Classes of Tension Members 50

bar, width, bars, head, fig and diameter

CLASSES OF TENSION MEMBERS 50. Tension members may be divided into two classes—simple members and built-up mem bers. The first class may be still further di vided into eye-bars and single shapes.

Eye-bars are bars with circular ends, in which are holes whereby they are connected to other members by short circular bars called pins. The general form of the head, and also the thinnest bar for any particular width, to gether with the largest pin to be used with a bar of a given width, are to be found in (C 212).

In order to make the head so that when the eye-bar breaks, it will break in the bar part and not in the head, it has been found necessary to make the sum of the distances a greater than the distance w, the width of the bar.

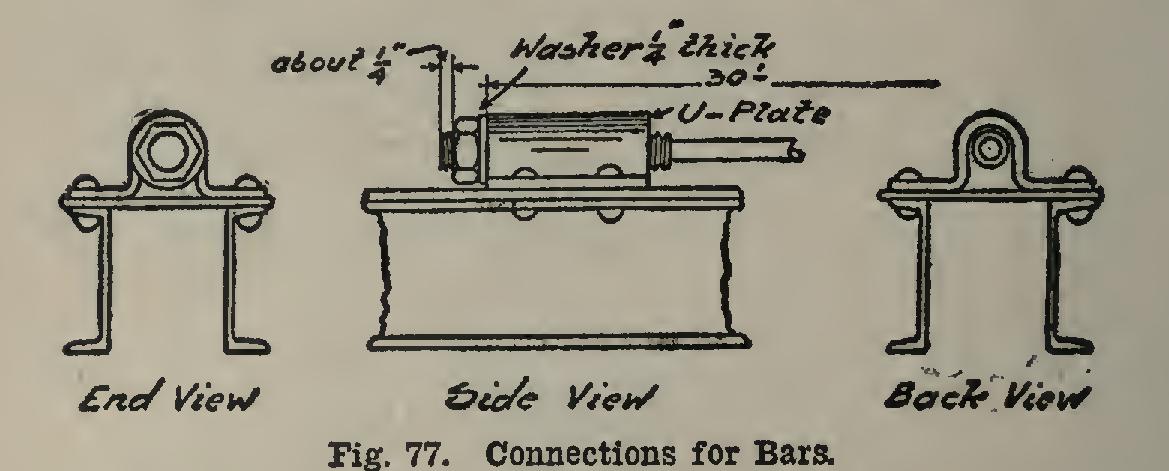

Several different proportions have been used in the past, but common practice now appears to have That is, the area of the bar through the pin is greater than that through the body of the bar. If P is the diameter of any pin, then H, the diameter of the head for a width w of bar, is: H=P+li w, and the result is taken to the nearest half-inch. See Fig. 75.

As an example, let the width of a bar be 8 inches, and the pin be inches. The diameter of the head is: H=6i-1ix8=17.14, say 17 inches.

The pinhole should not be less than two thirds the width of the bar, and the thickness of the bar should not be less than one-seventh the width of the bar. Bars which do not conform to the above requirements are liable to be deficient in strength. The holes in the bar are usually made from to larger in diameter than the pin which is to go through them.

Eye-bars are usually in one piece, being the straight bar with the two heads. These heads may be made of different sizes. In some cases it is necessary to tighten up the eye-bars after they are in position; and then they are made in two pieces with screw ends (C 212), and these ends are connected by either a sleeve-nut or a turnbuckle (C 211). The former is preferable in light work, since, in the latter, ill-disposed persons—especially in the case of bridges—can loosen them up by means of a stick.

