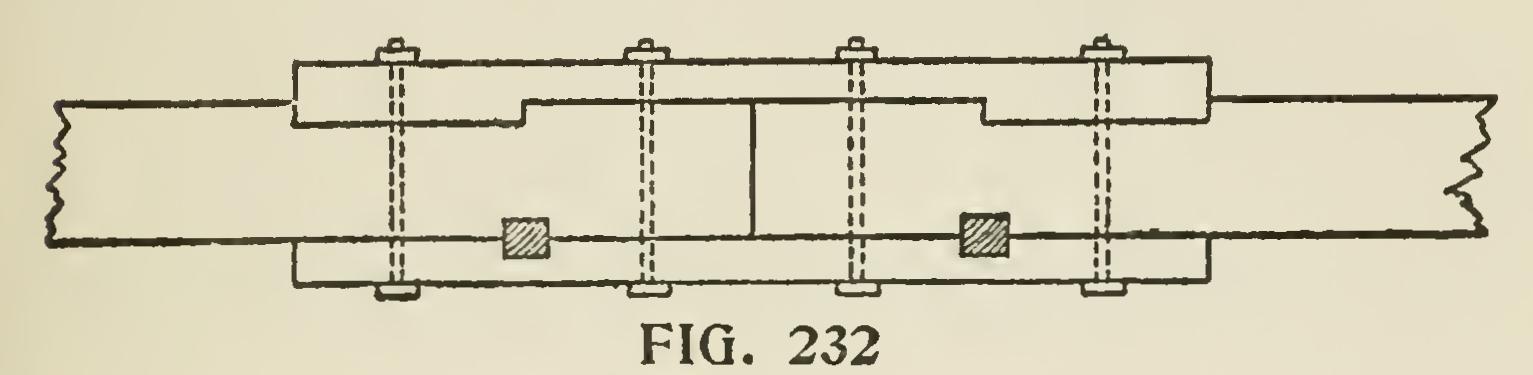

The dependence on the bolts may be lessened by indenting the parts together, as shown by the upper side of Fig. 232 ; or by putting keys in the joint, as shown by the lower side of the same figure; but the strength of the beam will be decreased in proportion to the depth of the indents.

The only reasons for not depending wholly on bolts are, that should the parts shrink ever so little, the bolts lose a great part of their effect ; and the smallness of the bolts renders them liable to press into the timber, and thus to suffer the joint to yield.

The most usual method of joining beams is that called scarfing, where the two pieces are joined so as to preserve the same breadth and depth through out ; and wherever neatness is preferable to strength, this method should be adopted.

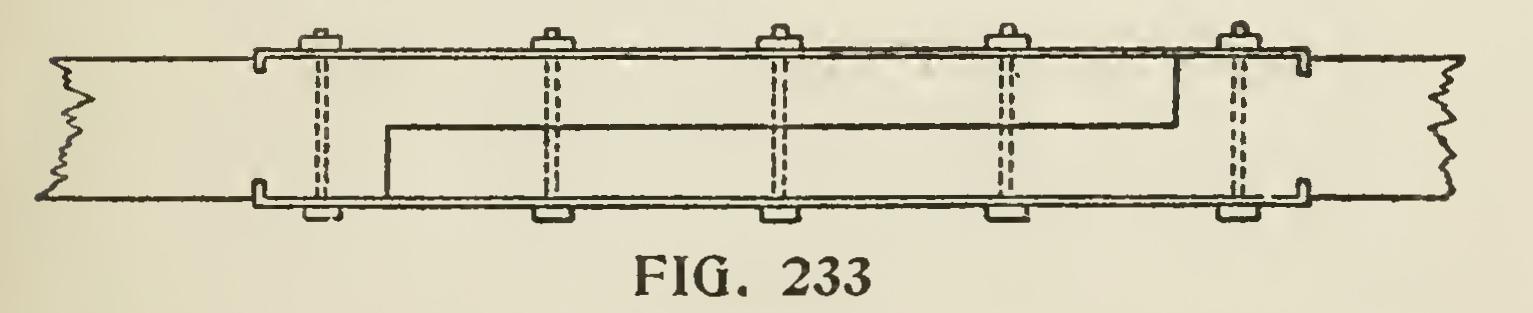

Fig. 233 is the most simple method of strafing; it depends wholly on the bolts, and in this and like cases it is best to put a continued plate of iron on each side to receive the heads of the bolts. The ends of the plates may be bent and let into the beams.

