Fireproof Construction Floors

concrete, floor, fire, joists, fig, wood and experts

The floors constructed of concrete in 1870 and for some years after, were of an ordinary type, concrete deposited on a platform sup ported on wood centers, which were released after an interval of a week or two and used again elsewhere. Spans of twelve feet or more were usual. Some amusing episodes took place when first floors of this character were executed. It was useless to try and persuade workmen that it was quite safe for them to go beneath to strike the centers; one asked seriously if any provision would be made for his family in case he got killed.

Subsequently some adopted the plan of stilt ing the beams (Fig. 3), so as to give a greater thickness of concrete over the joists, where head room permitted, and also flat floors five or six inches in thickness for spans of ten to twelve feet.

The simplest form of concrete floor is formed by fixing steel joists two or three feet apart, and filling in concrete flush with the top and bottom flanges, upheld by a temporary platform or cen tering beneath, as Fig. 4, which came into use almost simultaneously with the adoption of con crete walls, 1865-6.

But as with walls, so with floors; very little care or common sense was taken in their con struction, and with the usual result; one at Ports mouth collapsed in 1876, killing four workmen who were beneath; similar accidents took place in other parts of the country, and concrete got a bad reputation.

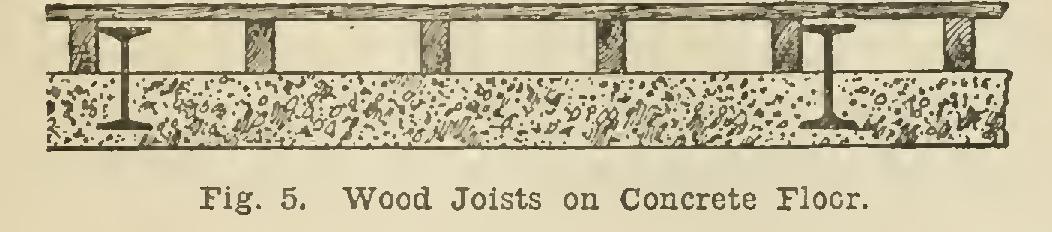

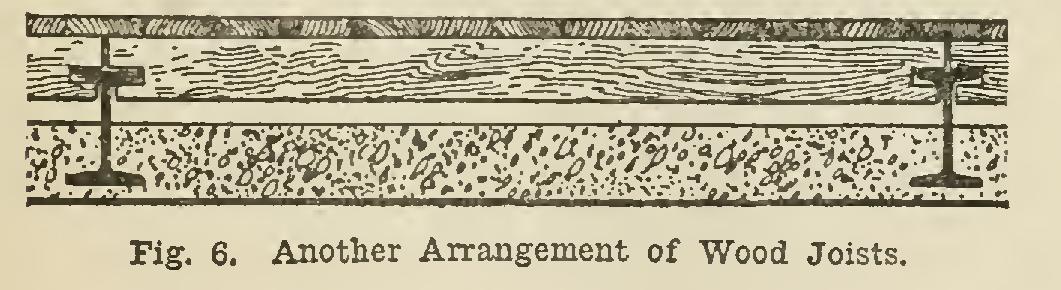

Where the joists were much deeper than was required for the concrete filling, earthenware tubes were sometimes embedded longitudinally in the concrete, a system based on Beadmore's invention in 1848, for reducing the weight of the floor. Another method to effect the same object was to fix wood joists on top of the concrete (as in Fig. 5), a very simple arrangement which would occur to most people, but which could scarcely be called a fire-resisting floor but a fire-resisting ceiling, which in case of fire might prevent its upward progress. Still another method was to notch the wood joists over the steel joists with a view of giving some elasticity to the floor (Fig. 6). Neither of these arrangements pre vented dirt, dust, and floor washings from find ing their way through the joints of the floor boards, and there finding a resting place for generations to come; and from a sanitary point of view, they were no improvement on the wood joist and ordinary floor board system.

Concrete and reinforced concrete structures have been given the highest endorsement any building material ever received—that of the gov ernment itself. The United States Geological Survey issued a bulletin calling attention to the report of the commission of experts appointed shortly after the San Francisco earthquake and fire to investigate fireproofing. As indicated in the bulletin, concrete is accorded first honors among fireproof materials.

Investigations made by three of the most competent structural experts in the country have led them to the conclusion that there are no absolutely fireproof buildings. Not that fire proof buildings are impossible, for, according to these experts, structural materials may be so selected and used that adequate fire protection is practically assured; but in the effort to cheapen construction in order to obtain greater interest on investments, owners of buildings have neglected or ignored perils to lives and fortunes.

The recommendations of the experts as to the essentials of fireproof construction are definite and positive. High, steel-frame office buildings, properly braced, are declared to be stable and reliable, and concrete and reinforced concrete structures are placed high among materials well adapted to withstand earthquake and fire; while hollow tiles and hollow concrete, although not in the past universally successful, may be so em ployed as to yield most satisfactory results. Concrete floors with metallic mesh reinforce ments are strongly recommended for strength and fire-resistance; and wire glass, metallic roll ing shutters, and metal sash have proved such excellent fire protectors that wise economy de mands their use in every important building.

