Windows in Brick Walls

window, arch, wall, fig, section and center

WINDOWS IN BRICK WALLS We will start a consideration of double hung sash frames in brick walls.

Plate XXIII illustrates a well constructed frame in a thirteen-inch wall; the window finishing with an arch on the outside and a square head on the inside.

Fig. 119 is a section through the window head at the center line. The opening is spanned on the outside by a segmental arch "B" of face brick, rubbed to the required shape and laid on a tem porary wood center. This center should not be "stuck" until the mortar has thoroughly set.

The inner eight inches is spanned by a perma nent wood center "C, " usually constructed of two inch spruce and made of sufficient length to give a bearing of four inches on the wall on each side of the window opening. On top of this center, a two-rowlock relieving arch "A," is turned.

The wall is furred on the inside as indicated at "E, " and is then lathed and plastered; grounds being set as shown.

This furring of late is frequently omitted and the plaster applied on the brick wall itself, after it has been made impervious to water by a heavy coat of one of the many waterproof paints now on the market. This paint prevents the dampness, which penetrates the wall, from discoloring the plaster work.

Fig. 120 is a section through the jamb of th beams for the support of the floor joists which bear directly over the opening. These iron beams are necessary when there is not sufficient space be tween the window head and the under side of the floor joists, to turn a brick relieving arch on top of a timber lintel.

A piece of two by four stuff is bolted to the web of the inner iron beam as shown, to secure a nailing for the furring.

A two and one-half-inch by a three and one half-inch angle iron is shown under the face arch, and is provided so as to prevent any settlement of the arch. Without some support of this kind, flat arches are very likely to sag in the center, causing a very unsightly appearance.

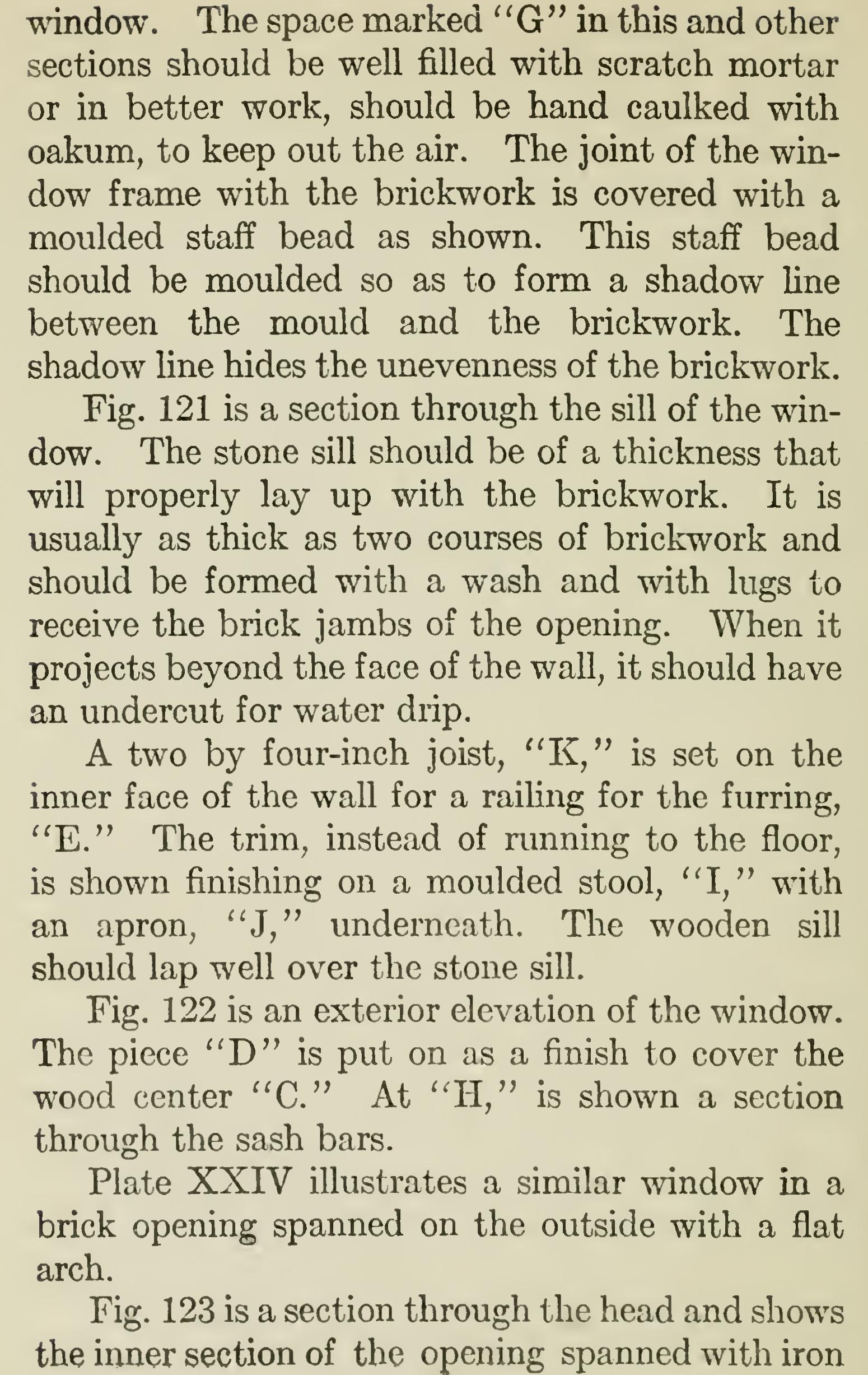

Fig. 124 is a section through the jamb.

