Color Variations

wall, inches, concrete, walls, thick, blocks and building

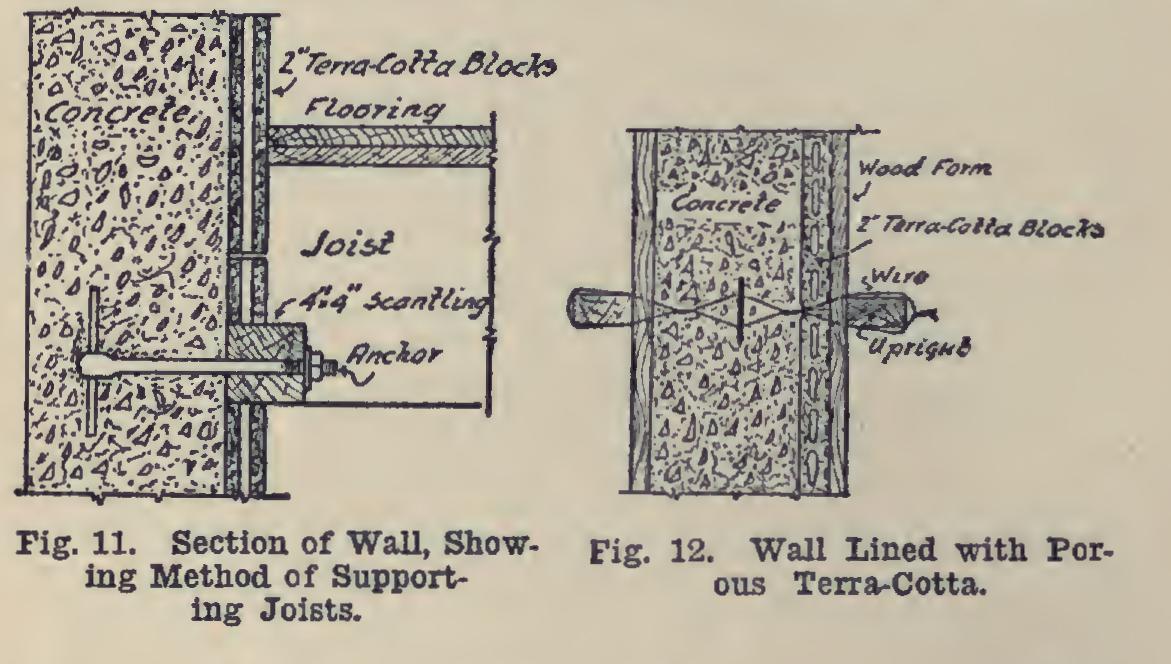

Window- or door-frames should be put in place, and the wall built around them. Cellar walls should be from 10 inches to 12 inches thick for frame superstructure; and 14 inches to 24 inches thick for brick, or about 2 inches wider than the brick wall, for convenience in laying out the brickwork.

Contraction in walls should be provided for by forming joints at intervals to divide the walls into separate sections to prevent cracks, or by reinforcing with sufficient steel to withstand shrinkage. These joints can be provided for in the following manner: The simplest way is to place a temporary dam between the forms, to remain until a section of concrete has set, when it is removed and the next section filled.

Another way of forming a joint is to insert two or more thicknesses of tarred paper between sections of the wall.

House Foundations. As a general rule, the base of a wall of any kind should be at least fifty per cent wider than the wall itself. For instance, a 12-inch wall should have a base of 18 inches, which will ordinarily give sufficient thickness to prevent settling. It should be remembered in building the base of a wall, that the entire weight of the building and all its contents is to rest thereon. The stronger the base, the more lasting the building. Another important factor is the necessity of starting a wall below the frost line and below soft or yielding soil.

Excavating.

In building the foundation for a house, the first step is the excavation to the desired depth of the cellar or basement. Around the edge, if the house is to be of moderate size, dig a trench eighteen inches wide and six inches deep, and here build forms for a wall of the thick ness desired. The dimensions of the trench and footing will, of course, depend upon the thick ness of the wall and the weight of the super structure.

Proportions.

The concrete for the wall should be one part cement, two and one-half parts sand, and five parts gravel or broken stone. It should be rammed carefully, and the concrete at the bottom should be allowed to flow out and fill the trench to the desired height. The con crete should be allowed to set hard before re moving the forms. In clay soil the outside of thefoundation wall should have a good coat of cement mortar. If earth is filled in against the back of the wall, the face forms should be left for three or four weeks, but the superstructure may be begun in about a week, contingent of course upon weather conditions.

Partition Walls.

Partition walls are con structed in the same manner as outside walls, but need not be more than 8 inches thick. If re inforced with 1/4-inch rods spaced 18 inches apart horizontally and vertically, 4 or 6 inches will be thick enough for a wall above ground. In wet ground, to prevent moisture from soaking through, it is well to give the back of the wall a coat of one part Portland cement and one part sand, one-quarter inch thick, applied with trowel and wooden float, after picking the wall well with a stone axe and wetting thoroughly. There is little danger, however, of moisture passing through a well-laid wall, if a blind drain of coarse gravel is laid just back of the foundation, to carry off the water and prevent its rising back of the wall. In gravel or sand, the blind drain is unnecessary.

Concrete Blocks for Foundation Walls.

For basements less than twelve feet in height, a wall eight inches thick is sufficient for supporting a two-story frame building. The size of the blocks is a matter of taste, but no block should be longer than four times its height, or shorter than one and one-half times its height. The best builders favor blocks that are two times as long as they are high. Crushed stone that passes a three quarter-inch screen is best for strength, although it is rough in appearance. The best proportion of ingredients is cement one part; sand, three parts; and crushed stone, one and one-half parts.