Concrete Retaining Walls

bars, wall, ft, centers, base, horizontal and buttresses

Plate 14 (A) is an illustration of a counter fort retaining wall built by the Lackawanna Railroad in Buffalo, N. Y. This wall was built as part of the Buffalo track elevation work, and is 24 feet high (see Fig. 91). The same type of construction was used for all walls over 12 feet. For walls under 12 feet in height, the section shown in Fig. 92 was adopted.

The reinforcement of the buttressed section consists of both horizontal and vertical bars near the face of the wall, horizontal bars in the base, and inclined bars in the buttresses, square mild steel being used in all cases. Those laid hori zontally in the face of the wall are of ma terial spaced on different centers, farther apart at the top and closer at the bottom, to take care of the increasing pressures toward the bottom of the wall. The vertical bars in the front face are of material spaced throughout on 2-ft. centers. In the back face, five 1/2-M. bars have been placed on 18-in. centers. Tie-rods run from the wall into each buttress, two of them being looped over every third of the hori zontal face bars. They are 6 ft. long, and 1/2 in. square. The heaviest bars used on the work, 11/4 in. square, are used for the diagonals in the buttresses. There are eight of these; but only four run the entire distance from the top of the wall to the outer end of the base, the others start ing at intermediate points. At the bottom of the buttresses, four of the diagonal bars are bent back toward the wall, and are embedded near the under side of the base. Running longitudi nally in the top of the latter are 1-in. square bars, in the outer half of the footings. The rods in the face do not come closer than in. to the surface of the concrete; and those in the but tresses and in the base, not closer than in.

In order to preserve the proper spacing for the horizontal bars in the face a 2 by 2 by angle is placed in the face at each buttress, holes being punched in one leg to hold the bars in their proper positions. They are left in place, and form part of the permanent reinforcement of the wall. The horizontal bars are on 18-in. centers for the first 6 ft. down from the top, on 12-in. centers for the next 6 ft., on 9-in. centers for the next 5 ft. 3 in., and on 6-in. centers for the remainder of the distance to the bottom of the wall.

The reinforcement for the sections below 24 ft. and above 12 ft. in height, is substantially

the same for all sections, except that the base would be moved upward, cutting off the lower part of the reinforcement shown in the diagram, so that from the top down for any given distance the steel will be the same in walls of all heights.

The buttresses are 2 ft. wide, and 12 ft. 6 in. on centers. In the original design it was in tended to place an expansion joint every 25 ft., or on the center line of every second buttress. When construction was started, however, it was found that the wall could be more economically placed in 50 ft. than in 25-ft. sections, and it was therefore decided to place the expansion joints every 50 ft., so that the day's work could be made to terminate at an expansion joint.

All of the horizontal bars are 28 ft. long, while the others, necessarily, are cut to shorter lengths in accordance with their positions. The concrete was a 1:3:6 mixture made with gravel.

For the lower walls without buttresses, the reinforcement is similar to that of the 10-ft. wall in the diagram. For this particular height it consists of 1/2 in. square bars in the base and in both faces of the wall. The vertical bars in the front face are on 2-ft. centers, and the hori zontal bars on 18-in. centers; while in the back face the vertical bars are on 4-in. centers, and the horizontal ones on 18-in. centers. The bars in the base are placed horizontally on 4-in. cen ters, and run from the front of the wall back into footing.

