Color Variations

concrete, wall, walls, mould, time, system, size and built

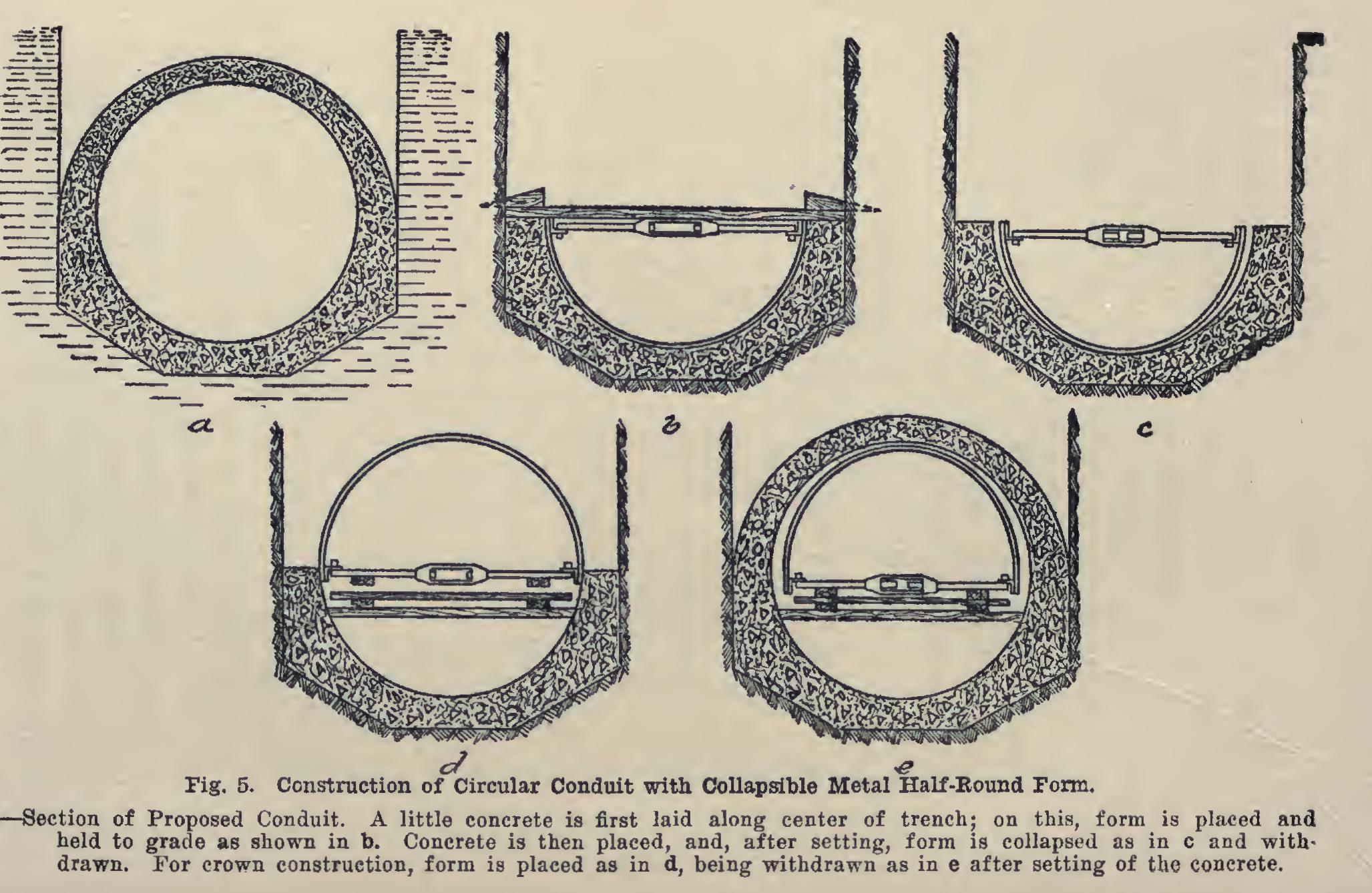

Where one culvert is of insufficient size to carry the water, and it is desired to keep the depth of the same down to a minimum, two or three outlets may be made for the water.

The Overturf Mould.

