Girder and Slab Bridges

concrete, spans, sand, feet, mortar, crossings and stone

Gravel when used should be composed of clean pebbles free from any foreign matter, and containing no clay nor any materials adhering to the pebbles.

It should be screened to remove the sand, and should be mixed afterwards in the proper pro portions. However, if by tests, the gravel runs in the proportions of two and one-half to three parts sand, to four or five parts of pebbles, it can be used without screening.

Broken stone should consist of pieces of hard, durable rock, such as limestone or conglomerate.

The water should be clean and free from acids or strong alkalies.

Steel for reinforcement should be of high ten sile strength, and of such shape as to form a firm mechanical bond with the concrete.

In mixing concrete for highway bridges or culverts, proportions should be used to give the densest concrete with the maximum strength of the concrete.

The mortar mixture of sand and cement is generally two parts of sand to one part of ce ment; yet mixtures of two and one-half to three parts of sand to one of cement will give a mortar that is dense and for practical purposes as good on small bridges and culverts as stronger mixtures.

The stone aggregate should not be more than twice that of sand; and in most cases the propor tion of four parts of stone will generally make the most desirable mixture, as it allows sufficient mortar to cover all the stone and leaves no rough spots on the surface.

Mix well and mix wet will cure many faults, so-called, in working with concrete.

Exposed surfaces of concrete may be made sufficiently smooth by spading, so as to force the stones back from the surface and allowing the mortar to crowd to the face; the forms should be sufficiently tight to prevent mortar running out. With these precautions, surfaces can be obtained that require very little patching or plastering to make a neat job.

The forms should be made of lumber suf ficiently strong to hold itself in line without an excess of bracing, and not bulge or be thrown out of line by the workmen filling them. All exposed surfaces should be made with dressed lumber, with all joints neatly fitted. The lumber best adapted for building the forms is 2x6-in. stuff with 4x4-in. for the stays.

The handiest ties are one-half-inch bolts of a length necessary to hold the forms together.

Bolting the forms requires few nails, and makes a form that can be taken down easily.

The time necessary to leave the forms in place varies considerably with the weather. But under ordinary conditions, wing walls and cul vert walls can be removed in three days. Slabs of not more than six feet may be removed in five days. Longer spans and arches up to forty feet, require not less than ten days of good drying weather.

In freezing weather, the forms should be left in place as long as possible.

The State Highway Commission of Illinois furnishes advice to township and county high way officials throughout the State in regard to bridges as well as roads; and in many instances, at the request of local authorities, has supplied plans and specifications for the needed struc tures, and has taken charge of the letting of con tracts. According to the annual report of the Commission, reinforced concrete bridges are rec ommended for spans up to 50 feet.

