Classes of Tension Members 50

square, inches, inch, pounds, net and plate

Diameter of head, inches, being to the nearest half-inch.

(2) The stress is 48,000 pounds. If the tension member is to be one plate, what is the size, the allowable unit-stress being 15,000 pounds per square inch? Required net area = 48,000 =15,000 = 3.2 square inches. By (C 247) it is seen that a inch by plate with an area of 3.25 square inches, is the nearest. This is the net area. Since the plate is attached by rivets, there must be an increase in width equal to the diameter of the rivet used times the number which could be cut by a line drawn across the member. Sup pose two rivets were cut. The width would then be inches. An inch plate would be used. Note that in this case the plate may be thinner than one-sixth the width. It is because no heads are forged on it as in the case of eye-bars.

(3) If the total stress and unit-stress are as above, design an angle to take the stress, the rivets being in diameter.

The required area will be the same, 3.2 square inches. An angle (C 113) by 3 by will be tried.

Gross area = 4.00 square inches Out for one rivet in. = 0.69 square inch Net area = square inches The inch is multiplied by 1 (inch) instead of (inch), since, on account of the injurious ac tion of the punch on the metal, the metal di rectly around the hole is not considered of value in withstanding stress, and so a portion inch larger than the diameter of the given rivet is taken out.

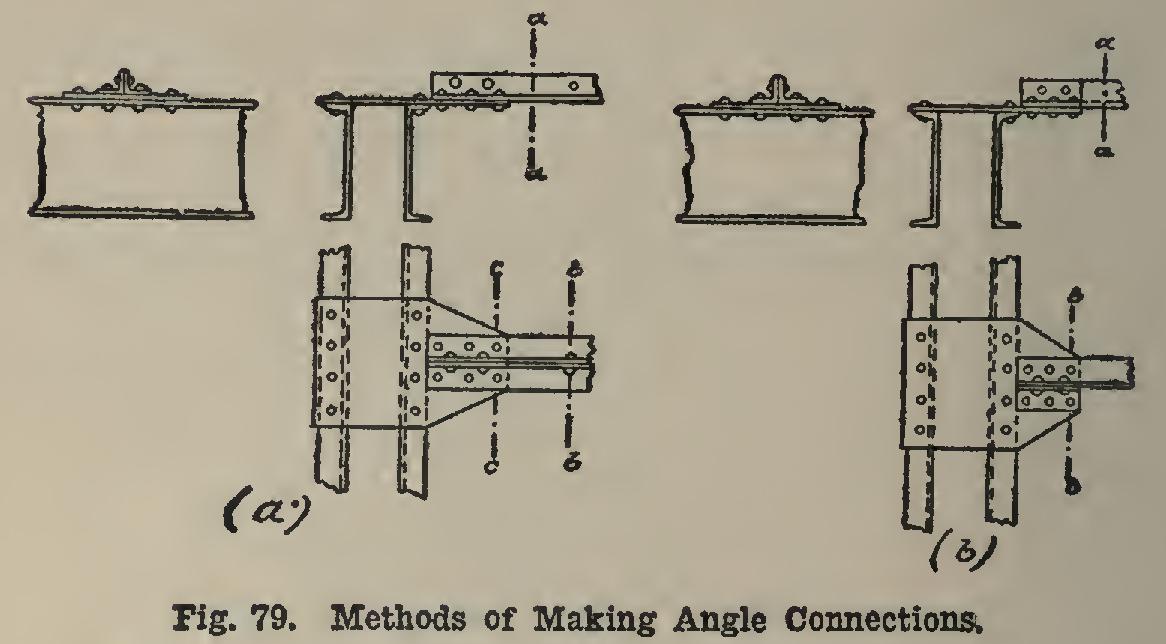

The angle chosen is the one that will be used. Other angles may be chosen and investigated; but it will be found that they will not give areas as near to the required, and at the same time greater. A clip angle of the same size will be used to help connect it at the ends.

(4) If the total stress is 240,000 pounds, the allowable unit-stress 16,000 pounds per square inch, and the rivets design a section con sisting of plates and angles. The pin at the end is 6 inches in diameter.

Required net area=240,000-:-.16,000.15.00 square inches. A common proportion is to make the plates somewhere near one-half this value.

Two 12 by plates give a gross area of (C 250) 4.50X2=9.50 square inches.

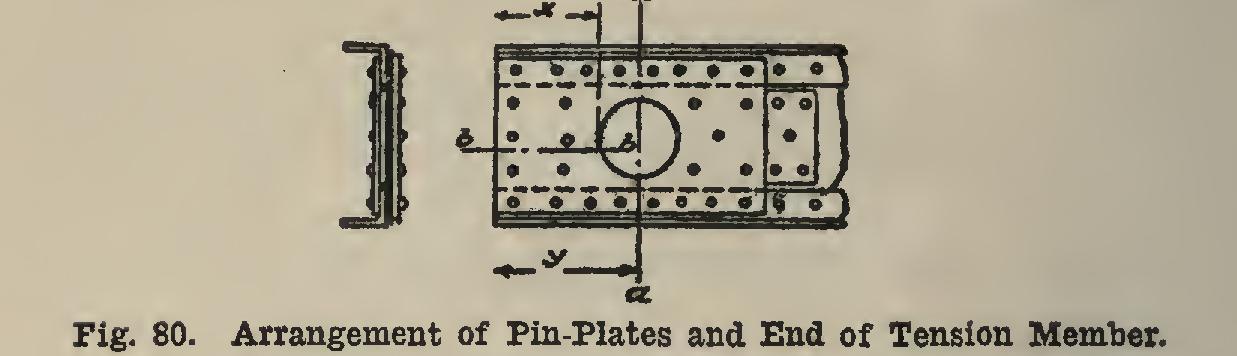

A sketch of the section is shown in Fig. 81. The pin-plate will probably require two rivets to go through the web on each side, making 8 in all to be taken out of the section. The net area of the plate is : 9.5—(8 X 3 X 1)=6.5 square inches. This leaves 15.006.5=8.50 square inches to be divided among 4 angles; and accordingly each angle must be 8.50÷4=2.13 square inches in net section.

By consulting (C 113), a by 3 by angle appears to be about correct. It will be tried.

Gross area, 4 angles=4x2.65=10.60 square inches Out for rivets, 1.76 square inches Total net area=15.34 square inches; or, 8.84÷4=-2.21 square inches each, which is as near as can be obtained. They will be used. The total net area is: Plates 6.50 square inchesAngles 8.84 square inches Total 15.34 square inches At the section through the pinhole, the pin takes out 6X% X2=4.5 square inches; and so the actual section there is only 15.34-4.50= 10.84 square inches, when it should be 15.00X (see page 254) = 18.75 square inches. This shows that plates must be added to make up the difference of 18.75-10.84=7.91 square inches.

As has been said, the pin is as a huge rivet. The bearing value follows the same rule as the rivet (see page 134). If the allowable unit stress were 15,000 pounds per square inch, the bearing value of the pin in the web would be 15,000 X6X%=33,750. Since there are two sides or webs, the value of both would be 2 x33,750=67,500 pounds. This shows that there is a difference of 240,000-67,500=172,500 pounds to be taken up by pin-plates. For one side of the member there would be 172,500-i-2 =86,250 pounds. This requires 86,250-÷15,000 =5.75 square inches bearing on the pin. Since the pin is 6 inches in diameter, the bearing area must be 5.75÷6=0.96 inch thick. This is prac tically 1 inch. This will be made up of two 11-inch by plates placed as shown in Fig. 81.