Windows in Frame Walls

window, wall, fig, sliding and brick

Fig. 108 shows a double-glazed sash for exposed locations. The principal objection to their use is that dust will sooner or later get between the sheets of glass, which, with the sweating in cold weather, will soil and streak the glass where it is inaccessible for cleaning.

Fig 109 shows a window frame constructed for the use of heavy sashes the use of four-inch by five inch studs and the placing of the outside casing over the sheathing boards gives the required width to the pulley stile.

We will conclude the study of double hung win dows in frame walls ; illustrating in Plate XXI a window with inside sliding blinds and in Plate XXII a double hung window in a brick veneer wall.

In Plate XXI we have shown the inside blinds sliding in grooves on the window jambs, and, when not in use, sliding down in a pocket (Fig. 112) behind a moulded panel back. The pocket is covered by a hinged stool "A, " which raises up as indicated by the dotted lines when it is desired to use the blinds.

Rather than have the sliding grooves and blinds project in the room, we have made the wall thicker by the use of three by six-inch studs, with the exception of that portion of wall under window frame where we have used two two by four-inch studs. When the wall is not made thick enough to take up the extra thickness of blind box and Aides, the whole window is made to project in the room, causing a more or less unsightly appearance. The window frame itself is constructed in pretty much the usual manner, the exceptions being the extra width of window head and pulley stile caused by thickness of wall and the omission of the inside stop beads, in place of which we have the sliding grooves marked "S. G."

The plastering behind the blind box should not be omitted. The scratch and brown coats, how ever, are sufficient. All spaces around window frame should be well filled up with scratch mortar.

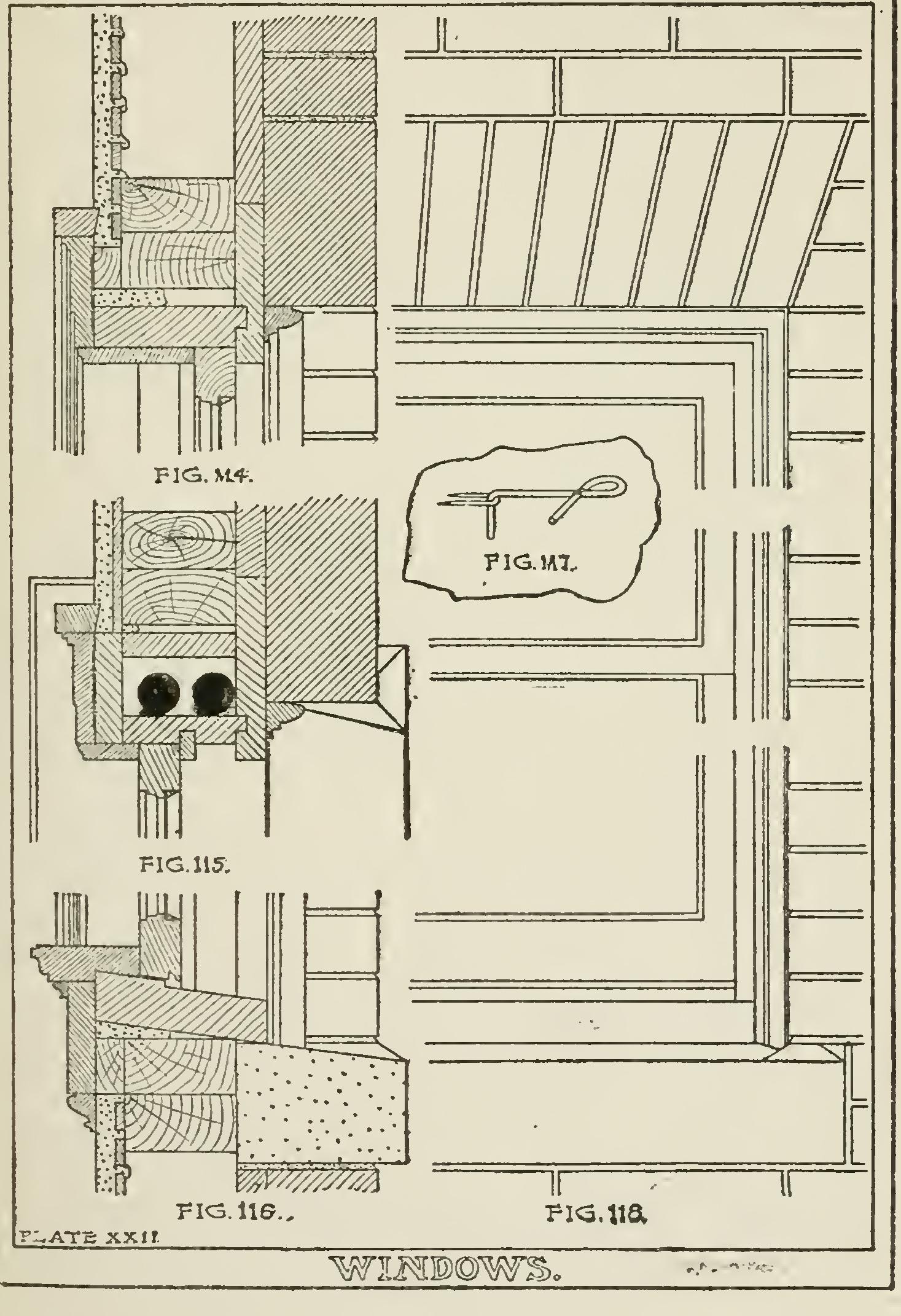

In Plate XXII the wall is constructed of two by four-inch studs, doubled at openings ; plastered on the inside ; sheathed diagonally on the outside with matched boards; then covered with water proof sheathing paper; and then with four inches of brickwork. The veneer of brick should be tied to the frame wall every five courses, opposite every stud, with patent veneer ties, shown in Fig. 11 7. The tie is made of one-eighth-inch galvanized steel wire, and is far superior to the iron nails frequently used.

Brick veneer construction for exterior walls is largely used in many sections of the country, and seems constantly growing in favor.

The window frame is constructed in the usual manner, with a moulded staff bead to cover the joint of brickwork and window frame.

Fig. 114 is a section through the window head. Fig. 115 is a section through the jamb. Fig. 116 is a section through the still, and shows the wood sill lapping over the stone sill. The stone sill is made the thickness of two courses of brick, four inches longer than the width of brick opening, and six inches deep. It is made with a wash and with lugs at each end, projects one inch beyond the face of the wall, and extends back to the studding, over the sheathing. Fig. 118 is an exterior eleva tion of the window.