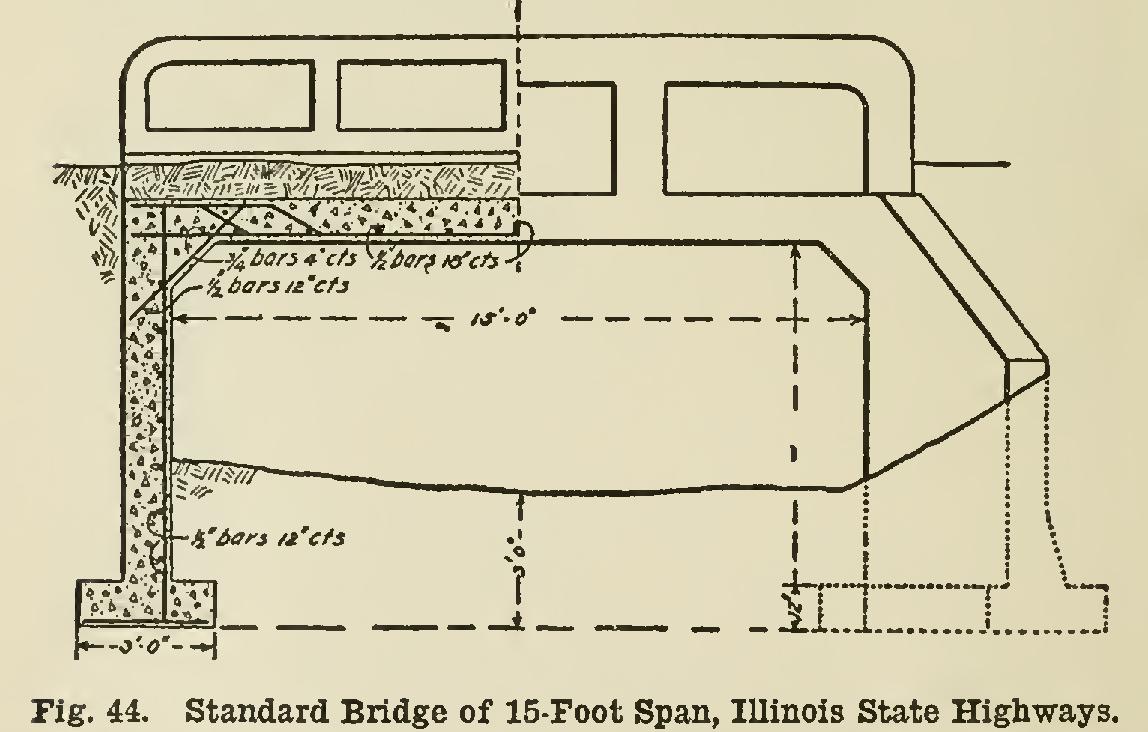

In Fig. 44 is shown the standard form of bridge adopted by the Commission for spans up to 18 feet. This is a slab bridge, and the main reinforcement is in the direction of the span. The parapets do not carry any of the load.

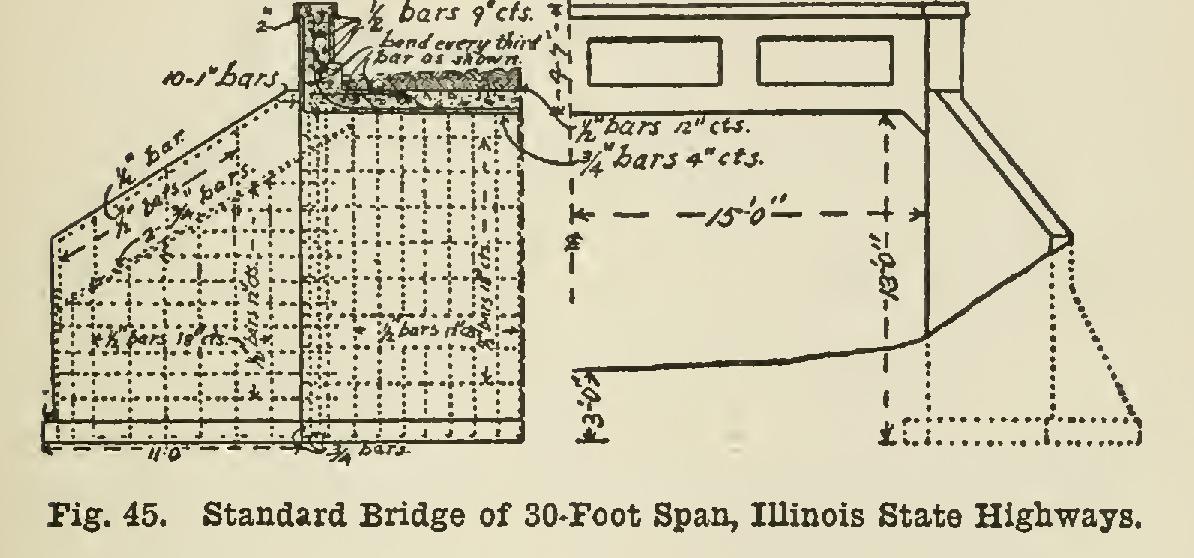

In Fig. 45 is shown a girder bridge recom mended for spans up to 50 feet. In this type the load is carried to the abutments by means of the side girders, which also serve as parapets or railings. The floor slab spans between these girders.

Plate 6 (A and illustrates typical country highway bridges. The bridge shown in Plate 6 (A) spans 35 ft. between abutments. It is 18 ft. wide; and the floor spans between the two out side girders, which carry the load to the abut ments.

