Placing of Forms

columns, boxes, girders, inches, buildings, beams, girder, centering and lateral

"It is one thing to design a form for centering, and another to make one that is practical and that can be made on modern machinery at reasonable cost. The thing we must strive for is the minimum amount of steel and labor required to produce a centering that will give maximum results. And this we have attempted to do by forming up sheet steel into certain standard forms so that they may be adjusted to different-sized spans or bays without cutting or fitting.

"The one great drawback to producing a uniform cen tering is the disregard of uniform spacing of columns, girders, and beams for certain types of buildings, and of regulating the height of stories. It would appear that the greatest stride that could be made for the success of concrete construction would be to adopt a series of standard sizes and spacings of columns and girders for certain types of buildings. If this could be accomplished, it would materially reduce the cost of all such buildings, as certain engineers and contractors would equip them selves with the necessary appliances to erect these build ings at the minimum cost; and again, other contractors would equip for other classes of buildings which seem best suited to their likings. In this way the whole field would be covered and the very best results obtained, and at the same time the investor would reap the benefit of the cost reduction, and all would be happy.

"Centering can be confined to three types, as follows: "First, the floors where the whole area interlying four columns is flat on the under side; second, where the area is broken up by two cross-beams into three panels ; and third, where the area is divided up by a series of concrete ribs or joists. In all cases the columns may be either round or square, with brackets or plain, and the carrying girders between the columns dropped below the cross beams, ribs, or interlying area. The sizes of columns and girders should be restricted to four depths and widths for buildings of ordinary design, with a variation of two inches in height for girders and beams, and four inches for diameter of columns, eight inches being the minimum and fourteen the maximum for girder boxes, and four inches the minimum and ten inches the maximum for lateral beam boxes; width of girders and beams in pro portion to depth to be determined. Columns may range from twelve inches to twenty-four, with four inches variation—that is, 12-16-20-24 inches. These sizes could be adapted to almost any type of buildings where light or heavy floor loads are to be carried.

"Again, the variation in height of stories shou14:1 restricted, allowing four different heights to apply to dif ferent classes of buildings.

"Mercantile buildings can be divided into three classes —namely, office, wholesale, and warehouse ; manufactur ing into two—light and heavy ; miscellaneous, such as schools, theaters, churches, and dwellings, into two. If

this could be accomplished you can readily see that it would simplify the whole matter, for both the engineer and the contractor, as well as for the manufacturer of centering. The engineer would determine the size of columns, girders, and beams by the loads to be carried, by referring to the table for certain spacings ; and the contractor would only need to invest in two or three sizes of forms or centering to construct any one type of building. It would resolve itself into contractors con fining their operations to certain types, which would be a good thing, both financially and structurally.

"Taking matters as they stand to-day, sheet steel for centering purposes will compare favorably with wood in first cost, and the great saving in labor in putting it to place is certainly apparent to everyone who has seen the steel centering.

