Cement Floors and Steps

walls, top, concrete, sand, edge, mixture, cast and inches

The next operation is to spread on the wire a layer of concrete about three inches thick con sisting of one part Portland cement, three parts clean, coarse sand, and six parts gravel or broken stone. Sufficient water should be used to make a mixture that will work through the wire cloth and completely surround it. Tamp well, and permit the concrete to stand for twenty-four hours. Starting at the top, place the boards be tween the planks to form the risers of the steps. The inner top edge of each board should. be grooved in a circular form to form the bottom of the nosing of the tread. Each board should be fastened securely to the planks. Just before the next mixture of concrete is applied, the base of the concrete laid before should be wetted. The forms should be filled with a mixture con sisting of cement mortar—one part cement, and two parts of clean, sharp sand. Trowel the top, and round at the edge to conform with the groove in the riser board.

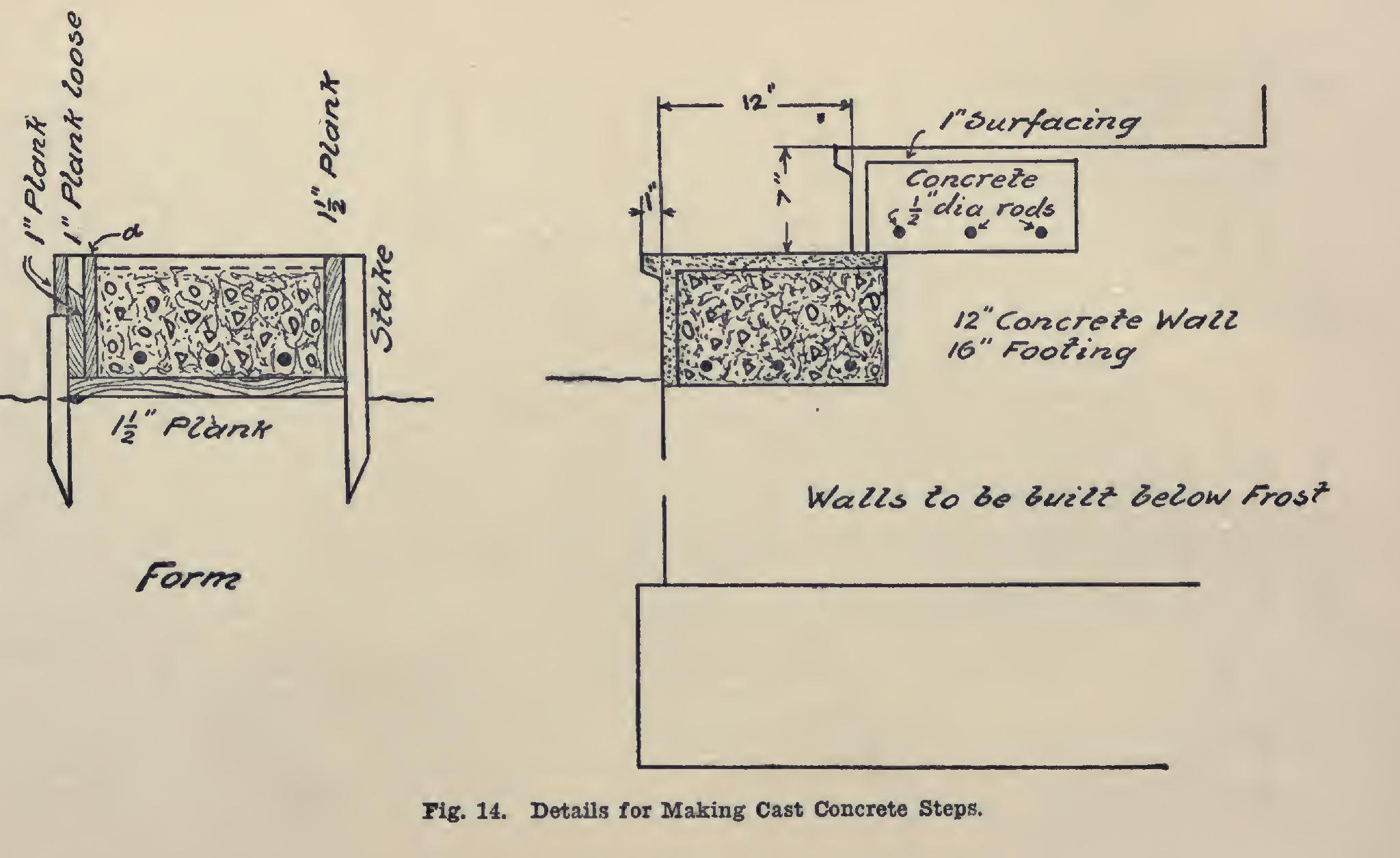

Porch Steps. Build two 8-inch walls to a depth below the frost line, and make sure that the upper surface conforms to the desired pitch of the steps, but three inches below the point where the inner edge of the tread meets the rise. Between the walls, build a platform out of 2 by 4 stuff, well braced and conforming to the slope of the walls. Over this, and over the top edge of the walls, put a three-inch layer of concrete re inforced every foot by iron bars run ning from top to bottom. Build up the form on the outside of the walls, and proceed in the same manner as for terrace steps. Should the steps be more than 6 feet wide, a wall similar to the two side walls should be built in the center, to assure sufficient strength. The forms should not be removed from under the steps for 28 days. If more than three or four steps are required, the iron rods must be of larger size and nearer together.

Platform Steps.

