Fireproof Construction Floors

cement, concrete, tile, floor, iron, tiles and moulds

2. It should undergo no molecular change in a fire that will impair its strength or change its form.

3. It should be possessed of abundant strength and should be so applied that the expansion and contraction due to rapid heating and sudden cooling will not destroy it or impair its usefulness.

4. It should be a poor conductor of heat.

An excellent combination of all the above named is claimed for several types of reinforced concrete and hollow tile construction as it is to-clay applied. This style of construction, as shown in Plate 14, and Figs. 63 and 100, in the preceding volume—a combination of reinforced concrete joists and hollow tile separators (as they are called)—has recently developed very rapidly as a substitute for solid reinforced con crete. It is claimed that tile floors of this type tend to do away with surface condensation of moisture in the air, due to sudden changes of temperature, since they are of lighter construc tion and respond more quickly to changes than the solid floors.

The tile in this type of floor are set loose upon the centering before the concrete is placed. When the con crete is poured the end joints are imperfectly filled, which is an advantage since the tile have no structural duty to perform, and are thus free to expand when heated, elim inating the possibility of losing their exposed webs, as they are apt to do when built into flat arches.

If the tiles used are porous, they should be thoroughly wet before the concrete is placed, to prevent their soaking up the water in the concrete.

A very notable example of this type of construction is the Marlborough-Blenheim Hotel at Atlantic City, N. J., shown later.

It may be surprising to some to know that reinforcing with cement to secure fireproof floors was practiced in England as early as the middle of the last century, and even earlier. James Frost patented "a new method of casting or con structing floors and ceilings, etc.," in 1822, and the mode of procedure he described as follows: "Ceilings, whether arched or otherwise, are divided into compartments by iron ribs, these being furnished at the lower parts with small rims or mouldings to receive and support such compartments; and the moulds must be surcased (coated) inside before use with some substance which will prevent adhesion thereto of the materials employed for the work, the moulds being removed, of course, as the materials harden.

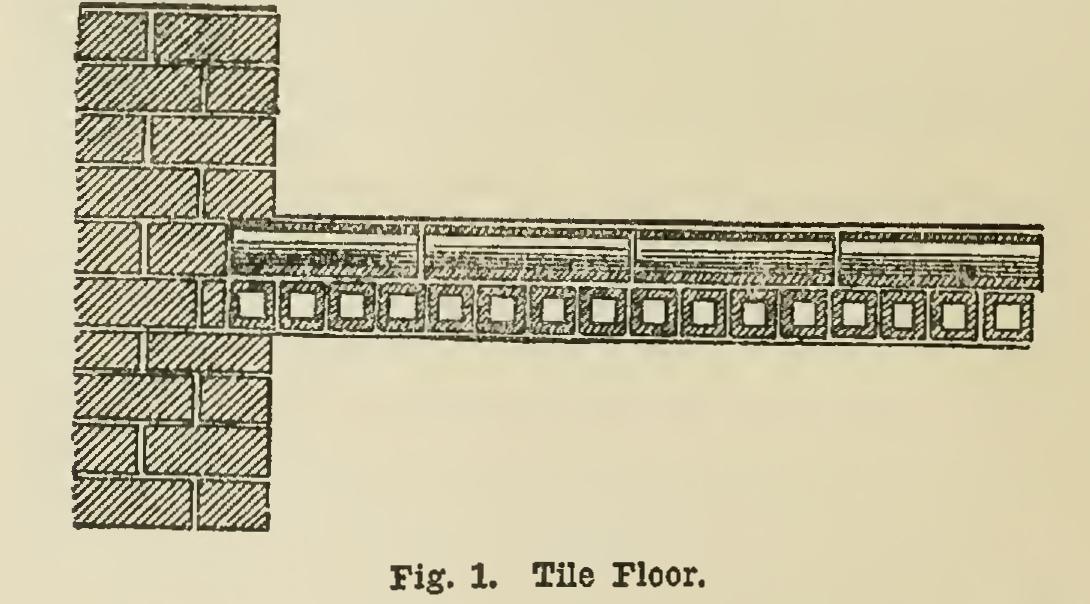

"The moulds are fixed by means of supports or braces in the situation of the structure required, so as to bound exactly the surface of the intended work. The complete structure may then be formed by using a quick-setting calcareous cement, having hard and durable substances embedded therein, as for example, Roman cement mixed with bricks, tiles, stones, gravel, or shingle." When Mr. Frost wrote this description Chi cago was a frontier village. This man was one of the pioneers of the cement industry. He es tablished the first manufactory for the making of Portland cement on the Thames, and in 1840 he introduced another fireproof floor made in the following manner: earthenware tubes two and a-half inches square were made by a ma chine in ten-foot lengths, and, previous to being burned, were cut into one-foot lengths. A cen tering, or platform was erected, upon which two courses of these tubes were laid at right angles to each other, embedded together with neat ce ment. The surface was finished with cement or tiles. This arrangement was said to be suffi ciently strong for any ordinary load up to ten feet between supports (Fig. 1).

Probably Mr. Frost derived his idea of this form of floor from a custom at one time of form ing coverings to areas and forecourts by bedding three courses of roofing tiles together with ce ment, breaking joints as a matter of course, with spans up to eight or nine feet being usual. Lou den in his "Encyclopedia of Cottage and Villa Architecture," published nearly seventy years ago, recommends this arrangement for floors and roofs.

In 1867 Moreland patented a system of floor construction in which curved iron or steel trusses rested on the bottom flanges of iron beams for the purpose of suporting galvanized corrugated iron sheets on which concrete was deposited, and floor-boards nailed to wood strips fixed to the joists. In Fig. 2, a a are steel beams; b, curved truss; d, bricks in a continuous line for the ends of the corrugated sheets to rest on; and e, con crete. The arrangement was varied to suit spe cial requirements, wood ceiling joists being used if necessary.