Color Variations

concrete, using, finish, surface, monolithic and boards

COLOR VARIATIONS One of the difficulties encountered in plaster and monolithic wall construction is a variation of color between the various layers of concrete that are deposited, and also the tendency in monolithic walls of the aggregates and stones to show on the surface, separating themselves from the matrix, or cement. This variation of color may be due to variation in the character of the sand or to non-uniformity in proportions or mix ing, or possibly to other causes. An artistic method of overcoming these difficulties is to cut the surfaces by grooves or channelings, giving the surface the effect of stone work. For this purpose the V-shaped form has been found to be best adapted. The V is placed in the form at intervals of eight or ten inches and when filled produces the familiar panel finish.

Proper Finish.

Monolithic construction, to bring the cost of mill work for the forms within reasonable bounds, should be of simple design, involving no elaborate or intricate detail of mouldings or cornice effects. The use of the quarter-round is suggested, and all forms should be beveled so that they will pull away readily from the concrete without breaking off any edges. The proper finish for all exteriors of monolithic buildings is being given much atten tion by architects. It has been found that no matter how carefully the forms are made, when they are removed the wall has a cast appearance that is not desirable. A method frequently adopted to remove the pasty texture of the sur face is to use a sand blast. This gives the surface a rough appearance, but in most cases the edges of the seams have to be dressed by hand.

Rubbing Down.

Another finish has been ob tained by oiling the forms and rubbing down the work after it is finished with carborundum blocks, and using cement paint, which is made with cement and water. The carborundum block cuts away the irregularities on the surface and the paint fills in the crevices, the two producing smoothness. Of course in the case of a very large building this would be a laborious process, but for a residence it is not a difficult or ex pensive operation.

Circular Forms.

In a circular form there are two sides—the inner and the outer. These may be used together, as in building a silo; or, as in a cistern, using the inner form alone; or for a column, using only the outer form. Both sides of the form are made in the same way; but the inner and outer sides cannot be made to the same pattern, as the thickness of the walls comes between the parts, making the radius of each side different.

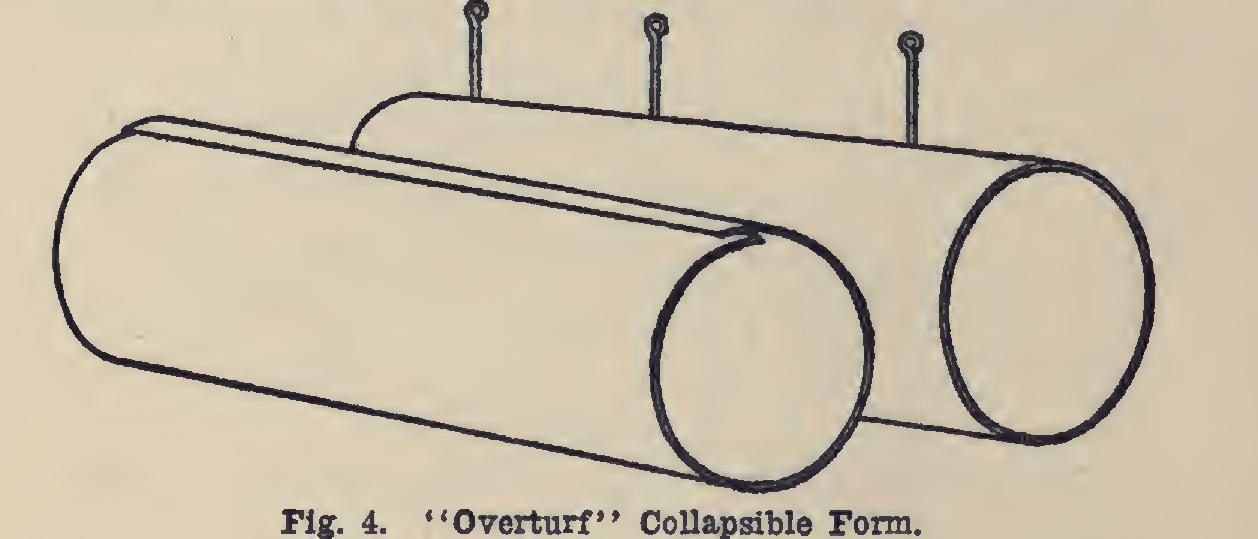

The simplest way to make a circular form is to draw a circle of the size of the form desired, and lay boards around the circumference of the circle as shown in Fig. 2 at a. These boards should be lightly tacked together in place, and, using the same measure, mark a circle upon them. They should then be knocked apart, and sawed out along the lines marked, the pieces being fastened securely together, as shown in diagram. After making two or more forms, place them at equal distances apart, and put on the side boards in the manner shown in the illus tration. These boards are called lagging.