Another mould of the collapsible type is known as the "Overturf." The only lumber needed in culvert construction in connection with this mould is that in the coping moulds. The method of using the Over turf mould is very simple. After the ditch has been dug, the coping forms placed in position, and a bed of concrete laid up to the point that the culvert is to occupy, the mould is laid on this bed of concrete, and set at each end into the forms for it on the coping moulds. The mould is bolted up with bolts extending straight from the top, and all is ready for laying the concrete. After the concrete has set sufficiently, the bolts extending up through it are loosened and screwed up and out, thus releasing the mould, which is self-collapsing, for removal.

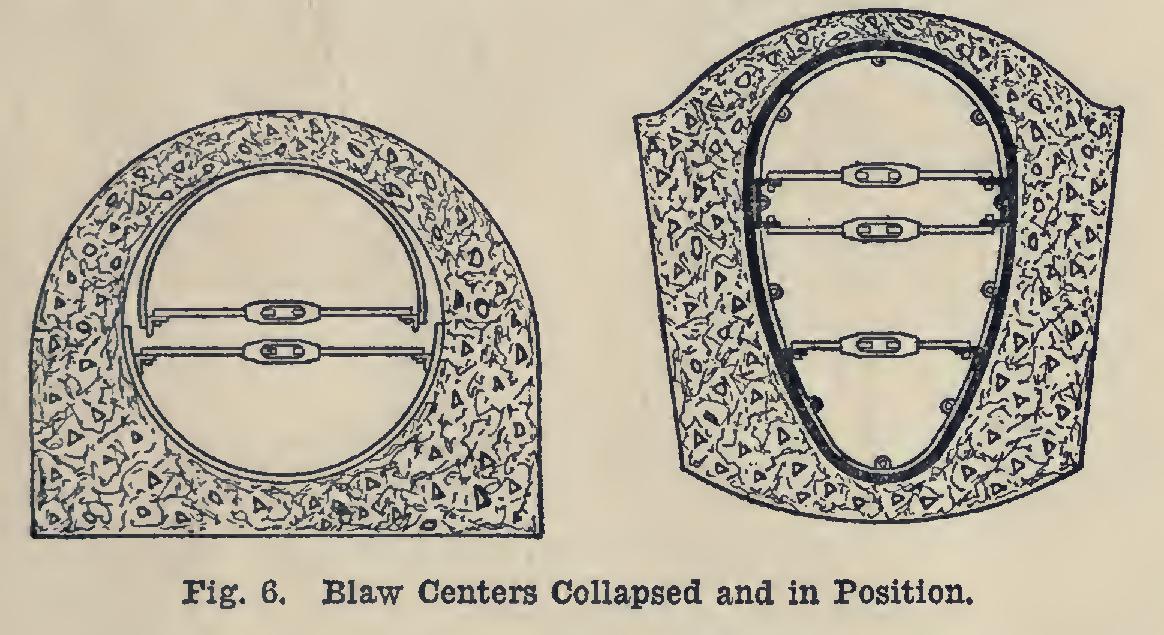

Blaw Centering.

