Cement Floors and Steps

concrete, mould, desired, treads, core, ground and length

Steps for Residences.

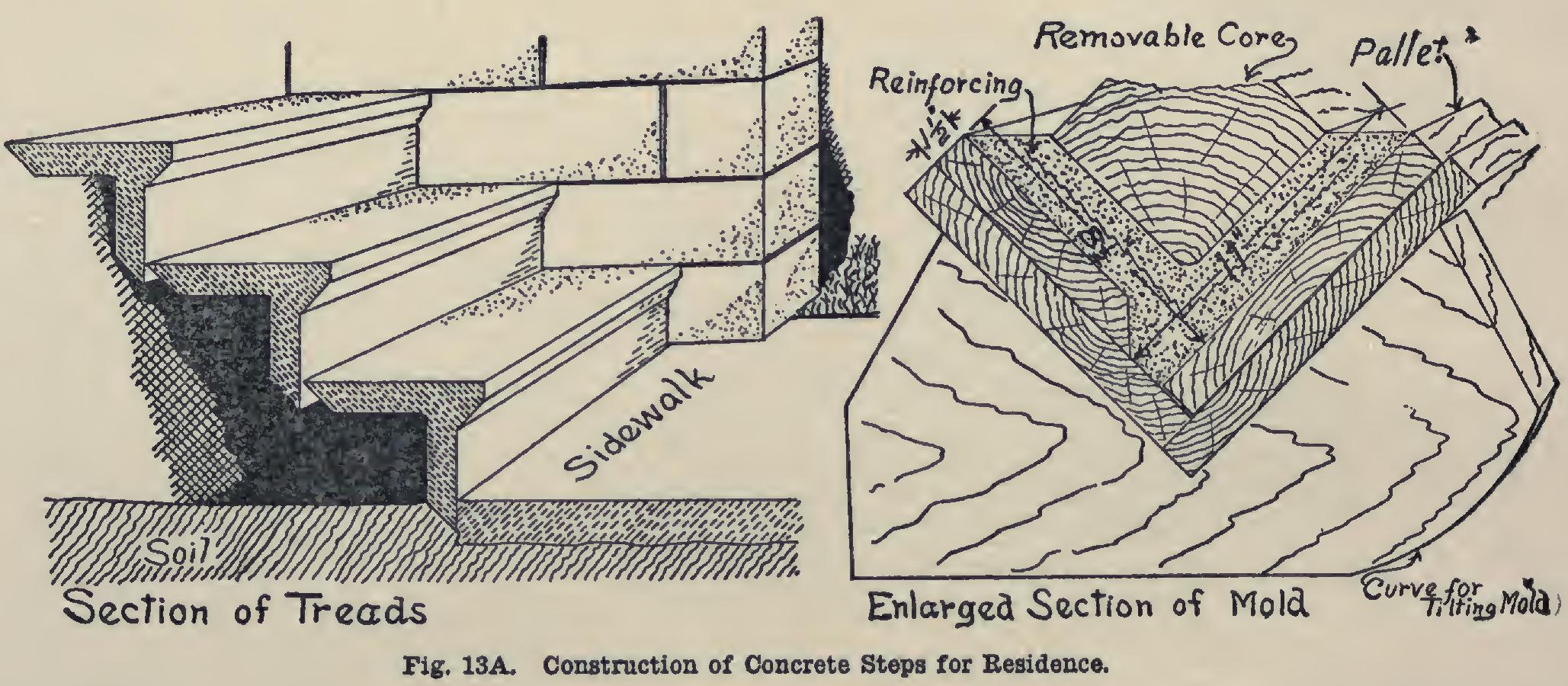

The growing demand for concrete steps for residence entrances has led to the construction of the type of step shown in Fig. 13A. These steps or treads are made at the hollow block plant and kept in stock. The mould, a cross-section of which is shown, is in expensive and allows the use of rich mix for facing, and wire cloth or expanded metal for re inforcing, being practically a face-down mould with a round corner on the skids for tilting up before removing the pallet.

The tread and riser are adapted to any height of riser, as a study of the section steps shows. Should a narrow tread be desired, it is easy to trim down the pointed edge projection against the riser above.

The cost of these treads is less than solid ones, there being a saving of half the concrete, a saving of labor in applying the richer facing, and only two-fifths the weight to handle.

Only one mould is necessary, but the remov able core should consist of several short blocks, so that any length can be met.

The pallets should be of sufficient length for the longest steps required, and the ends of the mould sliding over the pallet permits short lengths being made on long pallets.

When return ends are desired, a special end board is necessary, which, with an extension on the end of core, admits making a full end of step, thus making the supporting wall at end of steps unnecessary.

When making cement walks, it is surprising to learn how much time these treads save over the old method of using forms; besides, for ad justing a number of steps to meet a given height, these treads have no rival.

Only two-inch surfaced lumber should be used for making the mould, and the skids should not be more than three feet apart. The remov able core need not be solid as shown; but this is preferable, for, by tamping this core after the mould is filled, the concrete becomes very compact.

Round rods can be used for reinforcing, but wire cloth or expanded metal lathing is prefer able, being more binding and nearly always cheaper.

The supports for these steps are the same as for stone—namely, supporting walls under each end, also a center wall under center for lengths of six feet and over.

Concrete Steps in Damp Places. Concrete may be advantageously used in the construction of steps, particularly in damp places, such as areaways and cellars of houses; and in the open, where the ground is terraced, concrete steps and walks can be made exceedingly attractive.

Where the ground is firm, it may be cut away as nearly as possible in the form of steps, with each step left two or three inches below its finished level. The steps are formed, beginning at the top, by depositing the concrete behind vertical boards so placed as to give the necessary thick ness to the risers and projecting high enough to serve as a guide in leveling off the tread. Such steps may be reinforced where greater strength is desired, or where there is danger of cracking due to settlement of the ground.

Where the nature of the ground will not ad mit of its being cut away in the forms of steps, the risers are moulded between two vertical forms. The front one may be a smooth board; but the other should be a piece of thin sheet metal, which is more easily removed after the earth has been tamped in behind it. A simple method of reinforcing steps is to place a half inch steel rod in each corner, and thread these with quarter-inch rods bent to the shape of the steps, as desired, the latter being placed about 2 feet apart. For this class of work, a rich Portland cement concrete is recommended, with the use of stone or gravel under one-half inch in size. Steps may be given a half-inch wearing surface of cement mortar mixed in the proportion of 1 part cement to 2 parts sand. This system, as well as many others, is well adapted for stairways in houses.