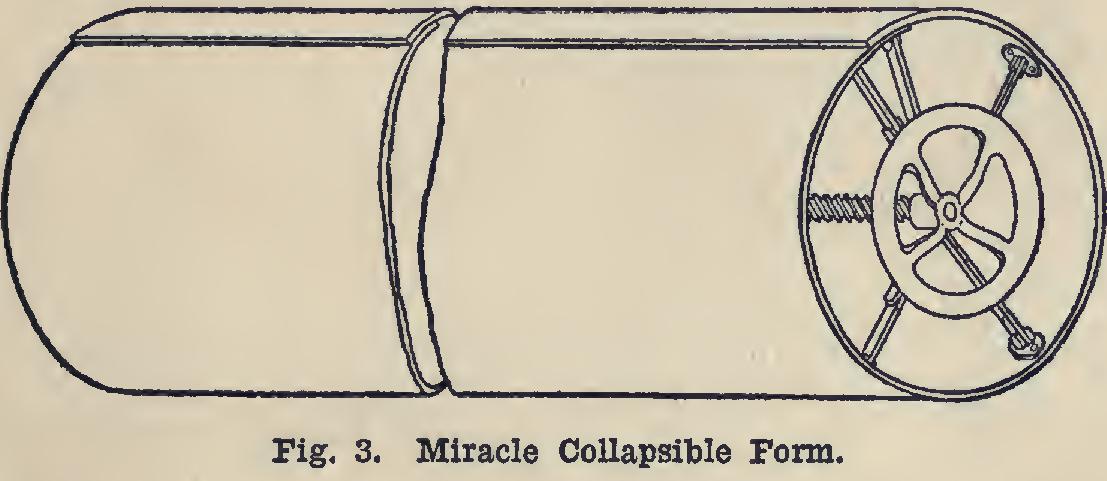

Culvert Forms Miracle Moulds. In the many highway im provements that are being made throughout the country, we find a large demand for concrete culverts. The old-fashioned vitrified clay pipe culvert has been found insufficient for this pur pose, on account of filling with water from time to time, and freezing and breaking during the winter months.

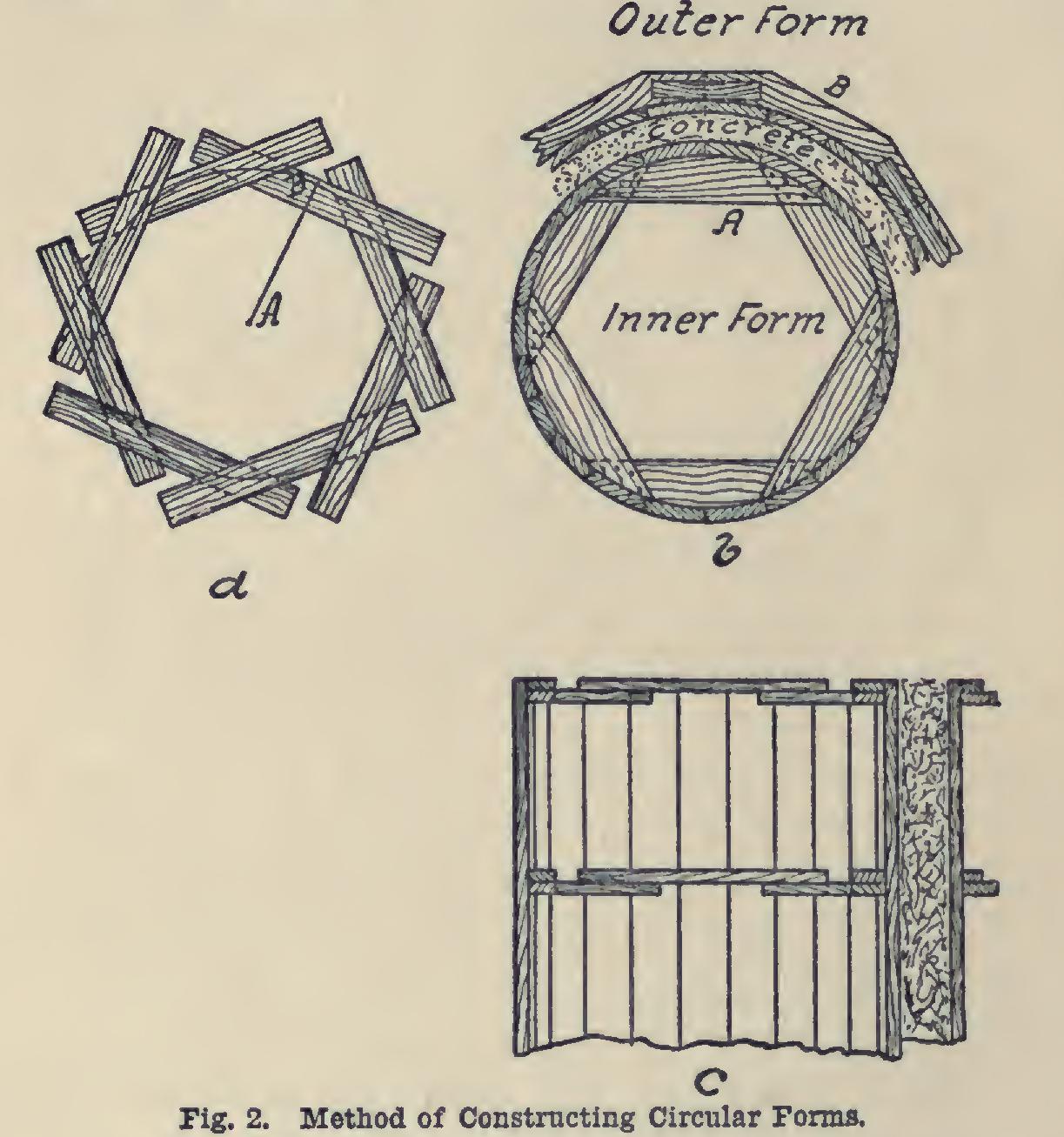

One of the metal forms used in making cul verts is known as the "Miracle." It is of the collapsible type, and permits of the use of as heavy a wall of concrete as may be required, and also of the use of reinforcing metal, if desired. The trench is dug and the concrete bottom put in place; and the forms are then laid in, the con crete being tamped around them and finished to the desired height and thickness. Then the forms are collapsed by turning the wheel at the end of the form, which enables the forms to be withdrawn.