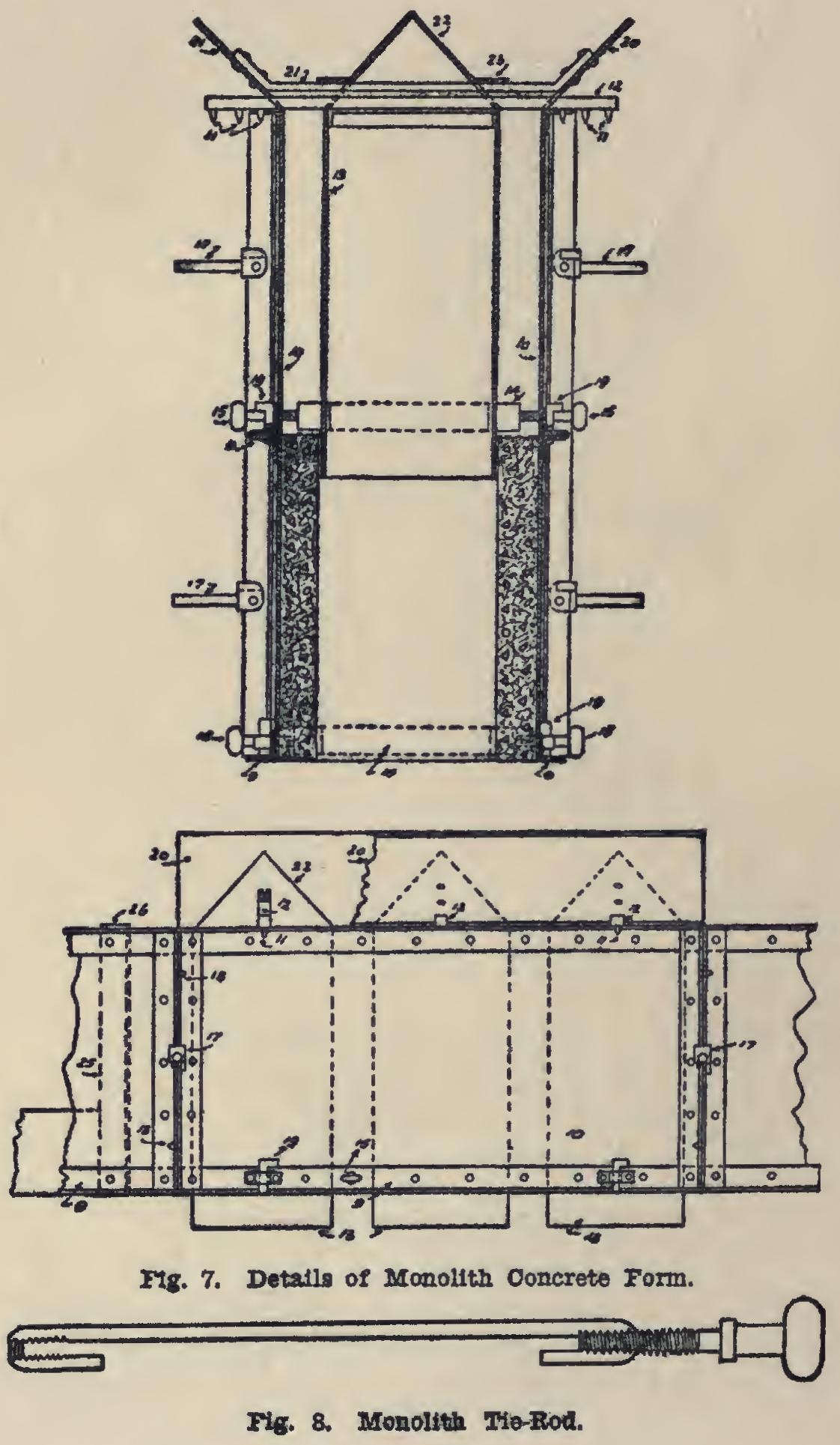

The "Blaw" collapsible steel centering is used extensively in the con struction of sewers, conduits, and other under ground work. The centering is in the nature of a steel cylindrical form consisting of plates that are held in position by rods on the interior. When it is desired to remove the forms, these rods are unscrewed, and the form is released. Systems of Forms for Building Construction Monolith System. A considerable item in the cost of building concrete walls, as already noted, is the labor and lumber required for the forms. The "Monolith" system of concrete con struction is a metal substitute for wooden forms, with separate cores to make a wall hollow.

These can be set together by even unskilled labor to any length or height or width, according to the size and number of forms, and it is claimed that they can be put up in two-thirds of the time required for the erection of wooden forms.

These forms are made of No. 16 gauge gal vanized sheet iron, riveted to 1 by 1-inch angle iron. For ordinary use the 24 by 24-inch size has been found most convenient to handle. The cores are made of wood, and can be used for any thickness of wall. They are made in several sizes—the cylindrical, 6 in. diameter, for 10-in. and heavier walls; and the. 3 by 6-in. for 6-in. to 10-in. walls. They are made in 24-inch lengths, but can be made almost any size. These cores have a cross-bar on top, which has pins at the ends serving to connect the side plates together, and giving the different thicknesses of wall. Tie

rods are required, one for every two feet, but, if desired, may be used only in bottom course, and wire used for the balance, They are furnished for any width of wall. The tie-rods remain in the wall and act as a reinforcement.