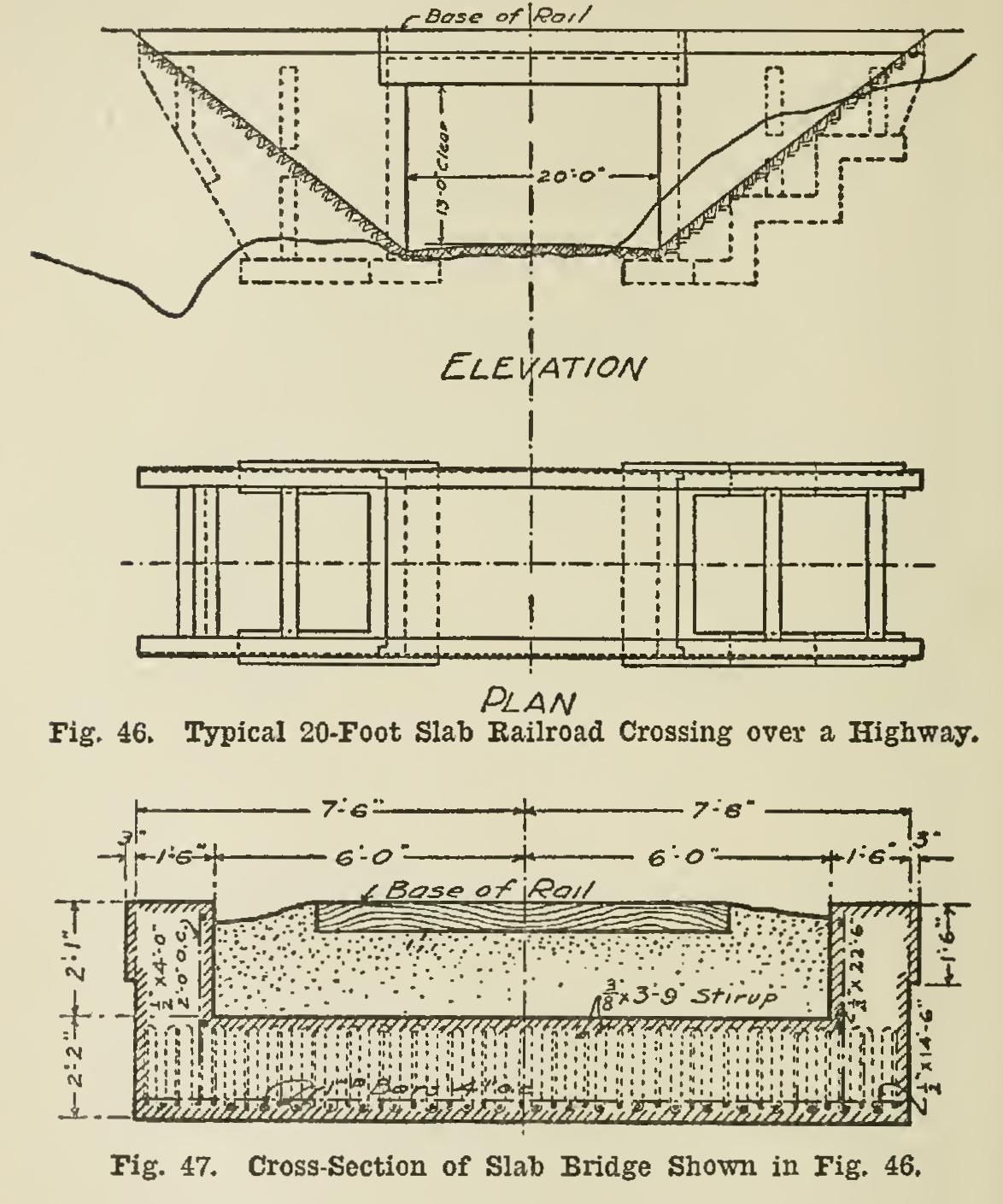

Railway Girder and Slab Bridges. Rein forced concrete slab and girder construction is well adapted to short-span railway bridges, and is extensively used for such structures. Short span bridges in railroad work are required for a number of purposes—as street crossings, high way crossings, small stream crossings, trestles, cattle-passes, and culverts. Street crossings are described under the heading "Track Elevation Bridges;" and trestles and culverts are treated under their respective class names.