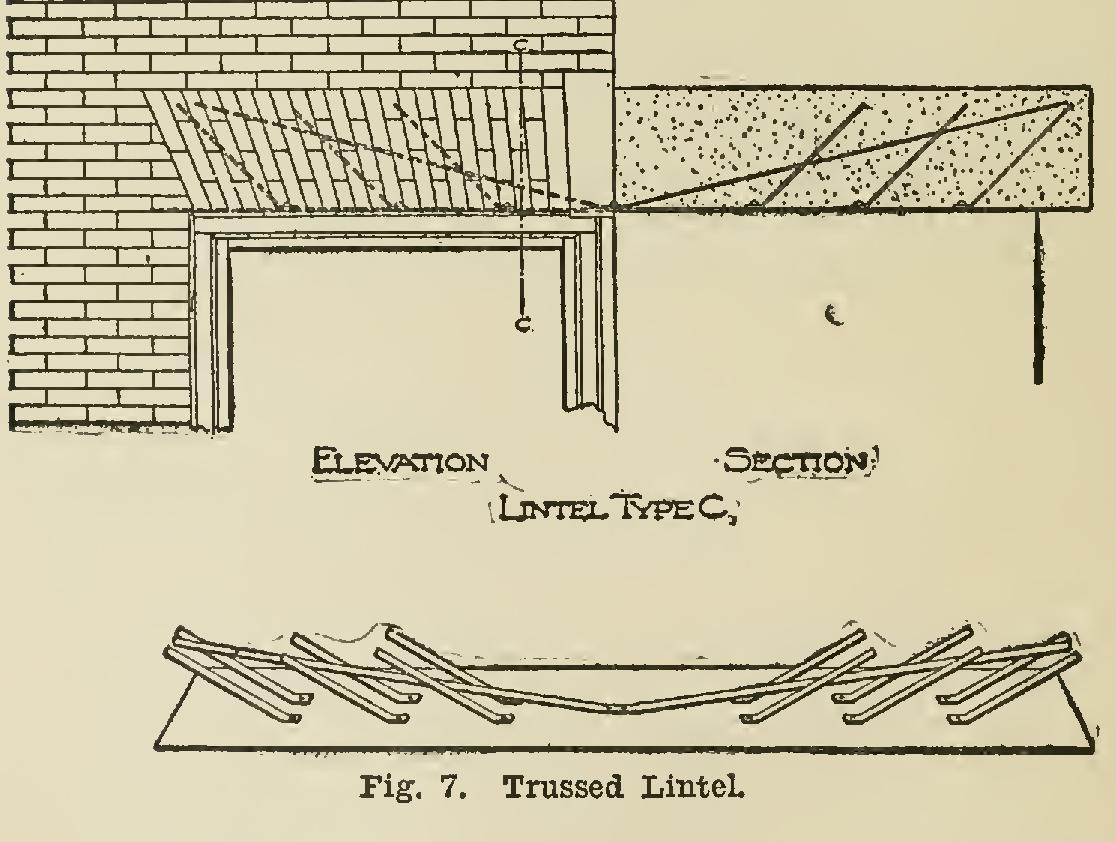

Plate 1 shows a detail of window framing into a reinforced concrete lintel beam; while Fig. 7 shows a trussed lintel which is claimed to be cheaper than structural steel and more effective.

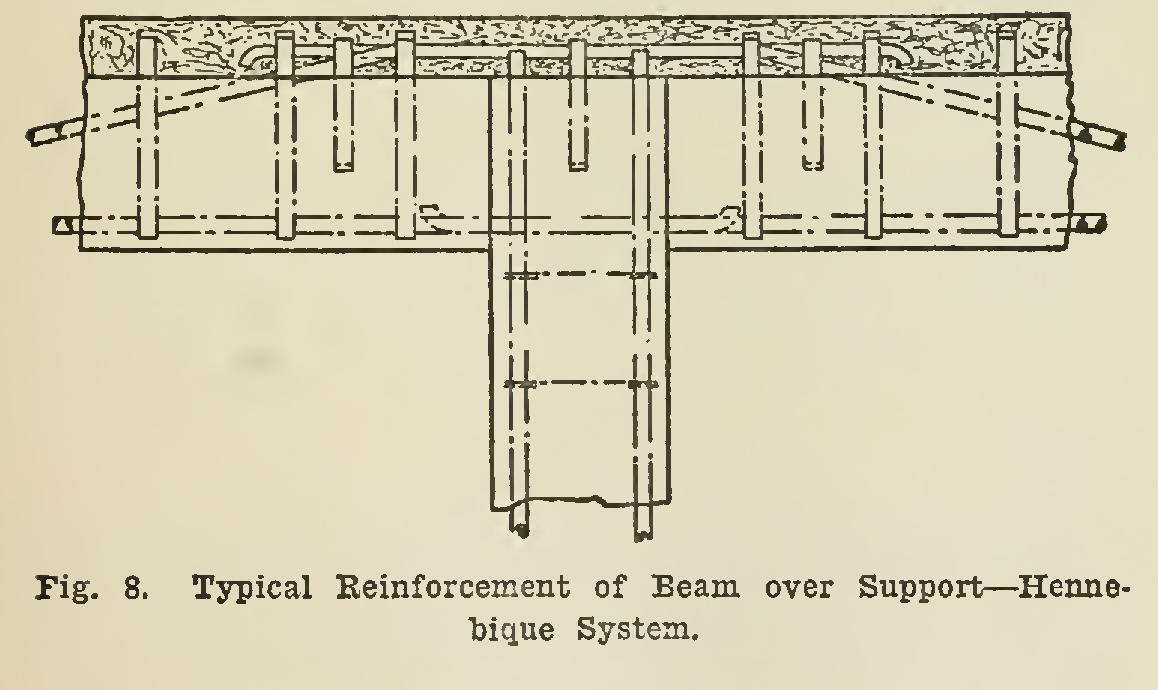

Fig. 8 shows a common way of extending reinforcing rods over a support in case of con tinuous floor construction. The top rods take the tension over the supports when the floor tends to deflect or bend in center of span be tween girders.