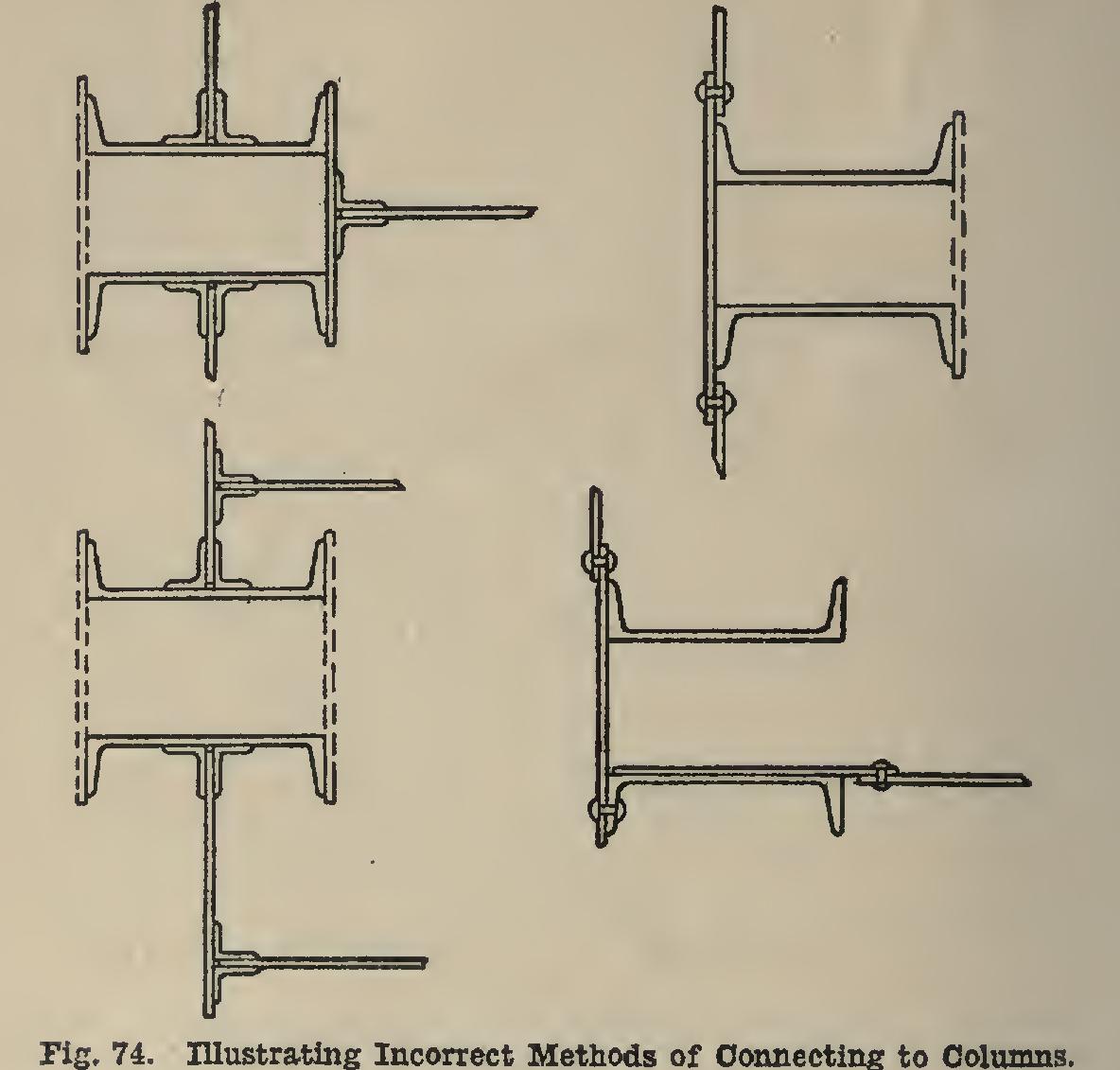

In case the stress is not great, round or square bars may be used. These usually have screw-threads cut on their ends, after first being upset at the ends to such a degree that after the screw-threads are cut the diameter x of the bar at the bottom of the threads will be slightly greater than the diameter of the bar d (see Fig. 76). This upsetting is done by first heating the end of the bar, which is longer than it is re quired to be when finished, and then placing it in an upsetting machine, which forces the end in the form shown. In (C 205-206) is informa tion regarding the upsetting of bars. The reader should carefully read the notes at the bottom of (C 206).

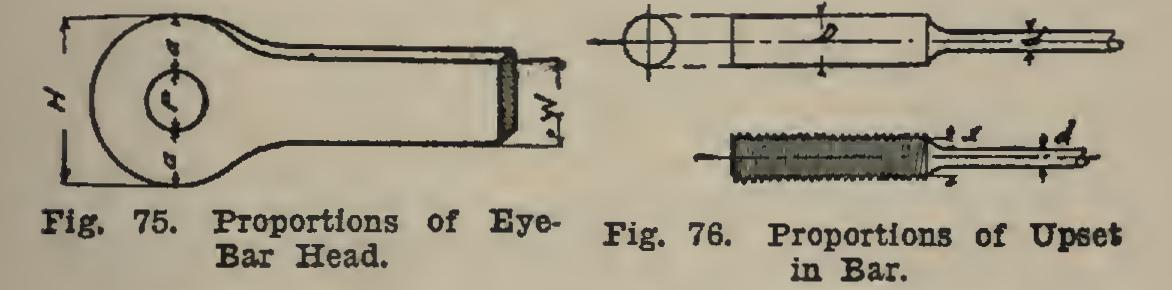

The connection of such bars to other mem bers may be made by means of devises (C 210), or by some form of U-plate as shown in Fig. 77. Sometimes a bolt-head is forged on one end of the bar, and a nut is used on the other end.

The weight of the bar itself may be computed by help of the tables (C 261-266) ; and the weight of the head and nuts, from the table at the bot tom (C 202). According to (C 206), last line on the page, it requires 6 inches additional on the bar, to form an upset for a screw. The sizes of nuts are also given on (C 203-204). Of course the total length of the bar for which the weight is to be computed, must—in addition to the length required for distance from connection to connection, as in Fig. 77, where this is 30 feet— have the length required for the upset and the thickness of the nut, and then a small amount (say inch) additional to one or both ends, de pending on whether there is a nut at one or both ends.

Another form of simple tension member is the flat plate, which is connected to other mem bers at its ends by being riveted. It is coming more and more into favor; but, if used, the con nection should be made as shown in Fig. 78, a, and not as in Fig. 78, b.