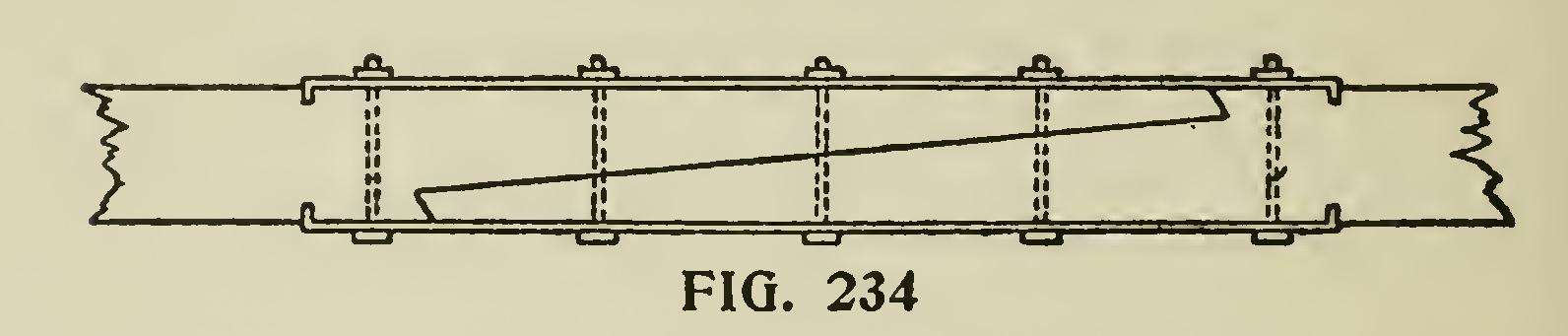

Fig. 234 is another very common method, but not so good a combination, as the bolts do not press the surfaces in a perpendicular and an oblique pressure, such as would be likely to take place in this example must have some tendency to separate the joint, and it has no advantage in other respects.

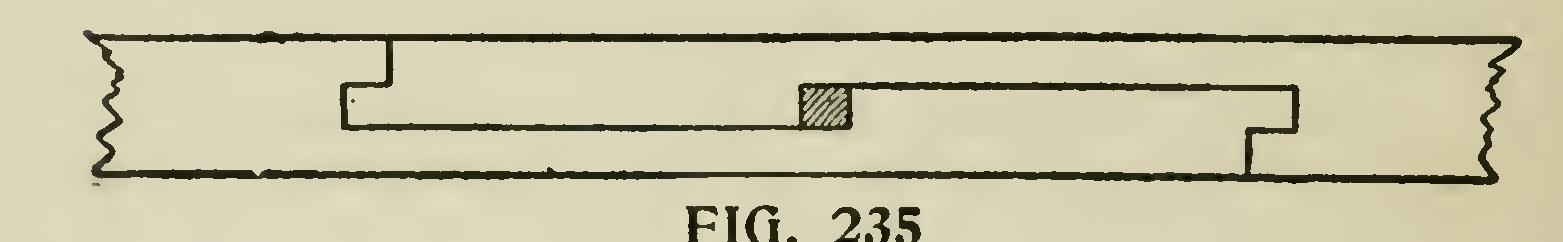

Fig. 235 is a joint where bolts would not be absolutely necessary, but it is clear that the strength would not be quite so great as half that of an entire piece the key, or double wedge in the center of the joint, should only be driven so as to bring the parts to their proper bearing, as it would be better to omit it altogether than to drive it so as to produce any considerable strain on the joint. It is not necessary that there should be a key, except when bolts are to be added, and then it is desirable to bring the joints to a bearing before the bolts are put in. The addition of bolts and straps, however, makes this an excellent scarf.