Cement Floors and Steps

mastic, stairs, surface, floor, sand, material and coat

CEMENT FLOORS AND STEPS Sarco Mastic. For manufacturing establish ments where it is desired to have absolutely waterproof floors, "sarco mastic" is used in con nection with "sarco flux" on cement floors. The mastic is broken up into small pieces, and placed in a suitable kettle, together with a certain per centage of the flux, and heated to about 450° F. After the materials have been cooked at the above temperature for from two to four hours— depending upon the size of the batch and the construction of the mastic boiler—a certain per centage of grit should be added. This grit is procured in the vicinity of the work, and should be entirely free from loam and dirt, not larger than No. 4 torpedo or fine limestone or granite screenings. The grit is thoroughly stirred into the mass with suitable stirring rods, and sub jected to the same degree of heat that was used to break down the mastic, for a period of one to two hours, depending, as before, on the size of the batch and the construction of the mastic boiler.

After the material has been thoroughly cooked and mixed, it is shoveled from the boil ers into oak buckets or into wheelbarrows, care being taken (in case of carrying any distance from the boiler) to keep the material covered to hold the heat.

When applying to the surface to be covered, the material is spread out as much as possible by the carrier, and then distributed evenly over the floor to the proper thickness by the spreader, and rubbed smooth.

Veranda Floors.

Concrete floors for veran das, porches, and even balconies are much to be desired. While they cost a little more than wood, they are imperishable. Such floors may be built on the ground the same as walks, or on rough wooden supports. One part of Port land cement, three parts of sharp sand, and three to five parts of gravel, mixed with sufficient water to become plastic, and tamped in position to a thickness of 3 inches, is the rule. The wearing coat is a half-inch thick, and made of one part Portland cement and two parts sand. The top coat should be smoothed with a plas terer's trowel, and allowed to stand for six to eight days, being kept damp.

Jointless Floors.

The use of jointless floor ing, made from pulverized wood fiber and other material, and laid in a plastic state on a cement foundation, was begun in Germany about ten years ago. This flooring has proved so successful that several other mills manufacturing the same product have been started, and are now running prosperously. The problem has been to make a continuous flooring, which will fit closely at its junctions with the upright walls, and be not only fireproof, but impervious to liquids, dust, and vermin of all kinds. The ex perts at work on the problem hope to succeed in producing a flooring, too, that will be a poor conductor of heat and sound, easily cleaned, neat, and attractive.

Cellar Floors.

Cellar floors may be laid without foundations, except in places where there is danger of frost getting into the ground below the floor. The dirt should be evened off and tamped hard, and the concrete, one part Portland cement, two and one-half parts clean, coarse sand, and five parts broken stone, spread over the surface in one continuous slab 3 inches to 4 inches thick, lightly tamped to bring the water to the surface, and screeded with a straight-edge resting upon scantlings placed about 12 feet apart. The scantlings are then withdrawn, and their places filled with concrete. No finishing coat is needed unless the floor is to have excessive wear. The surface of the con crete, however, should be troweled as soon as it has begun to stiffen. Joints about 12 feet apart should be made if the surface is more than 50 feet long, or if it is to be subjected to extreme temperatures.

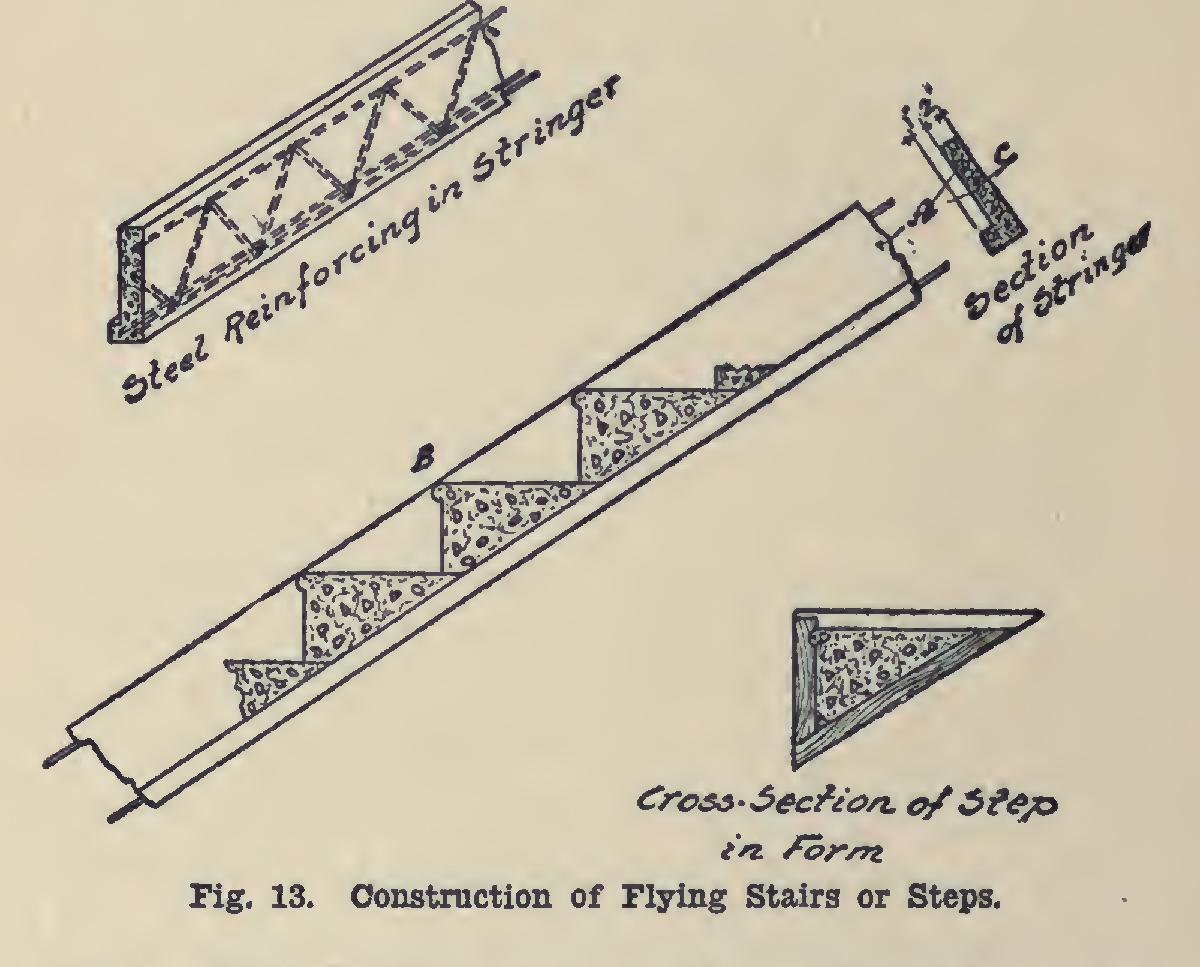

Flying Stairs or Steps. In constructing "flying" steps or stairs, first make the steps as in Fig. 13 and allow them to season. The strin gers are cast in place, being constructed as in clined beams of sufficient length, and with a pro jection along the lower inside to support the steps. Place two bars about inches in from bottom, and one of the same diameter at the top, the three being connected. The rein forcing, however, depends upon the depth and pitch of the stairs, also on the weight they are to carry. Stairs are put in place with the lower edge resting against the upper corner of the stair below, a small notch being left in each stair for this purpose. A finishing coat of one part Portland cement and one part clean, coarse sand is given to the stairs after all are in place and have been picked with a stone ax and wet. This binds the whole flight together.