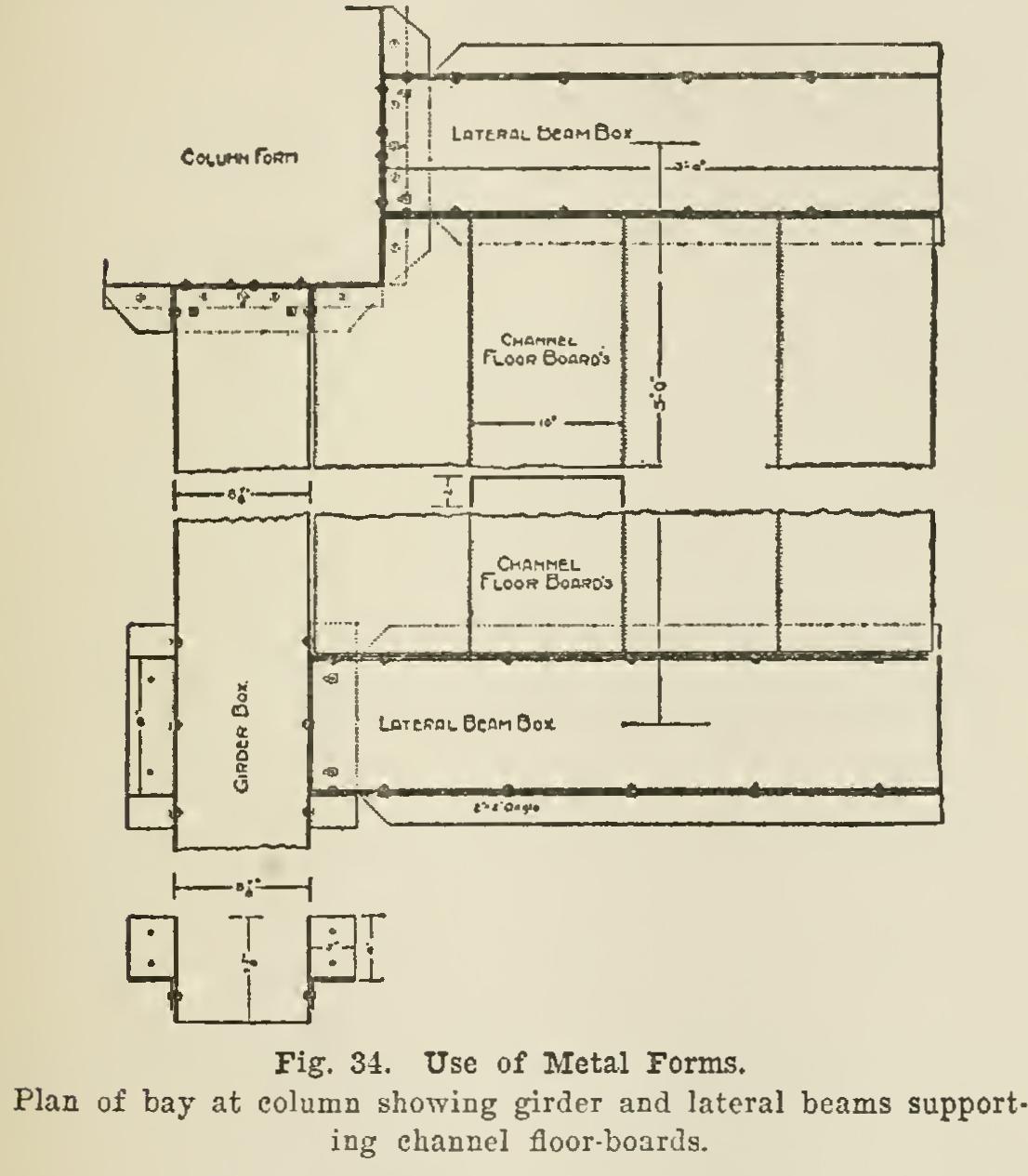

"The steel may be shaped for forming either round or square columns, so that they can be removed without injury and in one-fourth the time it takes to remove wooden forms. For each type of construction, the girder boxes are attached to the column forms, and the lateral beam boxes in turn to the girder boxes (see Fig. 34), the distance from the center of the column to the first lateral beam is fixed, say five feet; and the distance between the two lateral beams is variable, to allow for spacing of columns. The lateral boxes carry the flooring over the whole intercolumn area, so that when all are in place the column form, girder boxes, lateral beam boxes, and flooring are level and even, allowing for a uniform slab of concrete over the whole area, bonding with the columns, girders, and beams, and making a. homogeneous mass.

"After the concrete has hardened, the cross-beam boxes are dropped, then the steel floor bonds, next girder boxes, after which the column forms are taken off, leaving a dean, even, well-formed surface. As soon as the cen tering is removed, it should be examined, and, if bent or dented, straightened, and the surface thoroughly brushed at once and given a coat of oil or soft soap, so that they are ready for use again and not left for the particles of concrete to harden on the surface, after which it would take five times as much trouble and labor to put them into working order.

"We do not rely on the girder and cross-beam boxes to carry the dead load of the concrete, but rely on adjust able posts to support them in the middle until the con crete is thoroughly hard. The girder box form is so arranged that the post need not be disturbed while the box is being removed, so that there is no danger of acci dent or failure taking place while tearing down."