Windows in Brick Walls

inches, lintel, masonry, blinds, wall and sill

The sash are shown one and three-quarters inches thick and glazed with plate glass, bedded in putty and held in place with wood beads.

Metal lath is nailed to the timber lintel to afford a clinch for plaster. This lath will also be re quired over any recesses or pipe chases in masonry walls.

Plate XXVI illustrates another method of con structing a double hung window frame in a masonry wall. The opening is spanned on the outside by a moulded stone lintel and the inner eight inches of the wall is carried on an iron lintel (Fig. 130). An iron lintel is usually provided when it is not convenient to turn a rowlock reliev ing arch over a timber lintel, as in the case of floor beams bearing over opening, so close to window head as to make it impossible to turn an arch underneath them. They are also used over wide openings in preference to arches.

Fig. 131 is a section through the jamb of win dow. Stone quoins of various widths and heights are provided for masonry jambs.

Fig. 132 is a sill section and shows a moulded drip on bottom rail of sash.

Figs. 133-135 are exterior elevations.

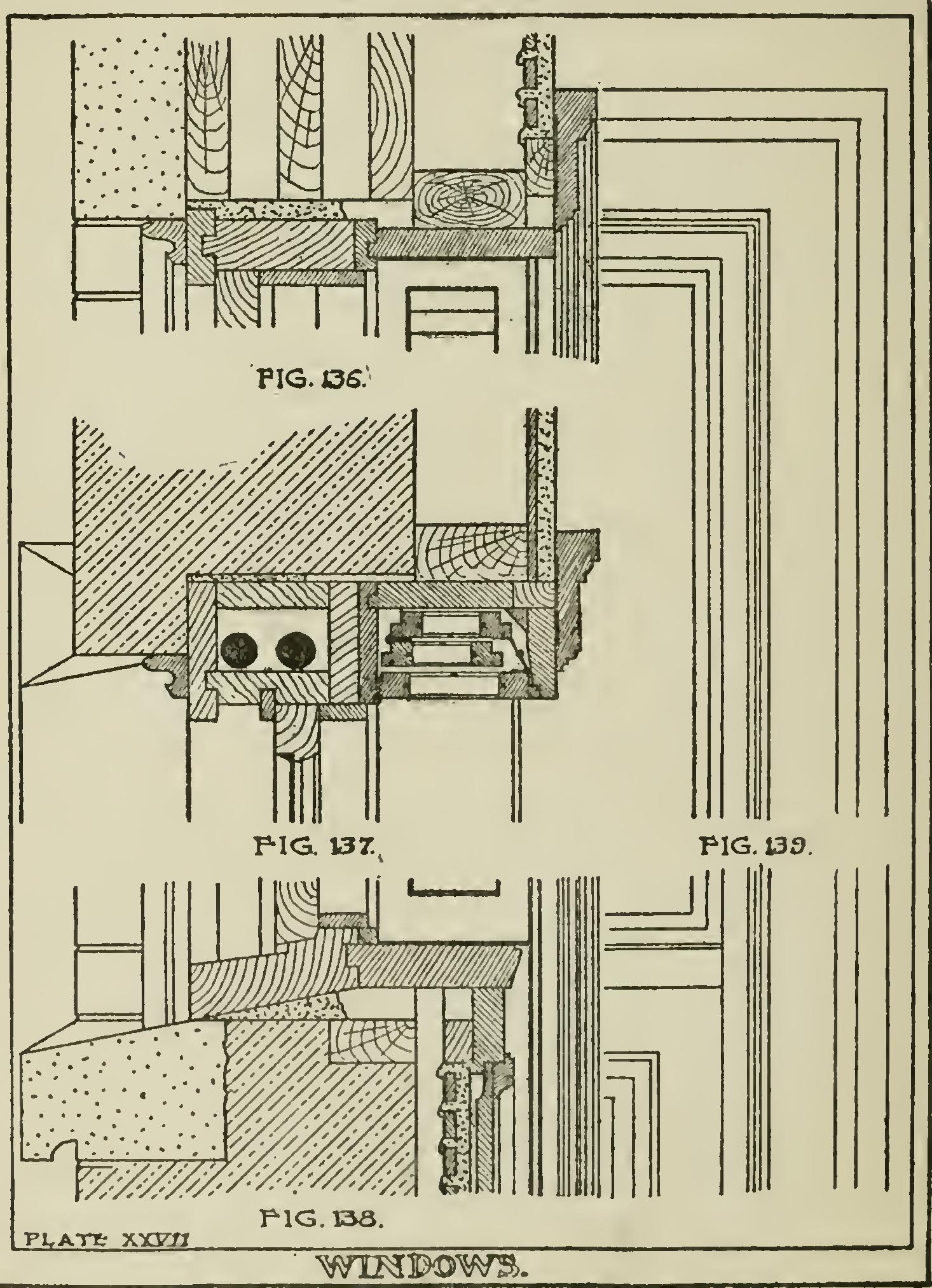

The use of inside blinds on double hung windows in masonry walls is considered. Plate XXVII is a double hung window frame in a thirteen-inch brick wall. A stone lintel is provided on the outside over the opening ; in depth it should equal the height of four or five courses of brick; its thickness should be not less than the brick reveal, Lnd it should have a bearing of about four inches on each brick jamb so as to take up with the brick joints. The opening is spanned on the inside with a timber lintel or center made up of three pieces of two-inch stuff, cut to the required curve, with cross strips across top called lags. On top of the wood center or lintel a rowlock arch is turned. Rowlock arches are usually made with one rowlock for each eighteen inches or fraction thereof in the width of masonry opening. The rise is usually made one inch for every eighteen inches of width of opening.

The sill of the masonry opening is of stone, the thickness of two courses of brick, of a depth that will overhang the wall on the outside about one and one-half or two inches, and will extend under the wooden sill not less than two inches. The sill

is cut with a wash and lugs and on the underside of projecting part has an undercut or water nose.

The wall is furred on the inside with two by four-inch stuff, placed sixteen inches on centers, so as to give the required extra width for blind boxes.

The calking of interstices at head sill and jambs of frame is shown of "scratch" mortar, but in the best grade of work is usually of oakum hand calked, so as to make the construc tion absolutely wind proof.

Fig. 136 is a section showing the usual construc tion at the window head. The wide soffit may be paneled if desired. A moulded staff bead should always be used to cover the joint at the intersection of the frame with the masonry, on the outside.

The lath, plaster and grounds are applied to the furring in the usual manner. The trim is mitred and tongued or doweled together at the head, a feature employed only where expense is not an all important consideration.

Fig. 137 is a section through the jamb and shows the construction of the blind box and the method of folding blinds. It will be observed that a special hinge is used on blinds, which prevents them from catching or sticking in the box. All the woodwork of box, which would be exposed to view when the blinds are closed, should be made of the same material as, and should conform to, the finish of the balance of the room. All the blind stiles should be rebated as shown.

The blinds are all shown with rolling slats, but frequently the blind fold, which is exposed to view when blinds are folded back in the pocket, is made paneled instead of with slats, so as to give the effect of a paneled window jamb.

The inside stop bead should be made at least one and three-fourth inches wide, or better two inches wide, so as to give plenty of space for shades between blinds and sashes.

The use of a strip dividing the weight box would be an improvement.