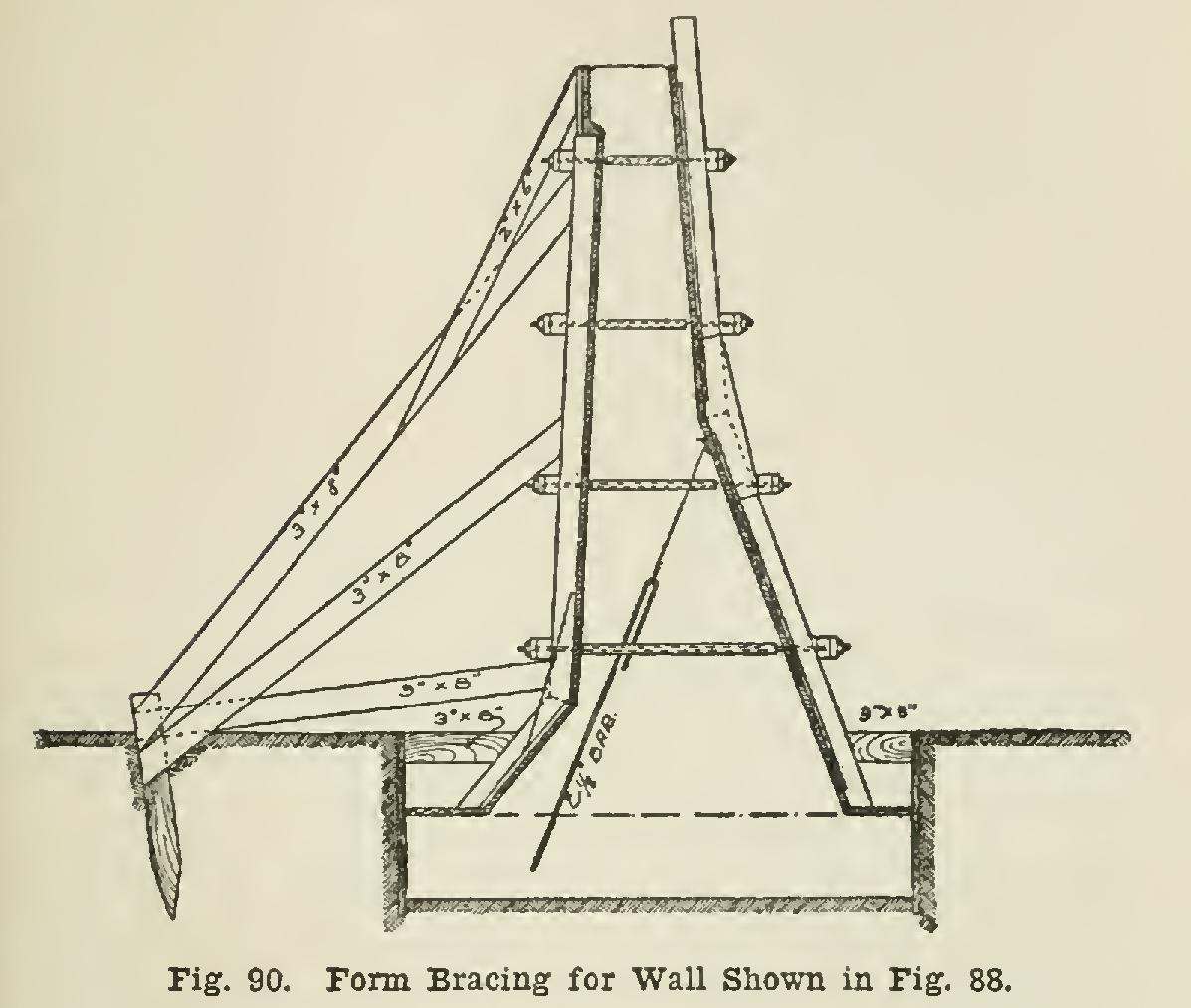

Plate 14 (B) shows clearly the placing of part of the reinforcement before the concrete was cast. As will be noted, great care was exercised in holding the steel in its proper place. A board notched on both sides with the proper spacing for the diagonal bars, was used to prevent the displacement of the steel. Similar notched boards were placed in the base to hold the bars in proper position, and at the upper ends of the diagonal bars in the buttresses. For the latter purpose, the notched piece was nailed to a bracket attached to the front form for the wall. The vertical and horizontal bars, in addition to these precautions, were wired at intersections so as to insure against displacement. The con crete was placed very wet, and on this account long rods threaded at both ends were used to tie the forms together.