Fig. 125 is a section through the sill. It shows the trim running to the floor and the space under window finished with a panel back.

Fig. 126 is an exterior elevation of the window.

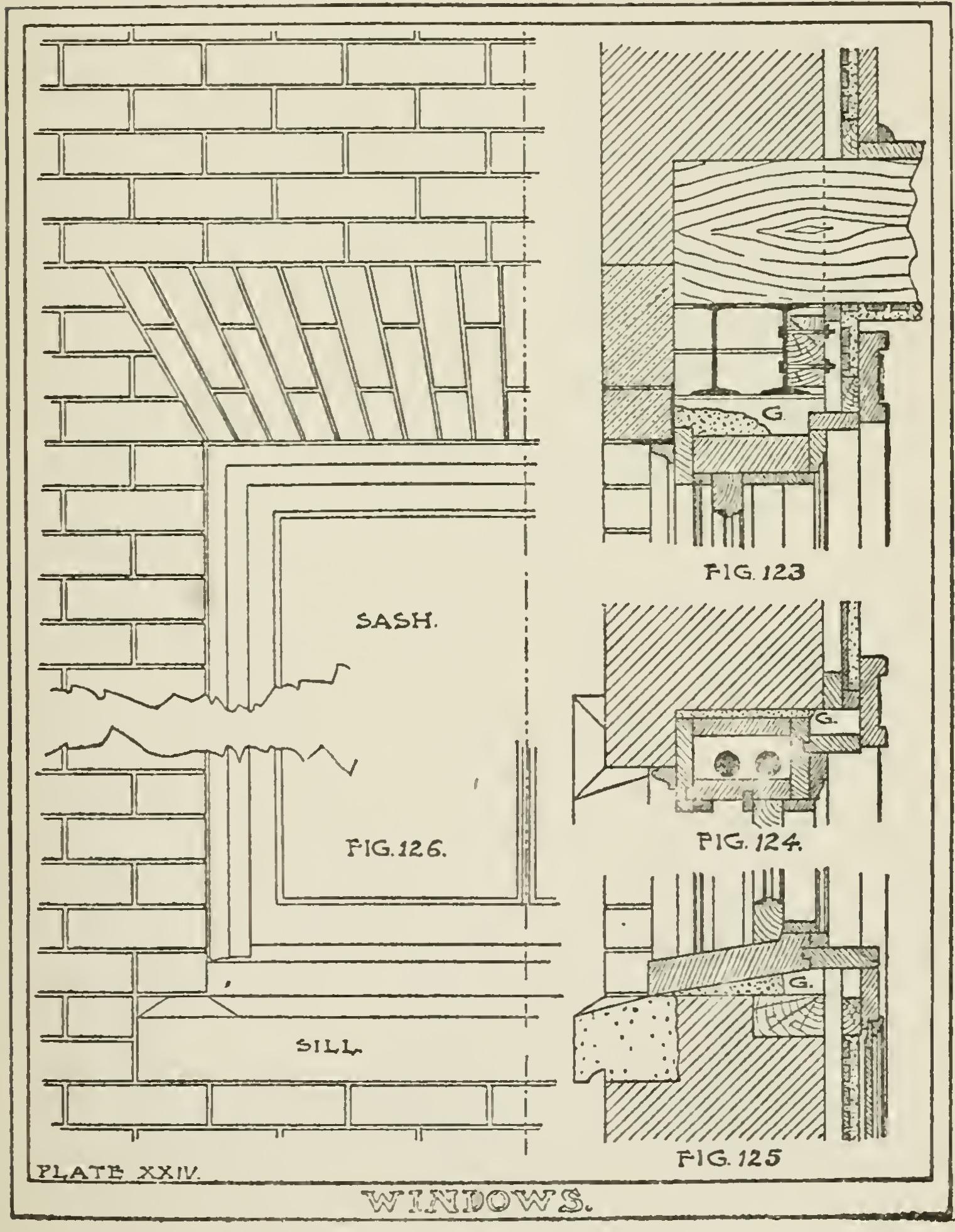

Continuing the consideration of window con struction, we illustrate in Plate XXV, a double hung sash window in an eighteen-inch brick wall.

Fig. 127 is a section through the window head. The opening is spanned on the outside with an arch of stone and on the inside a timber lintel is provided, and a rowlock relieving arch turned on top of same. Relieving arches are usually con structed with one rowlock to each eighteen inches or fraction thereof in the width of the brick open ing. The timber lintel is constructed with two or three centers of two-inch stuff, cut to the required curvature. On top of these centers are nailed narrow wood strips called lags.

Fig. 128 is a section through the window jamb. The calking shown in this and other sections is to keep out penetrating winds. This calking is commonly done by filling around all openings, as shown, with scratch mortar, but in the highest grade work is done by hand-calking all the spaces around frame with oakum.

It will be noticed that furring and lathing of inside of walls is omitted, and the plaster applied directly to brickwork. When this is done, the wall should be thoroughly coated with a water proof paint so as to make it absolutely impervious to moisture and dampness, which would discolor the finished plaster work. There are several of these paints now on the market, and, when prop erly applied, make a wall absolutely damp-resist ing. Before the paint is applied, the mortar joints should be raked out enough to give a clinch for the plaster, as shown in Fig. 129.

This section is taken through the window sill, and its principal feature is the joint of the wood and stone sills. This joint is made water-tight by means of a galvanized iron bar or tongue which is let into a slot on the underside of the wood sill and lead-calked into a corresponding reglet in the stone sill. The stone sill is cut with wash and lugs on top, and with a water drip on the lower edge.