The best proportion to use is one part cement, and four to five parts sand. Blocks thus made will resist wear well. For the wearing surface, one part cement and two parts sand will be better; but the wearing coat need be only half an inch thick, provided both coats are mixed and used at the same time, al lowing the cement in both mixtures to unite. Wood moulds made of surfaced lumber coated with liquid shellac, oil, or paraffin, will not ad here to the cement. The proportion of cement and sand is necessary to secure uniform and sound work as well as color. Plaster for the outside work should be made of cement, as lime disintegrates; besides, fresh lime requires much more water than cement, hence they never should be mixed together. Cement always contains sufficient lime that has been properly treated, so that no more lime is required unless a cheaper product is wanted.

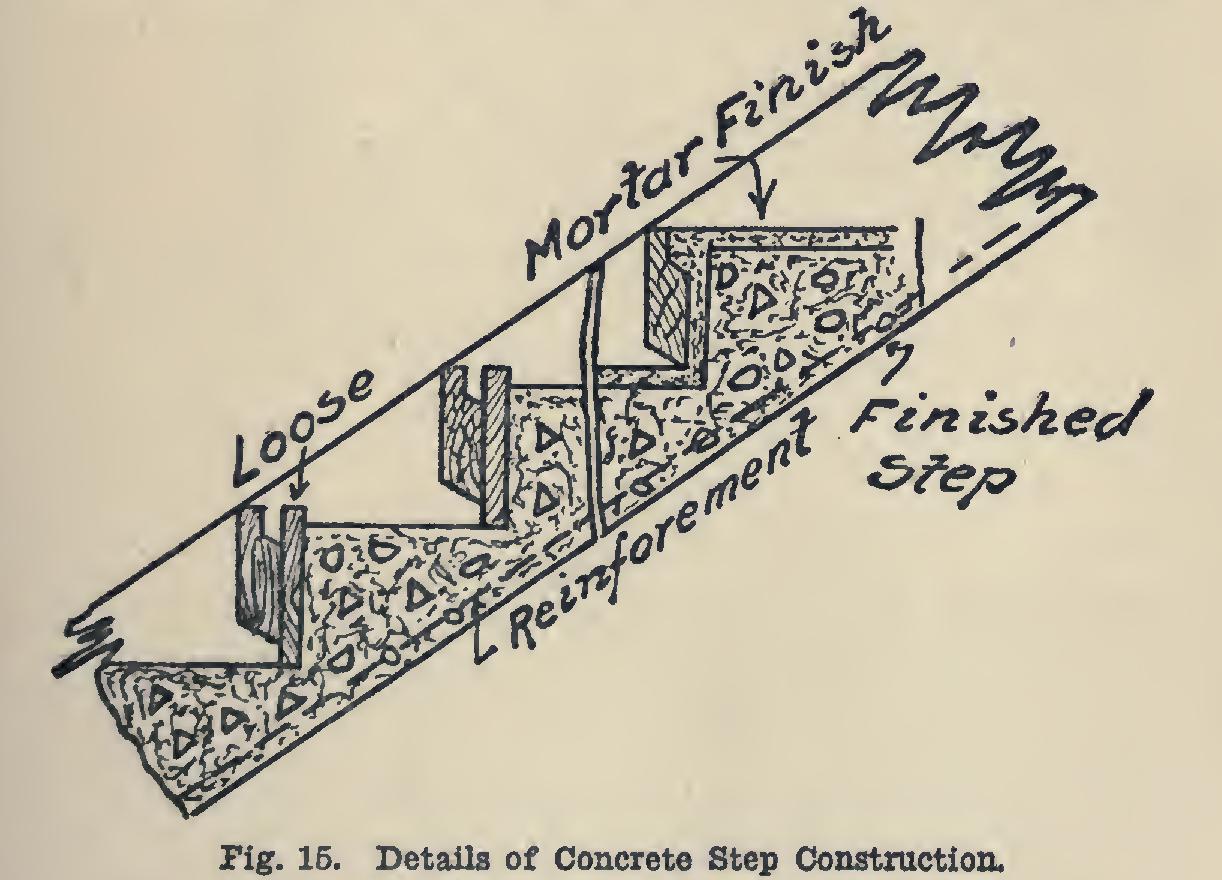

Cast Steps. Steps made in this manner should be given plenty of time to season before they are used or put in position. The making of cast steps is similar in a general way to the making of cement blocks, in that a form is used. This form should be of plank, and the inner sur face should be smoothly dressed. One side of the top edge should be grooved to provide for the projection of the tread over the riser. The concrete should consist of one part cement, three parts sand, and six parts broken stone. Fill the box or form with the mixture to within one inch of the top, leaving that space for the finishing coat, which should be put on imme diately. Dress the top with 1 part cement and parts sand, rounding the edge to conform with the groove of the projection. After the cement is set and hardened, the form may be removed, and used for another step.

Side Walls for Steps. In building the side walls for steps of this character, the foundation should be twelve inches wide, and should start below the frost line. On this foundation, and at equal distances from each edge, erect eight inch walls, stepped off to conform to the width and depth of the cast steps. Place the cast steps on the walls thus made, covering the joints and finishing neatly with cement mortar. If the steps are more than three feet long, they should be reinforced with half-inch iron rods placed in the center of the steps, about three inches apart.

Making the Slabs. The formula for concrete used in this work is 1 part Portland cement mixed dry, to parts of crushed slag and granite equally. The granite and slag should be of a size that will pass through a sieve. The method of mixing is mechanical. The parts are placed in a horizontal cylinder and thorough ly mixed. The mould is placed on a shaking ma chine after being previously oiled; and after the machine, which gives to the mould a rapid ver tical motion, is started, the concrete is laid on the mould in small quantities, and it is smoothed off with a trowel. The moulds are removed, and permitted to stand for three days. Then the slabs are taken out, and stand five days more. A silicate bath is then used for immersing the slabs, and they are allowed to remain in this a week. After this process, the slabs are taken out, and are dried in the open air. It is not thought best to use them until after three months.