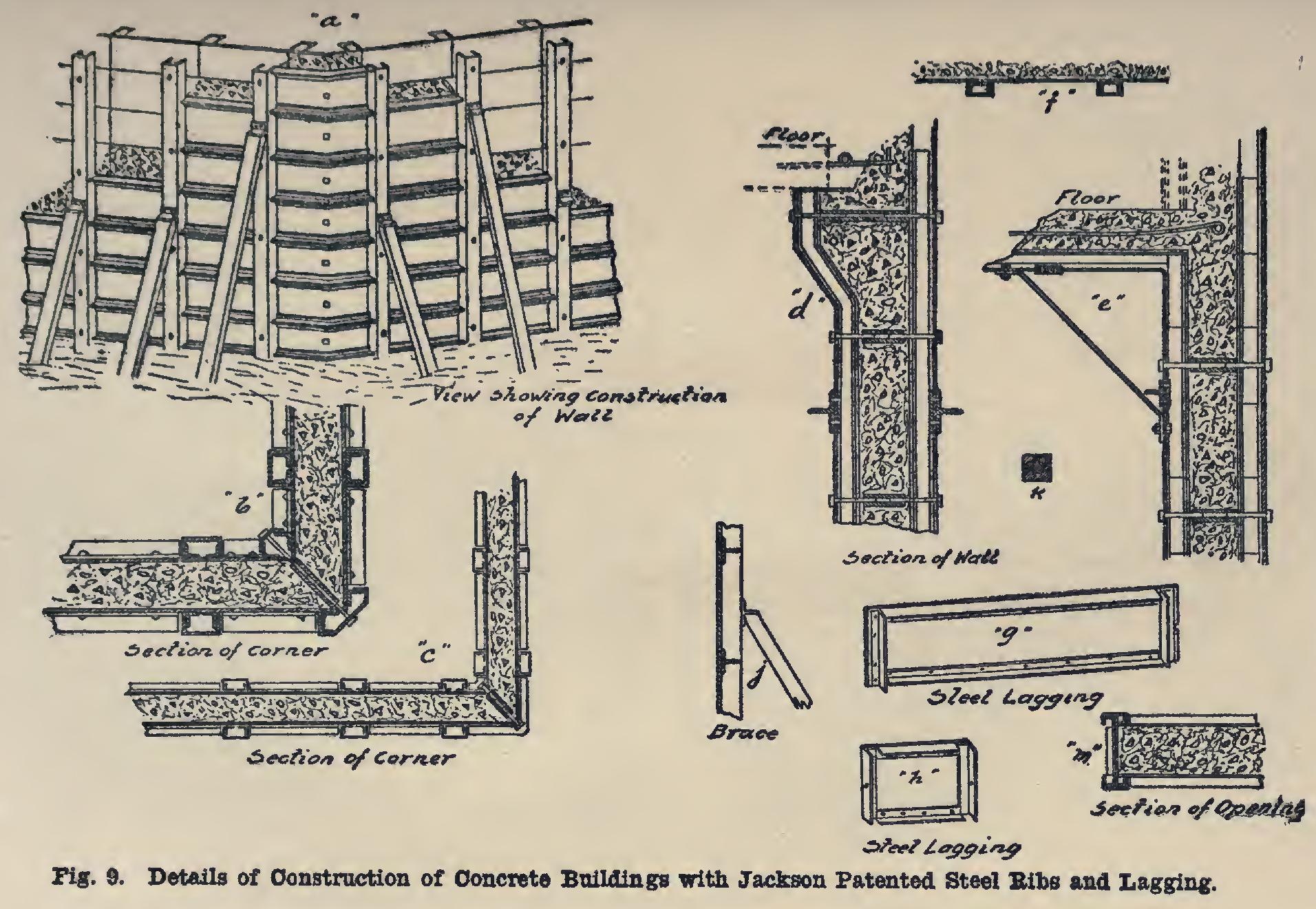

The Jackson System.

In order to reduce the time and cost of material for concrete structures, there has been developed and patented a system of concrete forms, known as the "Jackson" sys tem, for concrete buildings, as well as for bridge piers, retaining walls, dams, foundations, arches, and reinforced concrete work of every descrip tion. The use of this appliance, it is claimed, cuts the time one-third and the cost of forms seventy per cent, and absolute accuracy of lines and surface is assured by the perfect fitting of the steel plates.

