Concrete in Barn and Stable Construction

inches, floor, sand, floors, cement, portland and laid

CONCRETE IN BARN AND STABLE CONSTRUCTION Barn Foundations. These are laid in the same manner and of the same proportions in the mixture as house foundations, except that there is no cellar unless it is desired.

Barn and Stable Floors. The general

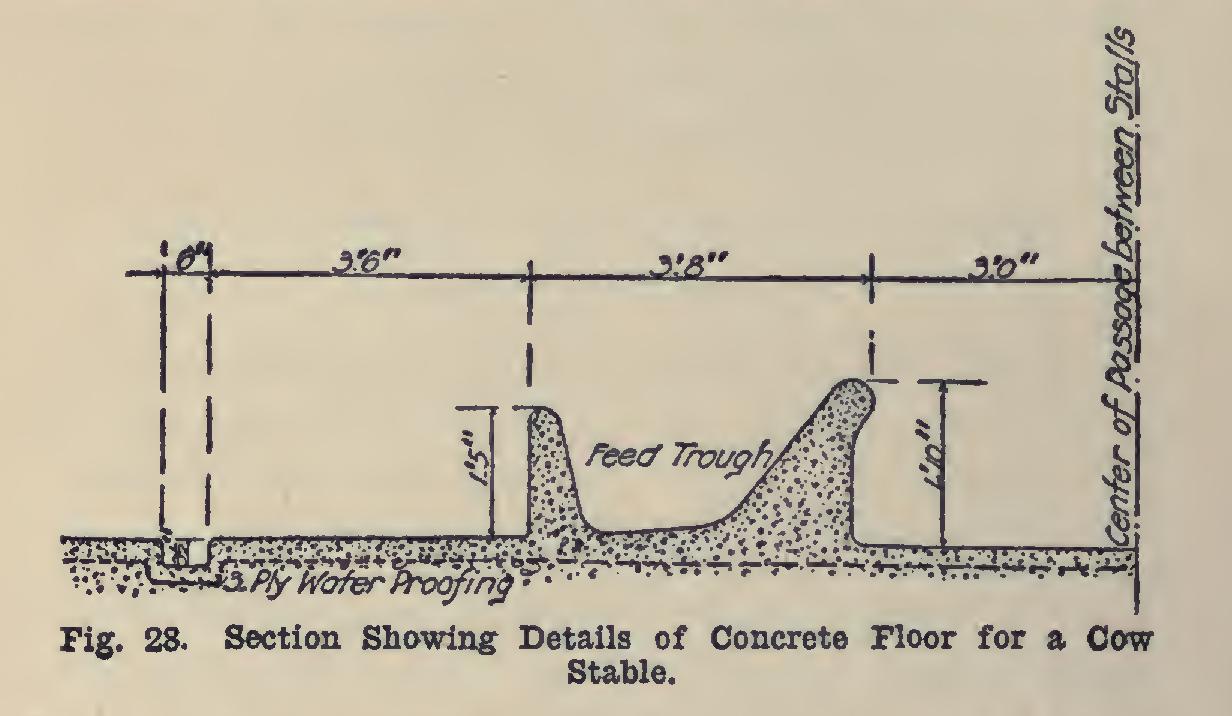

rules of sidewalk construction, given below under the head of "Sidewalk Construction," apply to barn and stable floors. The thickness of the porous sub-base for a barn floor should be 6 inches to 12 inches, the base 3 inches to 5 inches, finishing with a surface of mortar, one part Portland ce meat and one and one-half parts clean, coarse sand, 1 inch to inches thick. This may be roughed at time of laying and before it has set, or grooved in blocks about 6 inches square, to prevent the animals slipping. The surface should have sufficient slope to carry liquids to drains placed at convenient intervals. These drains may be either gutters or pipes laid under the floor, leading to a manure pit. If pipes are used, they should be laid in the sub-base, and the joints put together with cement mortar, care being taken to give the pipes enough slope to flush properly, and making them of straight lengths between openings so that they can be cleaned if necessary. The lids of the drain should be sunk about inch below the level of the floor, and should be loose, so that they can be removed conveniently.

Several years' experience in the use of con crete for barn floors and drains proves that manure will not injure well-made concrete, pro vided the concrete has thoroughly set and hard ened before use.

Driveways are made by dividing into 6-inch squares to give foothold.

The dairyman and agriculturist are more and more coming to recognize the concrete floor as the ideal for barn and stable. Excavation for a stable floor should be made below the frost line, and there should be a sub-foundation of at least six inches, and even more if possible, de pending upon the weight and wear the floor is to have. A deposit of five inches of concrete should be made upon this sub-foundation, con sisting of one part Portland cement, three parts sand, and five parts gravel or crushed stone, well mixed. The top coat should be two inches thick, one part cement and two of sand. The surface

should be so sloped that the liquid manure and water of the stable will flow to some desired point for drainage away. The top should be grooved before it sets, to give the animals foot hold and prevent their slipping. If the floor is to be of more than ordinary size, it should be laid in sections, and provided either with sand joints or the sections separated by pieces of tar paper.

Feeding Floors. The immense advantage of concrete feeding floors over the old method of placing fodder on the ground, is apparent to all who have given the subject any thought. Feed ing floors should be built the same as sidewalks.

The finishing coat is optional, although it has the advantage of being much easier to keep clean. Many farmers prefer an unfinished sur face, on account of its giving cattle a firmer footing in slippery weather.

Box Stalls. There is nothing so warm in winter or cool in summer as a concrete structure. Concrete box stalls are of immense advantage on this account, as they prevent a horse becom ing restive and ill-tempered. They may be built of concrete one part Portland cement, two and one-half parts clean, coarse sand, and five parts broken stone. The walls should be 4 inches thick, and reinforced with one-quarter-inch steel rods 12 inches apart. A smooth surface can be secured by plastering the walls one-eighth inch thick with mortar, one part Portland cement and one part clean, fine sand, after they have been picked with a stone ax and thoroughly wet.

A concrete water box and manger may be built in with the same mixture as the mortar used in plastering. See Plate 1 (lower figure) ; also Plates 10 and 11.