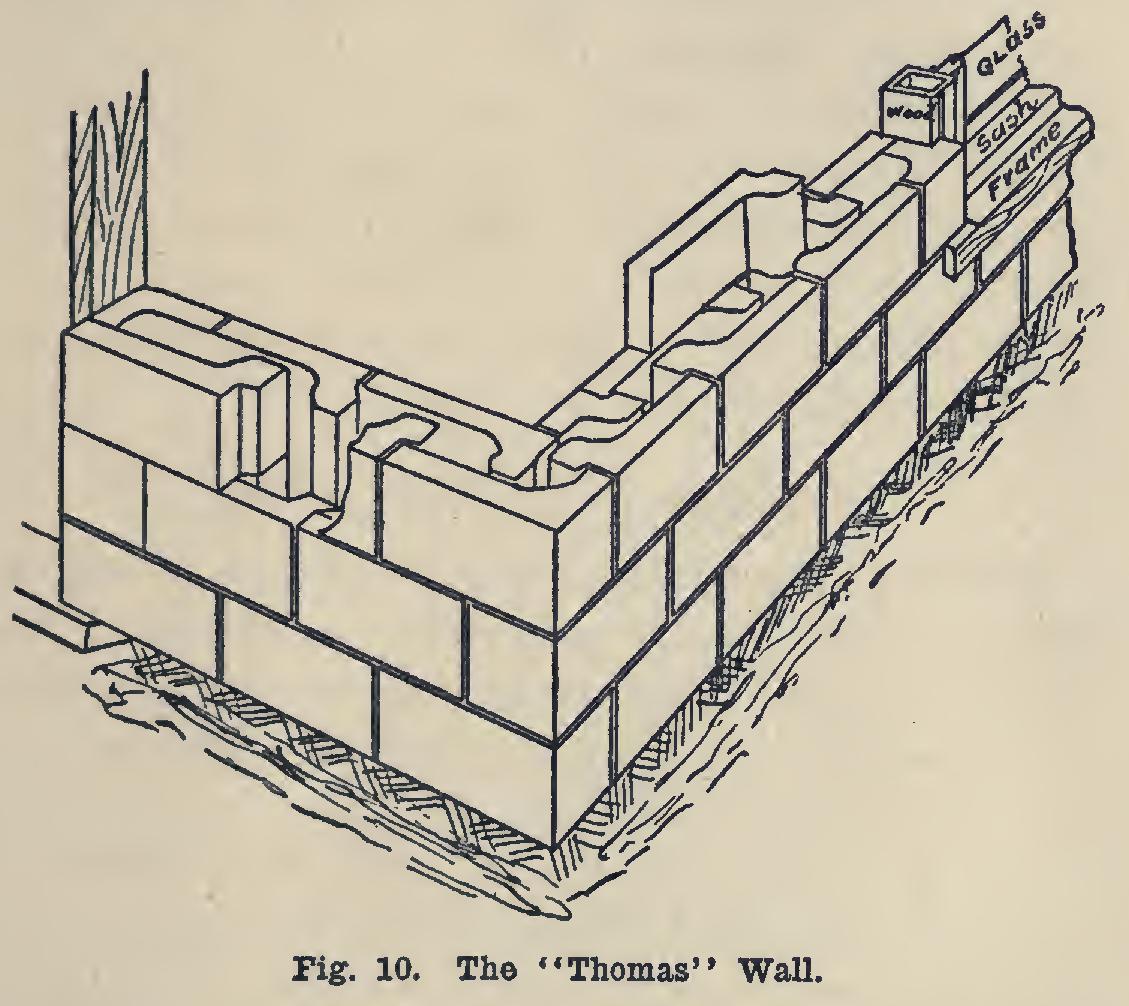

General Remarks. Every wall should have a footing—that is, a base which is wider than the wall it carries. A foundation must extend below the frost line, and must also extend through soft or yielding soil.

Walls are of two kinds—solid and hollow— and may be either plumb, the same thickness at top as at bottom, or battered, wide at the bottom and sloped toward the summit. They may be built in two ways—first, cast in blocks and put in place the same as brick or stone; second, cast in place in one piece (monolithic). Walls must be true, level, and—unless battered—plumb.

Hollow walls

are usually built with two faces 3 inches to 4 inches thick, and are either tied to gether with galvanized iron strips or have piers of concrete connecting the two faces. These piers are built at the same time as the faces, and the whole is practically one wall, with air chambers at regular intervals. Walls should be allowed to season before any superstructure is built upon them, to prevent their being injured by workmen. In dry, warm weather, this will require from six to eight days. Earth should not be filled in against a concrete wall for three or four weeks, unless the form farthest from the earth is kept in place. Where there is no earth or water pressure against the wall, 24 hours, or until the concrete will withstand the pressure of the thumb, is sufficient length of time to keep forms in place. For this reason it is well to have two or more forms, where movable forms are used. In building forms, they should be as sembled, as far as possible, with bolts, so that they may be used again.